A kind of solid-liquid separation method of solid-containing oil product

A technology for oil and centrifugal separation, applied in chemical instruments and methods, petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of difficulty in regeneration, insufficient filtering accuracy of filter screen, adverse effects of treatment process, etc., and reduce equipment maintenance. and shutdown times, high solid-liquid separation efficiency, and long-term operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

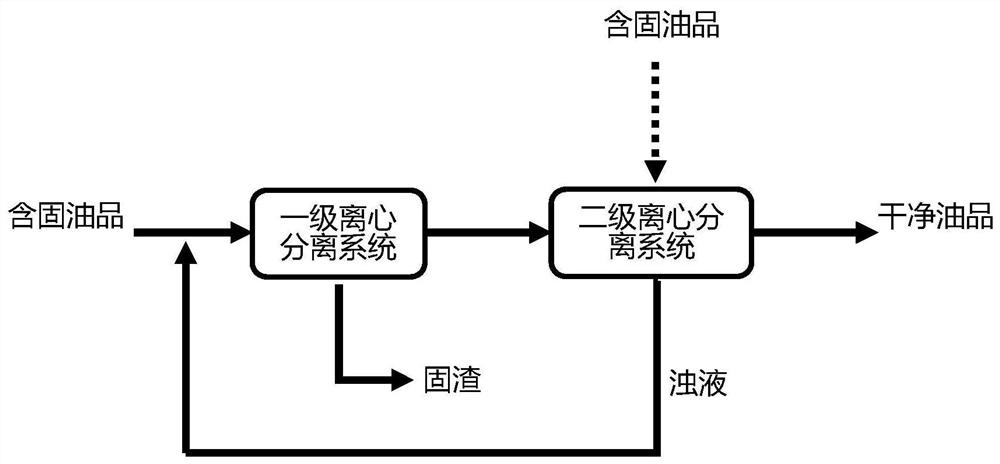

Embodiment 1

[0036] The Fischer-Tropsch slag wax (F1, melting point is 93.5 ℃, wherein the catalyst solid slag particle diameter is within the scope of 1 μm-200 μm) with a solid content rate of 10% is used as a separation raw material, and enters a horizontal screw discharge centrifuge (that is, One-stage centrifugal separation system), the feed speed is 0.7m 3 / h, the feed temperature is 170°C, the rotating speed of the horizontal screw discharge centrifuge is 5000rpm, the differential speed is 45rpm, and the centrifugation time is 50s, then the solid residue (W) and the solid residue (W) with a liquid content of 9.6wt% are obtained. Serum at a rate of 0.85 wt%. The supernatant liquid enters the disc centrifuge (i.e., the secondary centrifugal separation system), the feed temperature is 170°C, the rotating speed of the disc centrifuge is 9000rpm, and the centrifugation time is 6s to obtain a solid content rate of 8 μg / g. Clean oil (P) and turbid liquid (H2) with a solid content of 28 wt%...

Embodiment 2

[0038] The slurry of Fischer-Tropsch heavy oil (F1, melting point 38°C, catalyst solid slag particle size within the range of 1 μm-150 μm) with a solid content rate of 350 μg / g (solid content rate 3 / h, the feed temperature is 90°C, the rotating speed of the first-stage disc centrifugal separator is 9000rpm, and the centrifugation time is 8s, and the clear liquid (L1) with a solid content of 7 μg / g and the turbidity with a solid content of 30wt% are obtained. liquid (H1); clear liquid (L1) enters the second-stage disc centrifuge, the feed temperature is 80°C, the speed of the second-stage disc centrifuge is 10000rpm, and the centrifugation time is 10s, the solid content rate is 1.5 μg / g clean product (P) and turbid solution (H2) with a solid content rate of 25wt%. The turbid liquid (H1) and the turbid liquid (H2) are mixed into the horizontal screw discharge centrifuge (that is, the first-stage centrifugal separation system), the feed temperature is 90°C, and the speed of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com