Method for preparing inositol-1-phosphate

A technology of inositol and phosphoric acid, which is applied in the field of preparation of inositol-1-phosphate, can solve the problems of no industrial value, high price, high production cost, etc., and achieve large-scale production, low production cost and high utilization rate of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0036] Experimental example 1 in vitro multi-enzyme catalyzed conversion of starch into inositol-1-phosphate

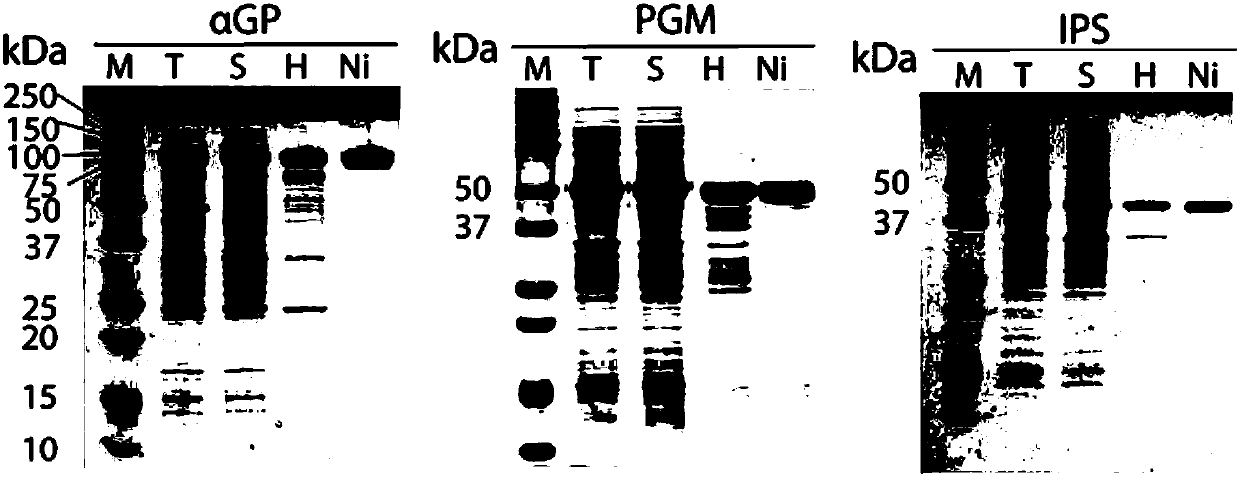

[0037] Starch was converted into inositol-1-phosphate ( figure 1 ). These key enzymes include: (1) starch phosphorylase (αGP, EC 2.4.1.1), which releases glucose-1-phosphate from starch; (2) glucose phosphomutase (PGM, EC 5.4.2.2), which catalyzes Glucose-1-phosphate generates glucose-6-phosphate; (3) inositol-1-phosphate synthase (IPS, EC 5.5.1.4), which catalyzes the generation of inositol-1-phosphate from glucose-6-phosphate. Since the last enzyme reaction is an irreversible reaction, the conversion rate of the enzyme-catalyzed system is very high.

[0038] In the present invention, starch phosphorylase and glucose phosphate mutase are derived from Thermotoga maritima, and the gene numbers on KEGG are TM1168 and TM0769 respectively, and inositol-1-phosphate synthase is derived from Archaeoglobusfulgidus, and the gene numbers on KEGG For AF1794, these genomic DN...

experiment example 2

[0045] Experimental example 2 in vitro multi-enzyme catalyzed conversion of starch into inositol-1-phosphate (reaction at different temperatures)

[0046] The preparation of starch phosphorylase, glucose phosphomutase and inositol-1-phosphate synthase was the same as in Experimental Example 1.

[0047] In a 1.0mL reaction system containing 200mM sodium phosphate buffer (pH 7.2), 5mM divalent magnesium ions, 0.5U / mL starch phosphorylase, 0.1U / mL glucose phosphomutase, and 0.5 U / mL inositol-1-phosphate synthase, 20g / L soluble starch, catalyzed reaction at 80°C, and the reaction time was 72 hours.

[0048] After the reaction, the final concentration of inositol-1-phosphate was 6.4g / L, and the conversion rate to starch was 32%.

experiment example 3

[0049] Experimental Example 3 Improve the yield of inositol-1-phosphate through process optimization and adding enzymes that promote starch hydrolysis

[0050] Since starch phosphorylase cannot completely hydrolyze starch, the yield of inositol-1-phosphate is limited. Therefore, we added isoamylase (isoamylase, EC 3.2.1.68) that can help starch hydrolysis in the reaction system. Under the double action of starch phosphorylase and isoamylase, the end products of starch hydrolysis are maltose and glucose. In order to convert these products into inositol-1-phosphate, maltose phosphorylase (maltose phosphorylase, EC 2.4.1.8) and polyphosphate glucokinase (polyphosphate glucokinase, EC 2.7.1.63) need to be added.

[0051] In the present invention, the isoamylase is derived from Sulfolobus tokodaii, and the number of the gene on KEGG is ST0928, and the genome DNA of this bacterial strain is German Albert-Ludwigs- Courtesy of Prof. Georg Fuchs, Freiburg. Polyphosphoglucokinase is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com