A kind of floating magnetic polymer composite material and its preparation method and application

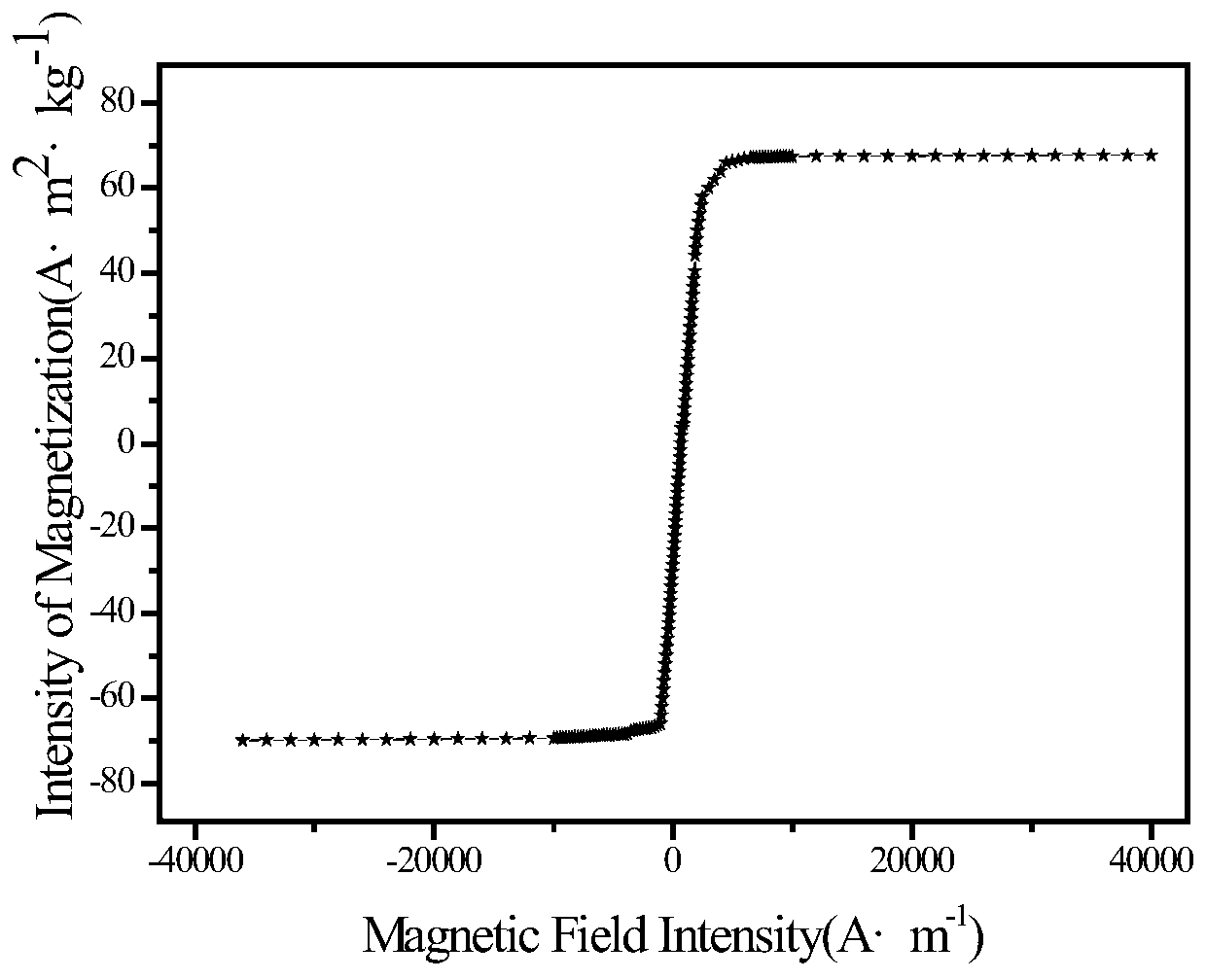

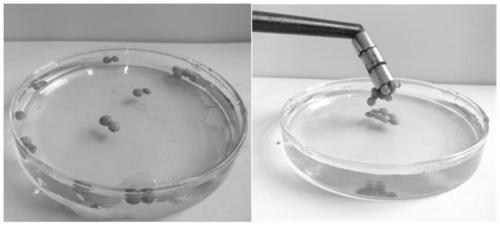

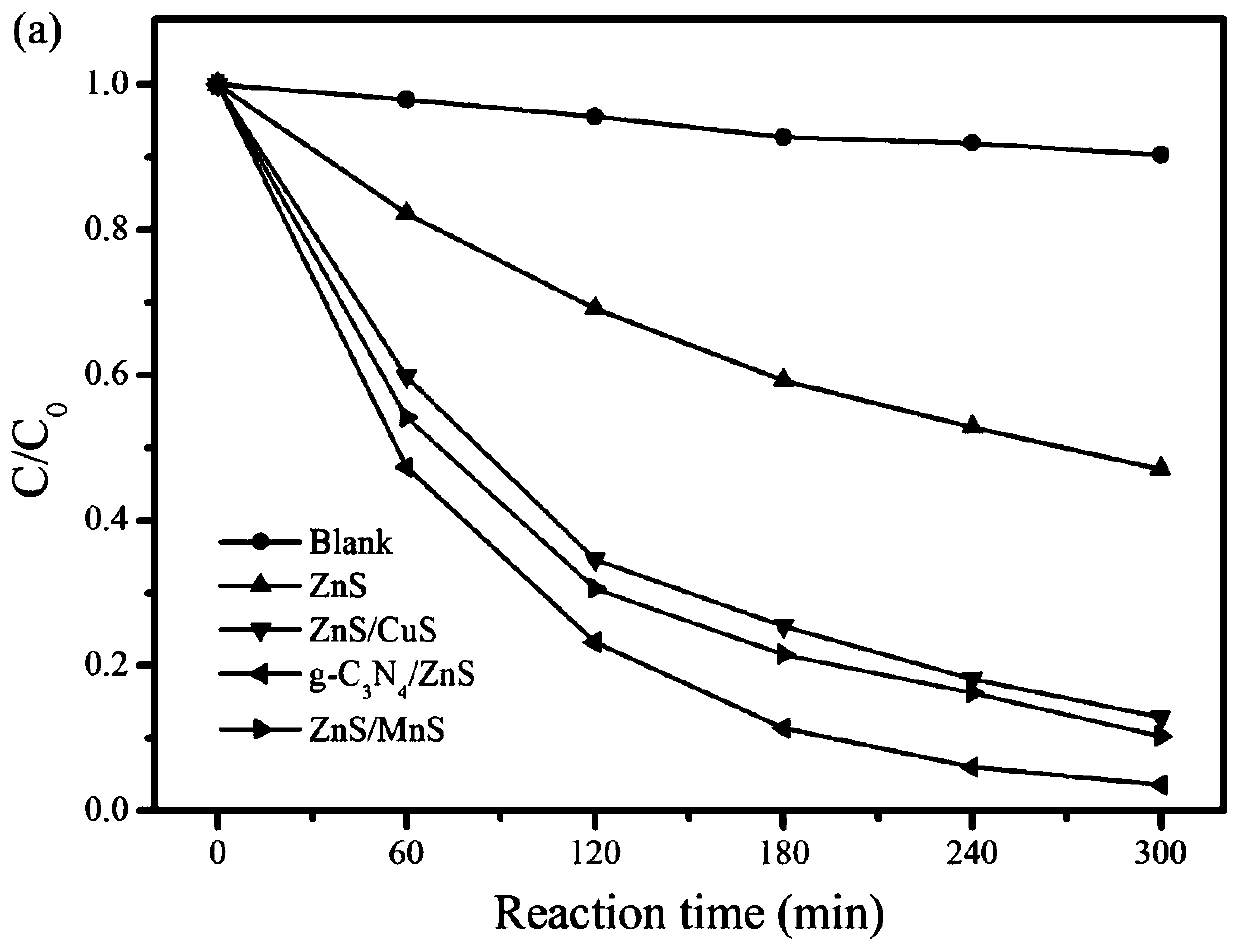

A composite material and polymer technology, applied in the field of magnetic polymer composite materials and their preparation, can solve the problems of heavy metals, insoluble instability, environmental pollution, etc., and achieve strong photocatalytic degradation of organic pollutants. Capability, wide application range, effect of widening response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a buoyant magnetic polymer composite material and its preparation method and application.

[0062] (1) ethylene glycol-water with a volume ratio of 1:1 is a reaction solvent, adding ferric chloride and hydrazine hydrate to obtain a reaction solution in which the concentration of ferric chloride is 1wt.% and the concentration of hydrazine hydrate is 0.05wt.%. React in a hydrothermal reactor at 160°C for 8 hours, centrifuge, and dry to obtain magnetic nano-iron oxides;

