Grouting pipe and mold bag connecting device and machining method thereof

The technology of a connecting device and a processing method is applied in the fields of water conservancy and hydropower engineering, grouting pipe and mold bag connecting device and processing fields, which can solve the problems of cracking at the seam of the mold bag, difficulty in bearing pressure, affecting the blocking effect, etc. The ability to bear pressure, prevent the wire from slipping, and prevent the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

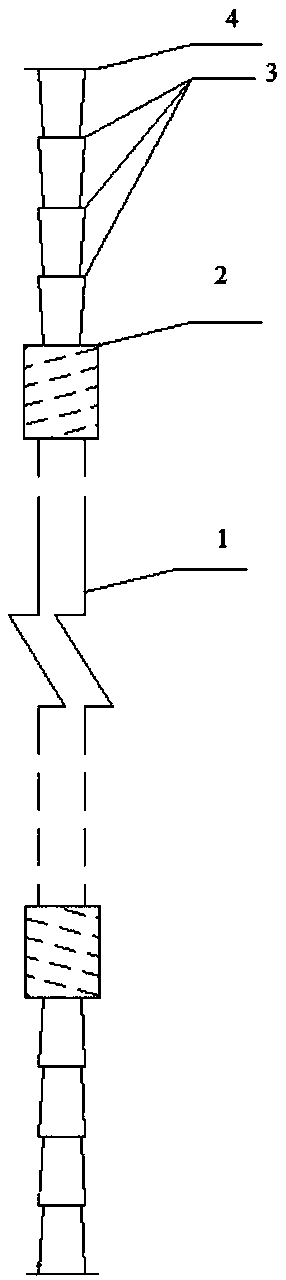

[0031] Embodiment 1: as figure 1 As shown, a connection device between a grouting pipe and a mold bag includes a mold bag and a grouting pipe. The grouting pipe includes a steel pipe body 1, a plug 2, a fish scale buckle 3, and a base 4.

[0032] The mold bag is made of metal wires and is sewn by the edge sewing method. The two ends of the steel pipe body 1 are connected with plugs 2 respectively. The end of 3 is provided with a solid base 4, and a section of fish scale button 3 includes several fish scale joints connected together. The ends of fish scale buckle 3 are bound together by iron wire. The purpose of setting the base 4 is to prevent the mold bag from falling off the grouting pipe under the external tension during the initial grouting process; : After the mold bag is filled with cement slurry, the binding positions at both ends will be subject to tension towards the center. The fish scale buckle is mainly to bind firmly against this tension. Leakage, mold bag grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com