A kind of biodegradable mesoporous nano magnetic material and preparation method thereof

A magnetic nano and inorganic nano technology, applied in biochemical equipment and methods, methods of stress stimulating microbial growth, nano-magnetism, etc., can solve the problems of high preparation conditions, uncontrollable process, difficult separation of solid and liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

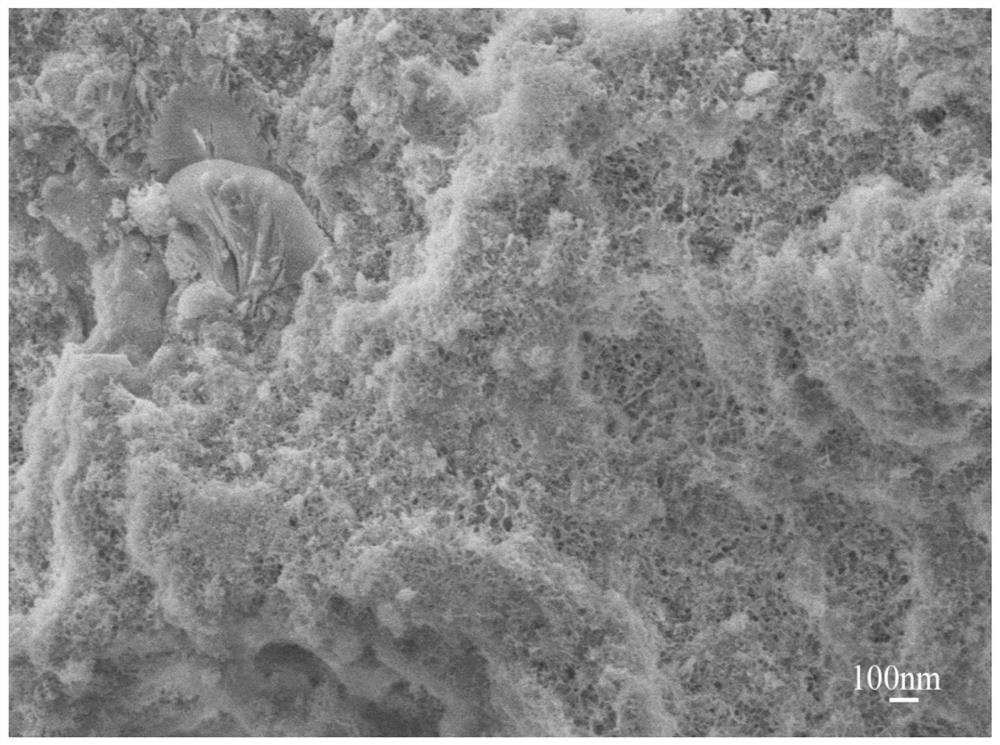

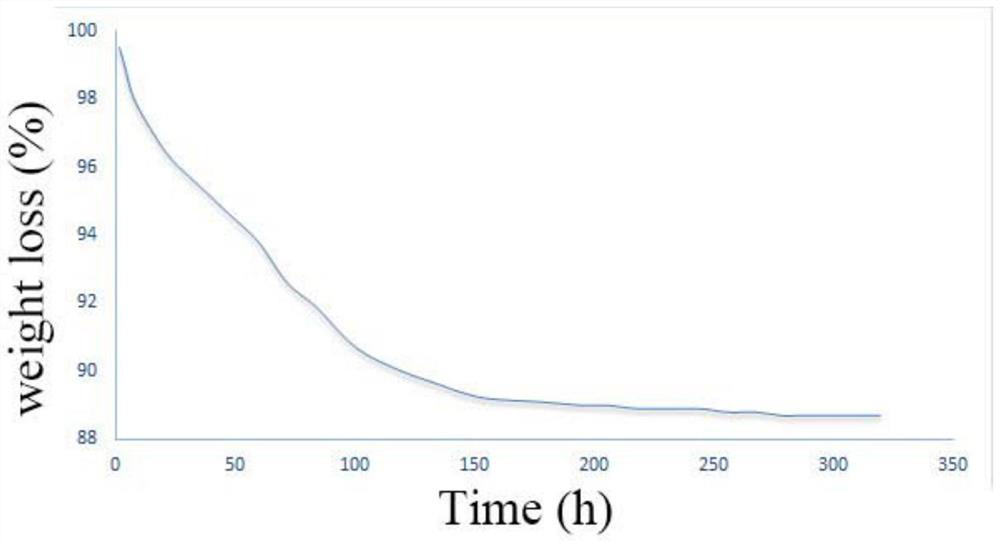

[0085] Embodiment 1, biodegradable mesoporous nano magnetic material Fe 3 o 4 Ca 4 (PO 4 ) 2 CO 3 preparation of

[0086] Weigh 12g of calcium nitrate, 5.77g of sodium monohydrogen phosphate and 1.29g of sodium carbonate, dissolve them in a hydrochloric acid solution with a pH of 1.0, and stir evenly at a constant temperature of 0°C. Add appropriate amount of FeCl 3 aqueous solution, so that the ratio of the number of molecules of calcium to iron is 4:1, continue to stir at 0°C for 30 minutes, then use sodium hydroxide solution to adjust the pH of the solution to 9.0, stir at high speed for 2 minutes, filter the product, and wash with deionized water twice. Washed twice with ethanol, dried at 50°C, and calcined at 800°C in air for 12 hours to obtain a dry product.

