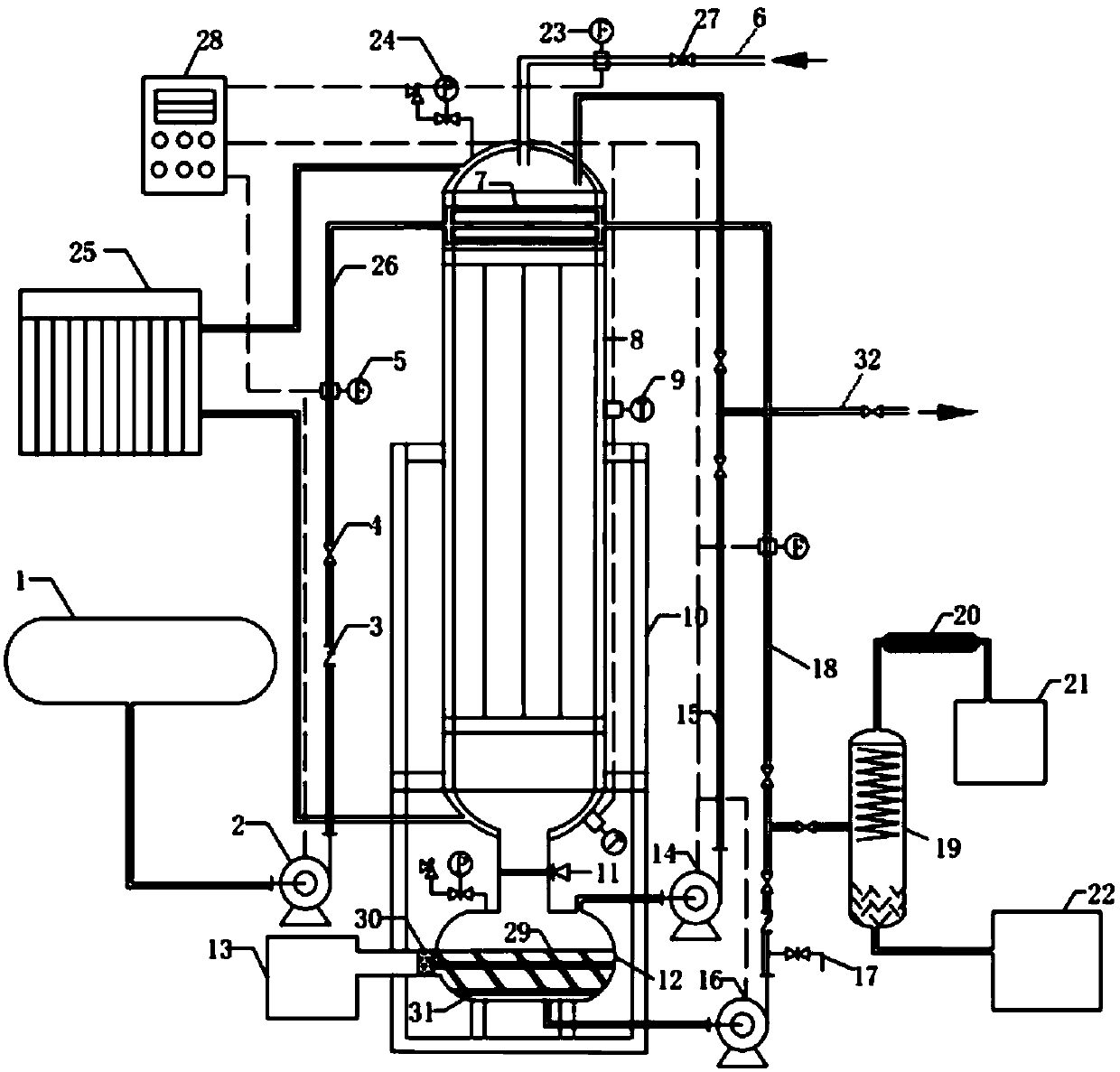

Preparation device of polysilazane and preparation method thereof

A technique for preparing polysilazane and equipment, which is applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, chemical/physical/physicochemical processes, etc., and can solve the problem of continuous production equipment that does not have a large scale , the by-product reaction rate is greatly affected, and the by-product hinders the reaction, etc., to achieve the effects of improving production efficiency, controlling the reaction rate, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

