High-pressure low-sulfur-tolerant shift catalyst and preparation method thereof

A technology for changing catalysts and catalysts, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can simplify the preparation process and operation process, prevent loss, and increase the stability of activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

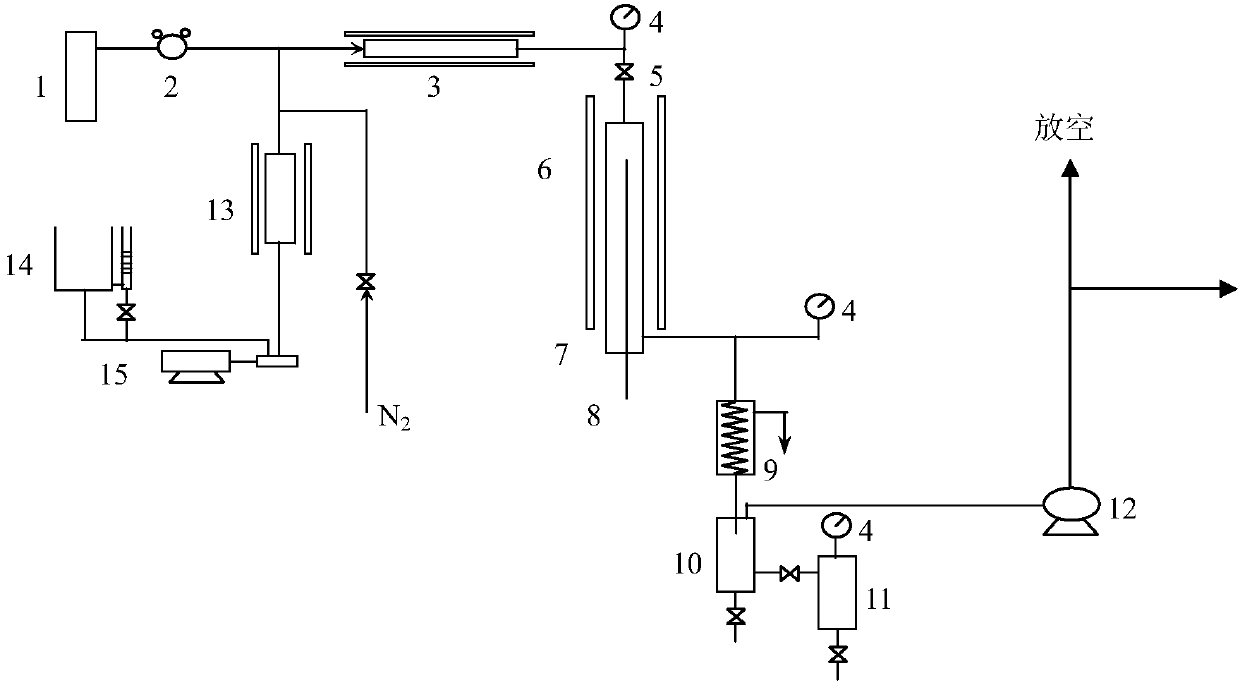

Method used

Image

Examples

Embodiment 1

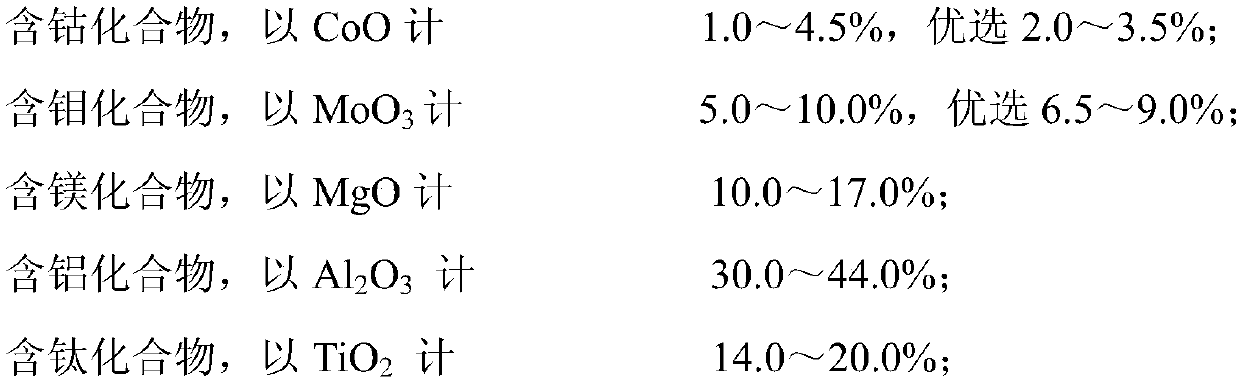

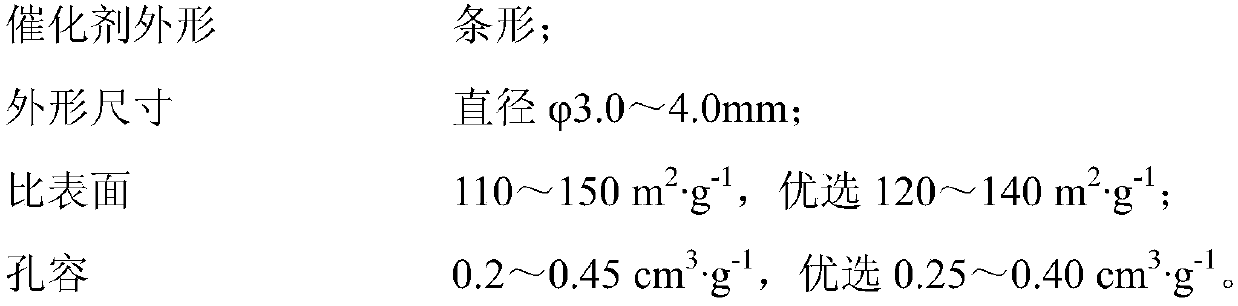

[0037] The montmorillonite was first calcined at 450°C for 5 hours, and then crushed through a 240-mesh sieve to obtain heat-treated montmorillonite. Dissolve 8.6g of ammonium molybdate with 40.0mL of deionized water to obtain molybdenum-containing solution A; dissolve 9.7g of cobalt acetate with 40.0mL of deionized water; then add 8.0g of citric acid into the above solution, stir and dissolve to obtain Cobalt-containing mixed solution B.

[0038] Weigh 34.0g montmorillonite, 12.0g magnesia, 43.6g pseudoboehmite, 17.5g metatitanic acid, 3.0g Tianqing powder and mix evenly, add solution A, knead evenly; then add solution B, knead and shape , dried naturally, baked at 550°C for 3h, and then cooled down to room temperature naturally. That is, the finished high-pressure low-sulfur resistant shift catalyst C-1 was obtained.

Embodiment 2