[0087] Take the product prepared above and place it in a citric acid-sodium hydroxide buffer solution with a pH of 5.5, stir continuously at 25°C for 30 min, centrifuge the product, remove the supernatant, w...

Embodiment 2

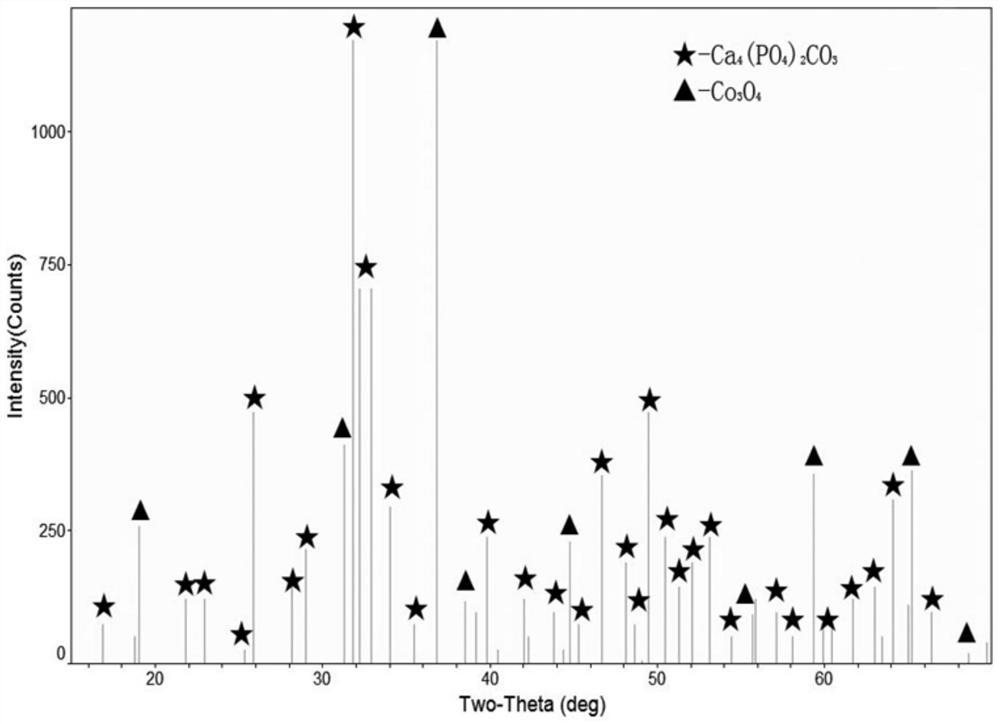

[0090] Embodiment 2, biodegradable mesoporous nano magnetic material Co 3 o 4 Ca 4 (PO 4 ) 2 CO 3 preparation of

[0091] Weigh 9g of calcium chloride, 8.24g of dipotassium hydrogen phosphate and 0.84g of sodium bicarbonate, dissolve them in a hydrochloric acid solution with a pH of 4.2, and stir evenly at a constant temperature of 25°C. Add appropriate amount of CoCl 3 aqueous solution, so that the ratio of the number of molecules of calcium to cobalt is 3:1, continue to stir at 25°C for 30min, then use potassium hydroxide solution to adjust the pH of the solution to 10.0, stir at high speed for 36h, filter the product, and wash with deionized water twice, Washed twice with ethanol, dried at 50°C, and calcined at 800°C in air for 2 hours to obtain a dry product.

[0092] The product prepared above was placed in a citric acid-sodium hydroxide buffer solution with a pH of 6.6, stirred continuously at 25°C for 6 hours, the product was centrifuged, the supernatant was remo...

Embodiment 3

[0095] Embodiment 3, biodegradable mesoporous nano magnetic material Ni 2 o 3 Ca 4 (PO 4 ) 2 CO 3 preparation of

[0096] Weigh 9g of calcium chloride, 8.24g of dipotassium hydrogen phosphate and 0.84g of sodium bicarbonate, dissolve them in a hydrochloric acid solution with a pH of 3.2, and stir evenly at a constant temperature of 100°C. Add appropriate amount of NiCl 2 Aqueous solution, so that the ratio of calcium to nickel molecules is 4:1, continue to stir at 100°C for 30 minutes, then use potassium hydroxide solution to adjust the pH of the solution above 11.0, stir at high speed for 2 hours, filter the product, and wash with deionized water twice , washed twice with ethanol, dried at 50°C, and calcined at 800°C in air for 6 hours to obtain a dry product.

[0097] Take the product prepared above and place it in a citric acid-sodium hydroxide buffer solution with a pH of 6.0, stir continuously at 25°C for 6 hours, centrifuge the product, remove the supernatant, was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com