Method for preparing agricultural and forestry waste hydrothermal liquefied furfural in CO2 atmosphere

A technology for agricultural and forestry waste and hydrothermal liquefaction, which is applied in the field of hydrothermal liquefaction of furfural of agricultural and forestry waste, can solve the problems of many side reactions, high cost and high energy consumption, and achieves improved selectivity, yield, stability and quality Improve and alleviate the effect of corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

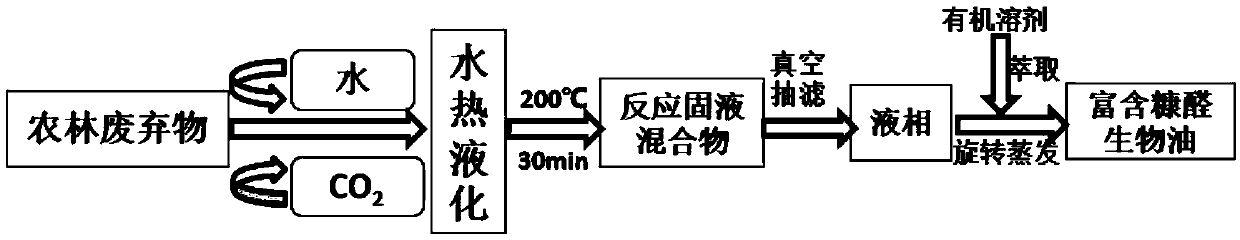

[0031] figure 1 It is a process flow diagram involved in the preparation method of hydrothermal liquefaction of furfural from agricultural and forestry waste under a CO2 atmosphere, such as figure 1 As shown, a method for preparing furfural from agricultural and forestry waste hydrothermally liquefied under a CO2 atmosphere comprises the following steps:

[0032] S1: Collect agricultural and forestry waste, crush and sieve to a particle size of 60-120 mesh, add it to a hydrothermal reactor, and mix it with deionized water to form a mixed solution with a mass-volume ratio of 1:5 to 1:15;

[0033] S2: Purge the kettle body with CO2, exhaust the air in the reactor, then close the outlet valve, fill in 0Mpa~2MpaCO2, then seal the reactor, heat it up to 150℃~250℃ under stirring, and keep it at 10~50 minute;

[0034] S3: After cooling the hydrothermal reactor to room temperature, release the pressure to collect the gas, collect the reacted solid-liquid mixture in the reactor, and ...

Embodiment 1

[0040] a CO 2 The method for preparing furfural by hydrothermal liquefaction of agricultural and forestry waste under atmosphere specifically comprises the following steps:

