Marbleized quartzite plate and preparation method thereof

A quartz stone plate and marble pattern technology, applied in the field of home improvement building materials manufacturing, can solve the problems of low product hardness, complex and cumbersome preparation process, poor strength, etc., and achieve the effects of excellent products, overcoming complex process and good toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 quartz stone mixture

[0029] The components and the content of each component in the marble pattern mixture and the board main mixture are basically the same, the difference is only in the addition of pigments.

[0030] In parts by weight, the quartz stone mixture includes the following components:

[0031] Acrylic resin 5-20 parts, quartz sand 65-80 parts, silane coupling agent 0.1-5 parts, curing agent 0.1-5 parts, pigment 0-5 parts, fiber 1-20 parts. The above materials are common commercially available materials.

[0032] Quartz sand is made of quartz stone or silica powder with a particle size of 40-3000 mesh.

[0033] The silane coupling agent is γ-(methacryloxypropyl)trimethoxysilane, γ-(2,3-epoxypropoxy)propyltrimethoxysilane, N-β(aminoethyl)- γ-Aminopropylmethyldimethoxysilane, N-(β-aminoethyl)-γ-aminopropyltriethoxysilane, N-β(aminoethyl)-γ-aminopropyltrimethoxy ylsilane, anilinomethyltriethoxysilane, γ-aminopropyltriethoxy...

Embodiment 2

[0043] Embodiment 2 The preparation of the quartzite plate material imitating marble pattern

[0044] The preparation of the marble-like quartz stone plate in the present embodiment is carried out according to the following steps:

[0045] Step S1: Style Design

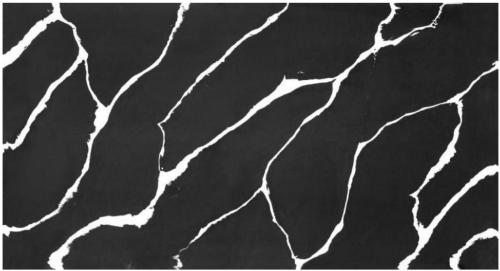

[0046] Design the color of the body of the slab and the color and texture of the marbling in the quartz stone slab. The color of the board body in this embodiment is black, and the color of the marble pattern is white.

[0047] Step S2: Prepare the mold

[0048] Prepare a pattern mold and a quartz stone plate mold according to the style of the quartz stone plate designed in step S1.

[0049] Step S3: Prepare materials

[0050]According to the style of the quartz stone plate designed in step S1, the marble pattern mixture and the main body mixture of the plate are prepared.

[0051] The preparation process in this embodiment is carried out according to the formula and preparation method described in Example 1.

...

Embodiment 3

[0059] The marble pattern mixture in this embodiment includes the following components: 20 parts of acrylic resin, 65 parts of quartz sand, 1 part of silane coupling agent, 3 parts of curing agent, 3 parts of white pigment, and 8 parts of fiber.

[0060] The board main compound includes the following components: 20 parts of acrylic resin, 65 parts of quartz sand, 1 part of silane coupling agent, 3 parts of curing agent, 3 parts of black pigment, and 8 parts of fiber.

[0061] The silane coupling agent in this embodiment is γ-(methacryloxypropyl) trimethoxysilane and / or γ-(2,3-glycidoxy)propyltrimethoxysilane, curing agent Di(4-tert-butyl)cyclohexyl peroxydicarbonate and / or dilauroyl peroxide.

[0062] The preparation method is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com