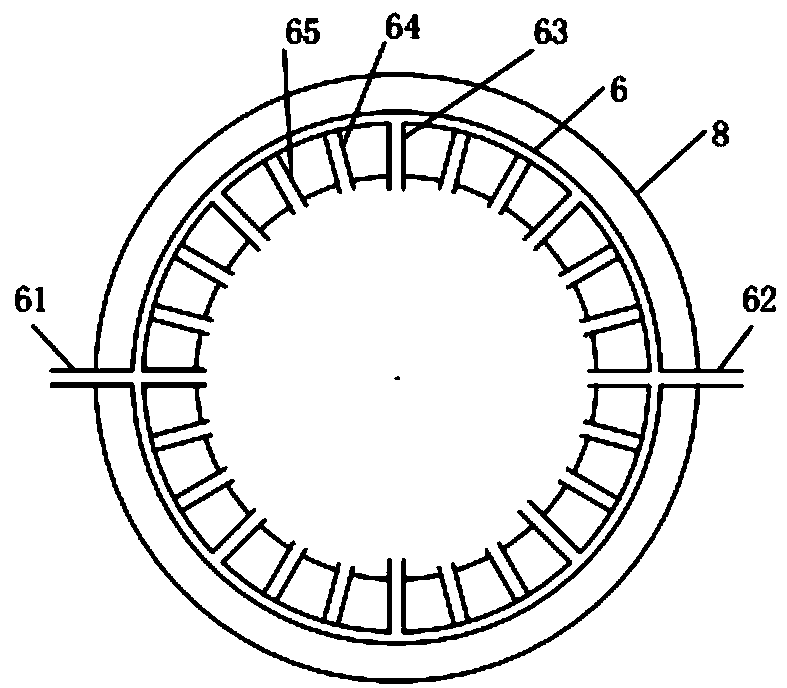

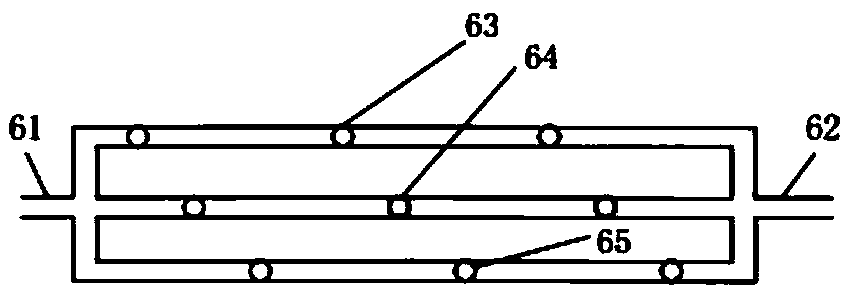

[0056] The inner diameter of the double-layer tubular reactor 8 in this embodiment is 100 mm, the outer diameter is 140 mm, and the height is 1200 mm.

[0057] A method for preparing polysilazane (with a purity of 95% and a number average molecular weight of 400) using the device of the present invention, the steps of the method are as follows:

[0058] Step S1: transporting nitrogen gas from the gas supply unit to the double-layer tubular reactor 8, purging the device, keeping the device in a nitrogen environment, and eliminating the influence of air moisture and the like;

[0059] Step S2: The cooling device 25 delivers -35°C ethylene glycol cooling liquid to the interlayer of the double-layer tubular reactor 8;

[0060] Step S3: Mix dimethyldichlorosilane and solvent n-hexane according to the volume ratio of 1:10 and add them to the raw material liquid supply device 1, and under the action of the raw material liquid delivery pump 2, transport 26 to the double In the upper ...

Embodiment 2

[0068] The inner diameter of the double-layer tubular reactor 8 in this embodiment is 100 mm, the outer diameter is 140 mm, and the height is 1200 mm.

[0069] A method for preparing polysilazane (with a purity of 98% and a number average molecular weight of 600) using the device of the present invention, the steps of the method are as follows:

[0070] Step S1: transporting nitrogen gas from the gas supply unit to the double-layer tubular reactor 8, purging the device, keeping the device in a nitrogen environment, and eliminating the influence of air moisture and the like;

[0071] Step S2: The cooling device 25 delivers -35°C cooling liquid (mixed solution of glycerol and water) to the interlayer of the double-layer tubular reactor 8;

[0072] Step S3: Mix dimethyldichlorosilane and tetrahydrofuran as a solvent according to a volume ratio of 1:20 and add them to the raw material liquid supply device 1, and transport them to the upper part of the double-layer tubular reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com