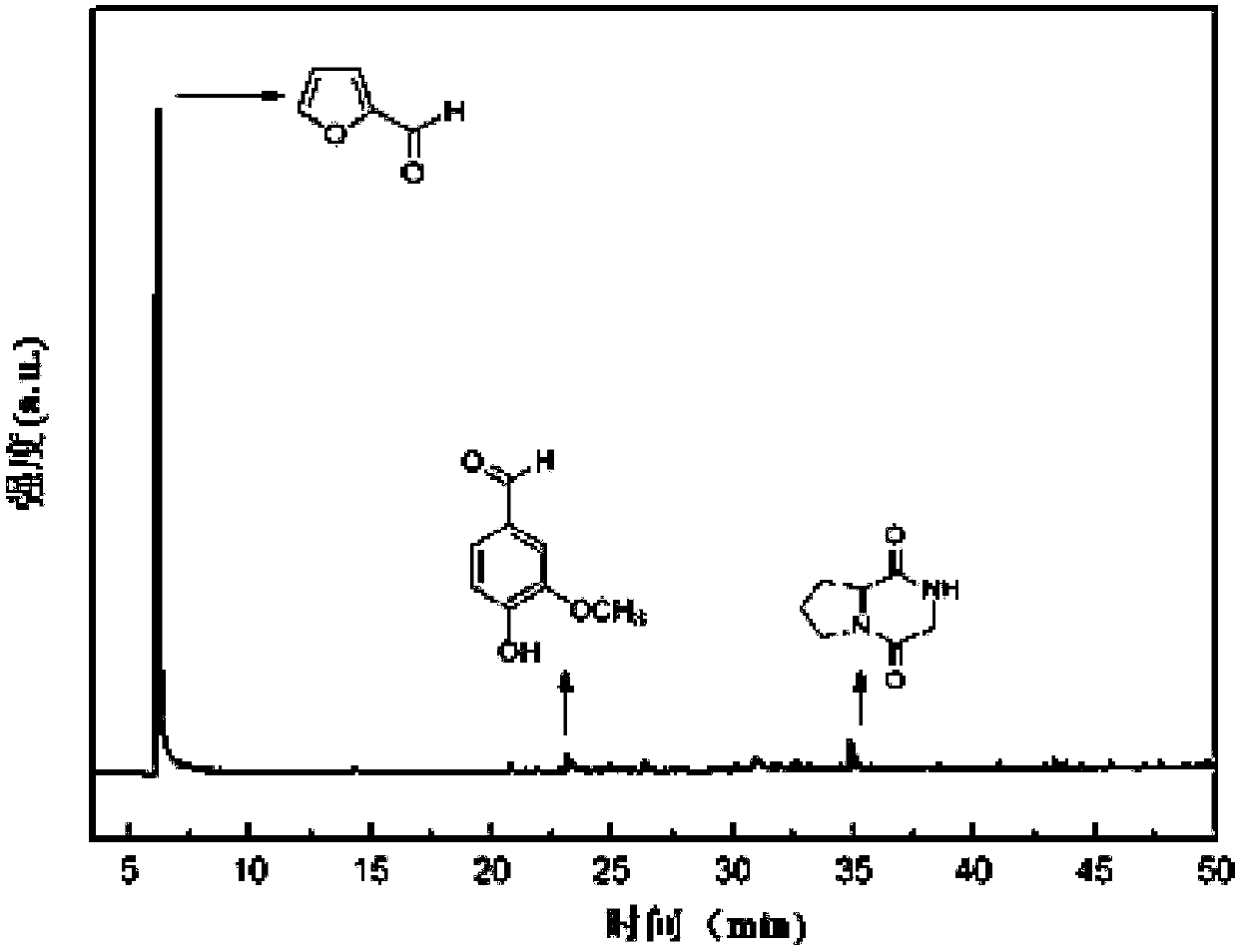

[0041] S1: Weigh 10g of rice husk and place it in a 500ml high-temperature and high-pressure hydrothermal reaction kettle, and add 100ml of deionized water;

[0042] S2: Seal the reactor, drain the air in the reactor, and fill it with CO with an initial pressure of 2Mpa 2 , turn on the heating switch, set the stirring speed to 200r / min, raise the temperature to 200°C at a rate of 8°C / min, keep it for 30min, then turn off the heating switch immediately;

[0043] S3: After the reactor is cooled to room temperature, collect the generated gas, open the reactor to take out the reaction mixture, and use CH 2 Cl 2 Clean the inner wall of the reactor and the stirrer;

[0044] S4: Using CH 2 Cl 2 The reaction mixture was extracted, CH 2 Cl 2 The extraction ratio to the reaction mixture is 1:2, the extracti...

