Preparation method of wear-resisting ceramic tile capable of releasing negative ion

A technology of ceramic bricks and negative ions, which is applied in the field of preparation of wear-resistant ceramic bricks, can solve problems such as inability to purify air, not conform to the development direction, and poor heat insulation effect, so as to improve human immunity, reduce red blood cell aggregation, eliminate The effect of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

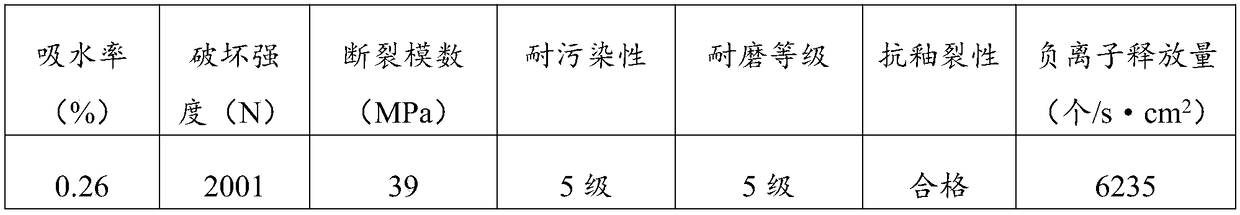

Examples

Embodiment 1

[0032] The preparation method of the wear-resistant ceramic tile capable of releasing negative ions of the present invention comprises the following steps:

[0033] Take 600kg of potassium feldspar, 1000kg of albite feldspar, 1000kg of kaolin, 1000kg of washed mud, 200kg of barium carbonate, 300kg of burnt talc, 300kg of nano-zinc oxide, 10kg of methyl cellulose, 5kg of sodium tripolyphosphate, 5kg of sodium sorbate, and negative ion powder 150kg, glaze 2000kg;

[0034]Mix the above-mentioned powders except negative ion powder and glaze, add a methylcellulose solution with a mass fraction of 0.2%, add water to make the water content of the mixed material 18%, grind for 3 hours with a ball mill, and control the speed of the ball mill 15rpm to obtain a slurry; the slurry is deironed, passed through a 200-mesh sieve, and stale for 5 hours to obtain a specific gravity of 1.60g / cm 3 , mud with a water content of 30%; the mud is sent to a spray dryer to dry and pressed to obtain a ...

Embodiment 2

[0041] The preparation method of the wear-resistant ceramic tile capable of releasing negative ions of the present invention comprises the following steps:

[0042] Take 1600kg of potassium feldspar, 2000kg of albite feldspar, 300kg of nepheline, 1700kg of kaolin, 1800kg of washed mud, 700kg of barium carbonate, 650kg of burnt talc, 700kg of nano-zinc oxide, 30kg of methylcellulose, 15kg of sodium tripolyphosphate, and 20kg of sodium benzoate , negative ion powder 250kg, glaze 2750kg;

[0043] With above-mentioned powder except negative ion powder and glaze, after mixing, add the methyl cellulose solution that mass fraction is 0.28%, add water again to make the water content of mixed material be 19%, use ball mill to grind 3.8h, ball mill speed is 17rpm, get the slurry, remove the iron from the slurry, pass through a 220 mesh sieve, stale for 6h, and get a specific gravity of 1.63g / cm 3 , a slurry with a water content of 31%; the slurry is sent to a spray dryer to dry and pre...

Embodiment 3

[0050] The preparation method of the wear-resistant ceramic tile capable of releasing negative ions of the present invention comprises the following steps:

[0051] Take 950kg of potassium feldspar, 1350kg of albite feldspar, 50kg of nepheline, 1500kg of kaolin, 1600kg of washed mud, 400kg of barium carbonate, 450kg of burnt talc, 500kg of nano-zinc oxide, 20kg of methylcellulose, 11kg of sodium tripolyphosphate, fumaric acid Dimethyl ester 12kg, negative ion powder 190kg, glaze 2250kg;

[0052] With above-mentioned powder material except negative ion powder and glaze, after mixing, add the methyl cellulose solution that mass fraction is 0.36%, add water again to make the water content of mixed material be 20%, use ball mill to grind 4.6h, and ball mill speed is 18rpm, get the slurry, remove the iron from the slurry, pass through a 240 mesh sieve, stale for 7h, and get a specific gravity of 1.64g / cm 3 , a slurry with a water content of 32%; the slurry is sent to a spray dryer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com