[0063] (2) add zinc chloride, sodium hydroxide and sodium sulfide to water, obtain zinc chloride concentration and be 0.4wt.%, the reaction solution that sodium hydroxide concentration is 30wt.% and sodium sulfide concentration is 0.4wt.%, in React at 80°C for 4 hours, centrifuge, and dry to obtain nano-zinc sulfide with photocatalytic effect;

[0064] (3) Ultrasonically disperse the magnetic nano-ferric oxide compound in a 1wt.% sodium alginate solution to obtain a reaction syst...

Embodiment 2

[0068] This embodiment provides a buoyant magnetic polymer composite material and its preparation method and application.

[0069] (1) Take ethylene glycol as reaction solvent, add iron sulfate and sodium thiosulfate, obtain the reaction solution that iron sulfate concentration is 1wt.% and sodium thiosulfate concentration is 0.5wt.%, in hydrothermal reaction kettle React at 220°C for 24 hours, centrifuge, and dry to obtain the magnetic nano-iron-sulfur compound.

[0070] (2) Take 10 g of urea and place it in a 50 mL crucible, and react in a muffle furnace at 550° C. for 5 h to obtain carbon nitride. Add zinc sulfate, carbon nitride, sodium hydroxide and thiourea to water, obtain zinc sulfate concentration and be 0.1wt.%, carbon nitride concentration is 0.05wt.%, sodium hydroxide concentration is 15wt.% and thiourea concentration is 0.2wt.% reaction solution, react at 90°C for 12h, centrifuge, and dry to obtain nano-g-C with photocatalytic effect 3 N 4 / ZnS.

[0071] (3) U...

Embodiment 3

[0075] This embodiment provides a buoyant magnetic polymer composite material and its preparation method and application.

[0076] (1) Take ethanol as the reaction solvent, add iron acetate and sodium sulfate nonahydrate, obtain the reaction solution that the concentration of iron acetate is 2wt.% and the concentration of sodium sulfate nonahydrate is 0.5wt.%, in a hydrothermal reaction kettle at 120 ℃ React for 10 hours, centrifuge and dry to obtain the magnetic nano-iron-sulfur compound.

[0077] (2) Take 10 g of urea and place it in a 50 mL crucible, and react in a muffle furnace at 500° C. for 4 h to obtain carbon nitride. Add zinc nitrate, carbon nitride, potassium hydroxide and sodium thiosulfate to water to obtain a zinc nitrate concentration of 0.1wt.%, a carbon nitride concentration of 0.025wt.%, a potassium hydroxide concentration of 12wt.% and thiosulfate The reaction solution with a sodium sulfate concentration of 0.1wt.% was reacted at 80°C for 24 hours, centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com