Embodiment 2

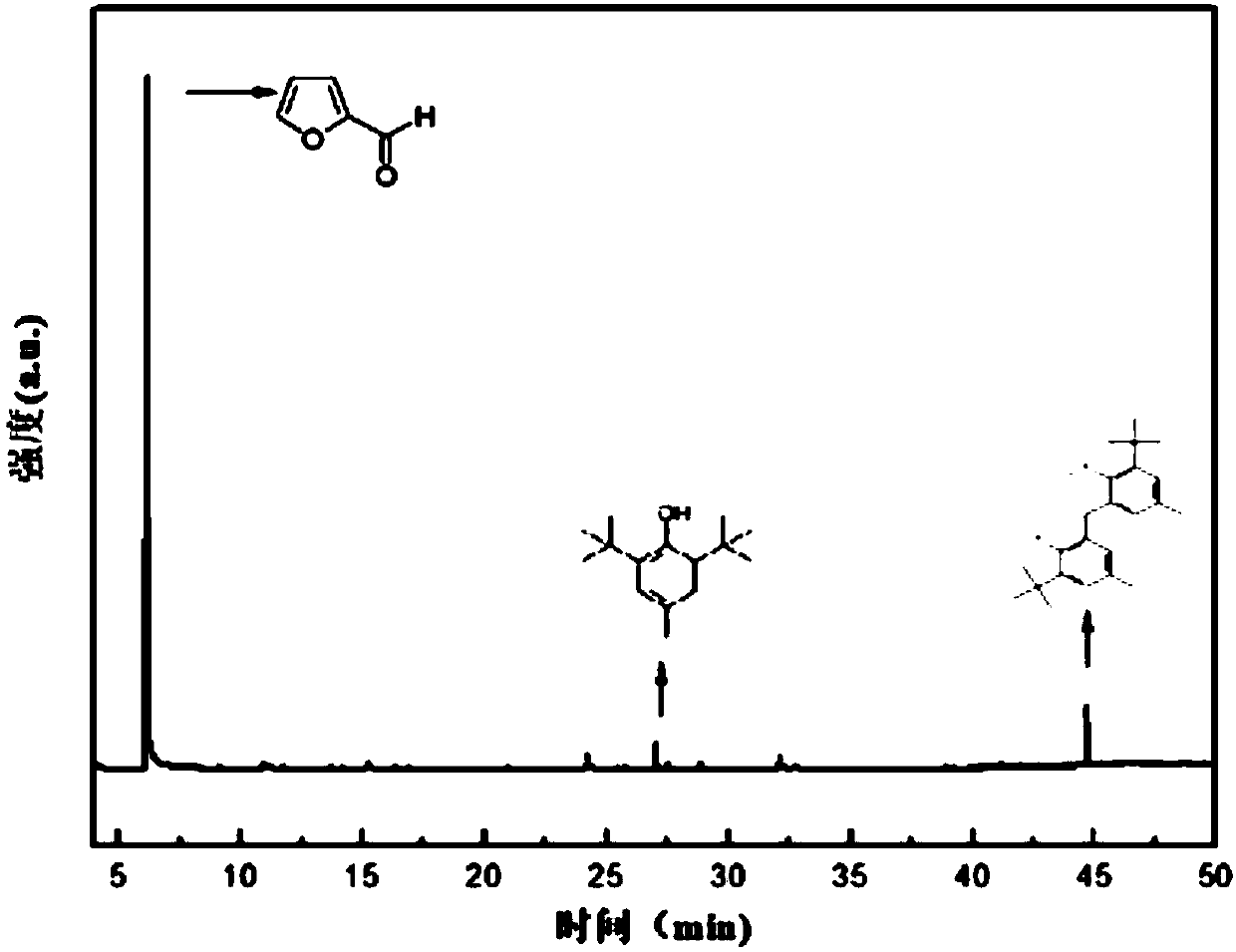

[0047] S1: Weigh 10g of corn stalks, put it in a 500ml high temperature and high pressure hydrothermal reaction kettle, and add 150ml of deionized water;

[0048] S2: Seal the reactor, drain the air in the reactor, and fill it with CO2 with an initial pressure of 1.5Mpa, turn on the heating switch, set the stirring speed to 200r / min, and raise the temperature to 200°C at a rate of about 8°C / min , after keeping for 30min, turn off the heating switch immediately;

[0049] S3: After the reaction kettle is cooled to room temperature, the generated gas is collected, the reaction kettle is opened to take out the reaction mixture, and the inner wall of the reaction kettle and the stirrer are cleaned with ether;

[0050] S4: Extract the mixture with diethyl ether, the ratio of diethyl ether to the reaction mixture is 1:2, the extraction time is 12h, filter the diethyl ether phase with a vacuum filtration device, and then recover the diethyl ether by vacuum distillation, and obtain bio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com