Gas steam generating equipment

A technology for generating equipment and gas steam, which is applied in steam generation, steam boilers, lighting and heating equipment, etc. It can solve problems such as too many assembly joints, dry heat exchangers, and insufficient heat absorption, so as to prevent thermal deformation and damage, increase The effect of increasing the heat exchange pipeline path and heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] For better understanding and implementation, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

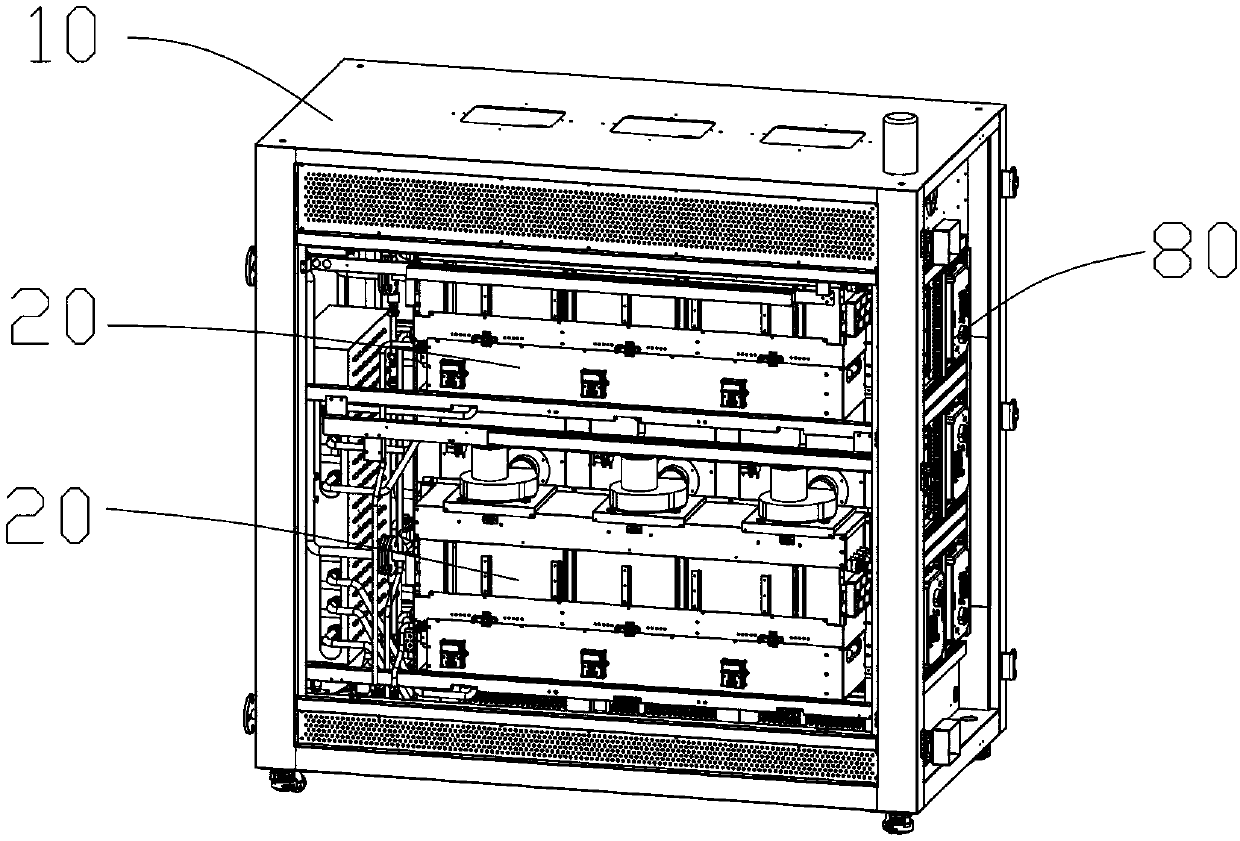

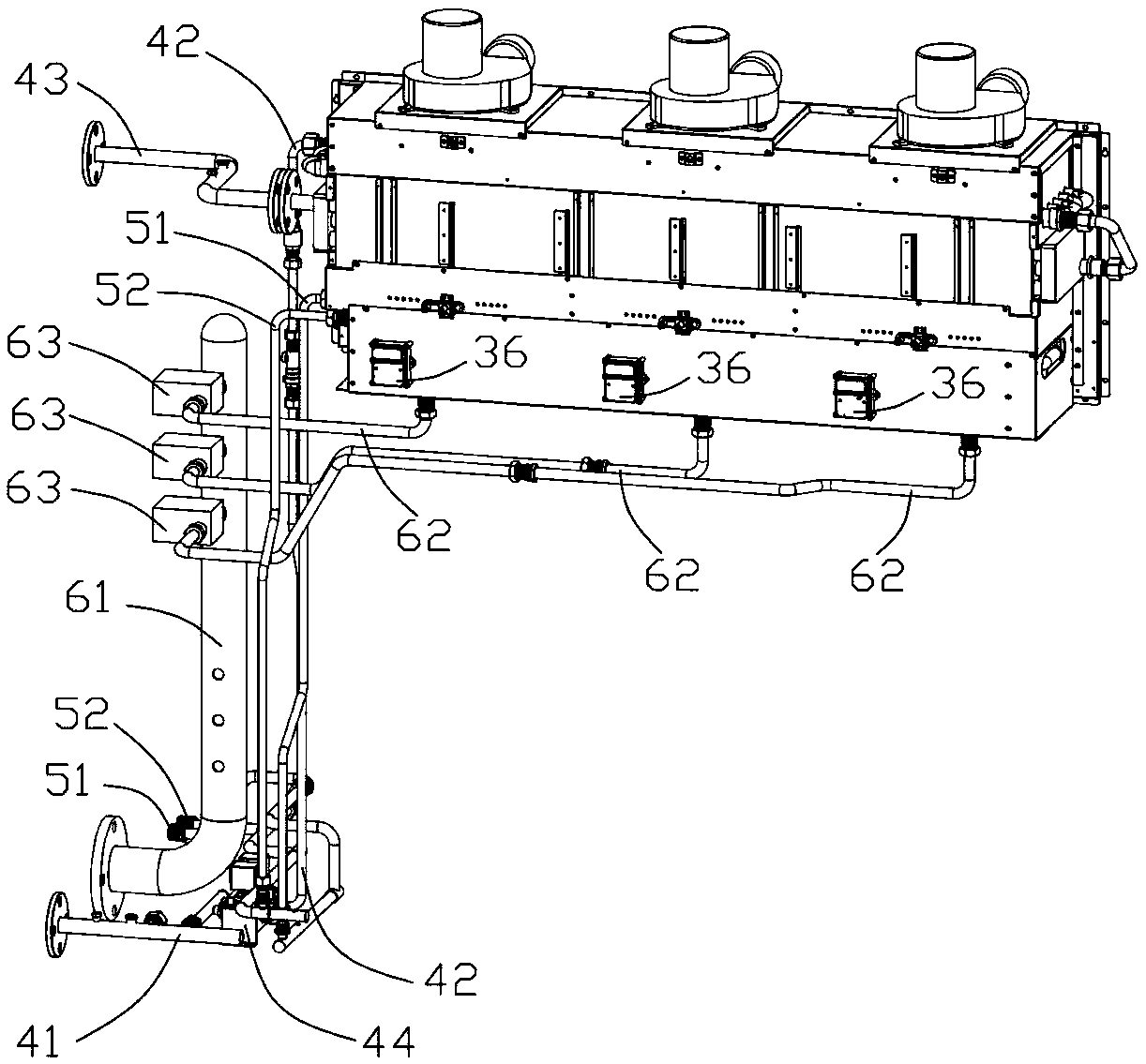

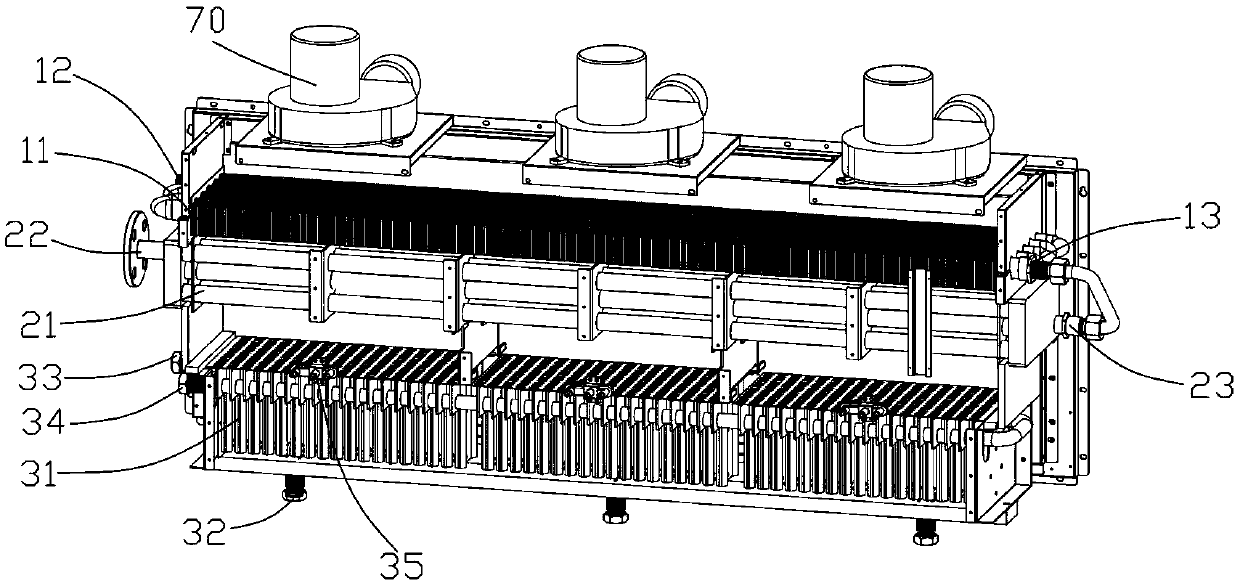

[0050] The invention discloses a gas steam generating device, such as Figure 1-3 As shown, it includes a frame 10 and more than one set of steam generating modules 20 arranged in the frame 10. In this embodiment, the number of the steam generating modules 20 is 4 groups, and they are arranged up, down, left, and right on the Inside the frame 10; the steam generating module 20 includes a combustion chamber and a finned heat exchanger 11, a shell-and-tube light tube heat exchanger 21 and a low-nitrogen fire exhaust burner arranged in the combustion chamber from top to bottom in sequence 31; one end of the finned heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com