Telescopic hose and preparation method thereof

A telescopic hose and joint technology, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of ignoring wear resistance, loss of tensile performance aging, and pipe tensile fatigue, so as to avoid loss of elasticity and improve strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

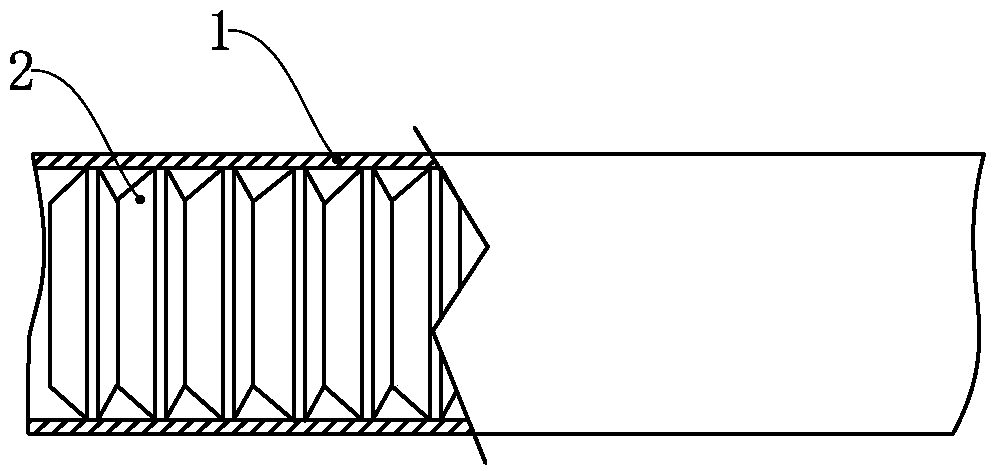

[0034] A telescopic hose, the telescopic hose at least includes an outer pipe body and an inner pipe body that are combined; Engage the top of the thread.

[0035] The material of the outer tube body is a modified TPE thermoplastic elastomer, including the following raw material components in parts by weight: 100 parts of TPE thermoplastic elastomer, 3 parts of silicon dioxide SiO 2 , 0.9 parts of antistatic agent; the material of the inner pipe body is modified polyvinyl chloride, including the raw material components of the following parts by weight: 100 parts of polyvinyl chloride PVC; 25 parts of ethylene propylene diene rubber EPDM, 16 parts of nitrile rubber NBR, 0.4 parts of stabilizer, 30 parts of dimethyl phthalate DOP, 12 parts of dioctyl adipate DOA, 0.7 parts of PE wax.

Embodiment 2

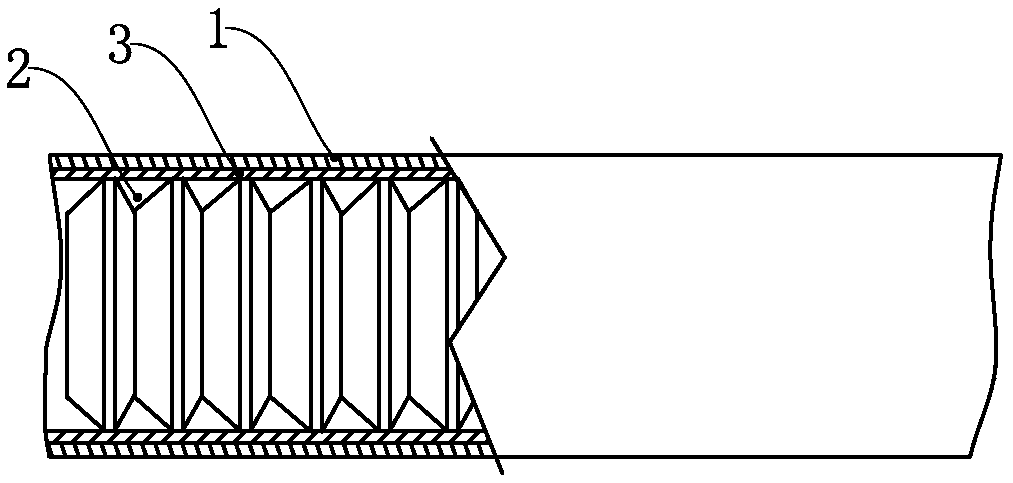

[0037] A telescopic hose, the telescopic hose at least includes an outer tube body and an inner tube body that are combined together; there is an intermediate tube body between the outer tube body and the inner tube body; the inner tube body is a corrugated inner tube A pipe body, the inner wall of the intermediate pipe engages with the threaded top of the corrugated inner pipe body.

[0038] The material of the outer tube body is a modified TPE thermoplastic elastomer, including the following raw material components in parts by weight: 100 parts of TPE thermoplastic elastomer, 4 parts of silicon dioxide SiO 2 , 0.5 parts of antistatic agent; the material of the intermediate pipe body and the inner pipe body is modified polyvinyl chloride, including the raw material components of the following parts by weight: 100 parts of polyvinyl chloride PVC; 15 parts of tertiary ethylene Propylene rubber EPDM, 15 parts of nitrile rubber NBR, 0.6 parts of stabilizer, 20 parts of dimethyl p...

Embodiment 3

[0040] A telescopic hose, the telescopic hose at least includes an outer tube body and an inner tube body that are combined together; there is an intermediate tube body between the outer tube body and the inner tube body; the inner tube body is a corrugated inner tube A pipe body, the inner wall of the intermediate pipe engages with the threaded top of the corrugated inner pipe body. Between the inner tube body and the middle tube body, a reinforcing and limiting fiber line is arranged, and the reinforcing and limiting fiber line is a plurality of rows of winding wires arranged in rotation at a certain angle along the circumferential direction of the tube body.

[0041] The material of the outer tube body is a modified TPE thermoplastic elastomer, including the following raw material components in parts by weight: 100 parts of TPE thermoplastic elastomer, 6 parts of silicon dioxide SiO 2 , 0.8 parts of an antistatic agent; the material of the intermediate pipe body and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com