[0040] The montmorillonite was first roasted at 500°C for 6 hours, and then crushed through a 240-mesh sieve to obtain heat-treated montmorillonite. Dissolve 10.5g of ammonium molybdate in 40.0mL of deionized water to obtain solution A containing molybdenum; dissolve 13.6g of cobalt acetate in 40.0mL of deionized water; then add 3.0g of oxalic acid and 5g of citric acid into the above solution, and stir dissolved to obtain a cobalt-containing mixed solution B.

[0041] Weigh 14.5g montmorillonite, 15.0g magnesia, 55.0g pseudoboehmite, 25.0g metatitanic acid, 3.0g Tianqing powder and mix evenly, add solution A, knead evenly; then add solution B, knead and shape , dried naturally, baked at 550°C for 4h, and then cooled down to room temperature naturally. That is, the finished high-pressure low-sulfur resistant shift catalyst C-2 is obtained.

Embodiment 3

[0043] The montmorillonite was first calcined at 530°C for 5 hours, and then crushed through a 240-mesh sieve to obtain heat-treated montmorillonite. Dissolve 10.5g of ammonium molybdate with 40.0mL of deionized water to obtain solution A containing molybdenum; dissolve 9.7g of cobalt nitrate with 40.0mL of deionized water; then add 7.0g of citric acid into the above solution, stir and dissolve to obtain Cobalt-containing mixed solution B.

[0044] Weigh 29.0g of montmorillonite, 14.0g of magnesia, 44.3g of pseudoboehmite, 18.8g of metatitanic acid, 3.0g of Tianqing powder and mix evenly, add solution A, knead evenly; then add solution B, knead and shape , dried naturally, baked at 500°C for 2h, and then cooled down to room temperature naturally. That is, the finished high-pressure low-sulfur resistant shift catalyst C-3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com