Insulating box coating technology for solid insulation switch equipment

A solid insulation switch, solid insulation technology, used in coatings, epoxy resin coatings, devices for coating liquids on surfaces, etc. Good insulation, not easy to crack and rust, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

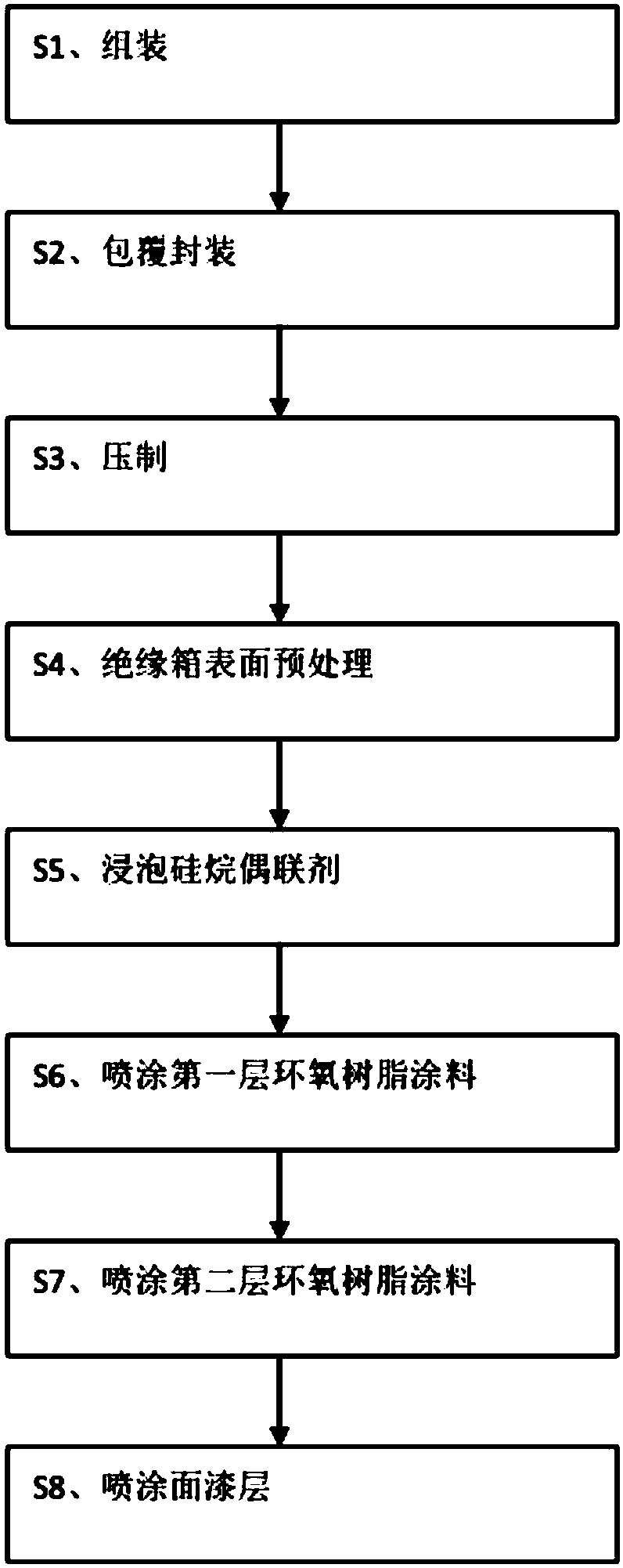

[0034] Please see figure 1 , is a flow chart of a preferred embodiment of the coating process for a solid insulated switchgear insulation box of the present invention, including the following steps:

[0035] S1. Assembly: Assemble the three-phase vacuum interrupter and its corresponding conductive connections, isolating switch, grounding switch, main busbar, branch busbar and other main conductive circuits respectively;

[0036] S2. Encapsulation: Encapsulate the assembled three-phase interrupter and its corresponding conductive parts with a solid insulating medium to form an insulating box shell;

[0037] S3, pressing: preheating the pressing mold, after the preheating is completed, use the pressing mold to press the surface of the insulating box shell, and after the pressing is completed, cool and demould the insulating box;

[0038] S4. Pretreatment of the surface of the insulation box: Use water-based biodegradable cleaners to remove oil, water, grease, salt, etc. on the ...

Embodiment 2

[0065] A preferred embodiment of the coating process of the insulation box of the solid insulation switchgear of the present invention comprises the following steps:

[0066] S1. Assembly: Assemble the three-phase vacuum interrupter and its corresponding conductive connections, isolating switch, grounding switch, main busbar, branch busbar and other main conductive circuits respectively;

[0067] S2. Encapsulation: Encapsulate the assembled three-phase interrupter and its corresponding conductive parts with a solid insulating medium to form an insulating box shell;

[0068] S3, pressing: preheating the pressing mold, after the preheating is completed, use the pressing mold to press the surface of the insulating box shell, and after the pressing is completed, cool and demould the insulating box;

[0069] S4. Pretreatment of the surface of the insulation box: Use water-based biodegradable cleaners to remove oil, water, grease, salt, etc. on the surface of the insulation box, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com