Nano disperse dye color paste suitable for polyester printing and dyeing and preparation method thereof

A technology of nano-dispersion and dye paste, which is applied in the fields of dyeing, textiles and papermaking, etc., to achieve the effects of slowing down aggregation, improving stability, and moderate baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

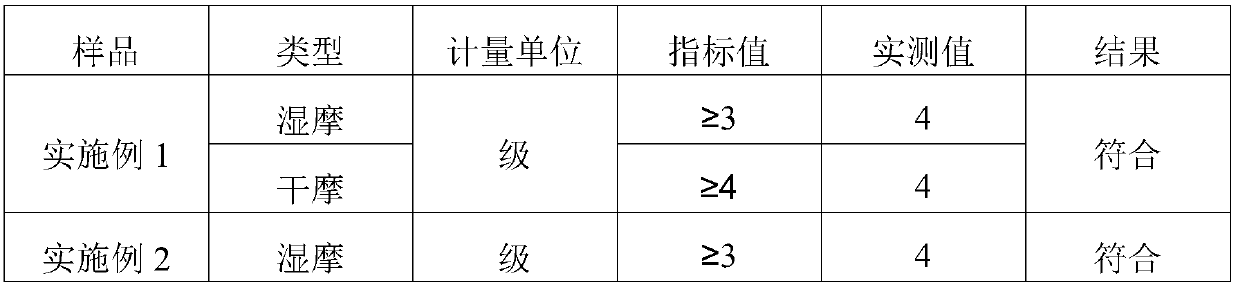

[0016] First, measure deionized water into the grinder, then add 1% Tween 80, 1% nonylphenol ethoxylate, 1% sodium lignosulfonate, 0.5% polyacrylamide and 1 % acetic acid and other auxiliary agents, finally add 5% commercial disperse dyes, control the grinding speed at 5000 rpm, and grind for 5 hours. After testing, the particle size range of the disperse dye is 100-300nm, and then the material can be discharged. This nano-color paste is used for printing and dyeing operations, and the wet and dry friction resistance of gray fabrics are tested to meet the industry requirements (see attached table).

Embodiment 2

[0018] First, add metered deionized water into the grinder, then add 1% Tween 80, 3% nonylphenol polyoxyethylene ether, 2% tannin polyacrylate, 1% polyacrylamide and Various additives such as 3% acetic acid, and finally add 10% commercial disperse dyes, control the grinding speed at 10,000 rpm, and grind for 3 hours. After testing, the particle size range of the disperse dye is 100-300nm, and then the material can be discharged. This nano-color paste is used for printing and dyeing operations, and the wet and dry friction resistance of gray fabrics are tested to meet the industry requirements (see attached table).

[0019] Attached table: Test results of color fastness to rubbing

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com