Preparing method for coarse rice powder special for baking

A technology of brown rice flour and brown rice, which is applied in the field of preparation of brown rice flour for baking, can solve the problems of inability to change the high-temperature processing temperature adaptability of brown rice flour, loss of natural green color and rice flavor of brown rice flour, microwave technology can only partially ripen, etc. Achieve the effects of improving sensory performance and flavor, promoting human health and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

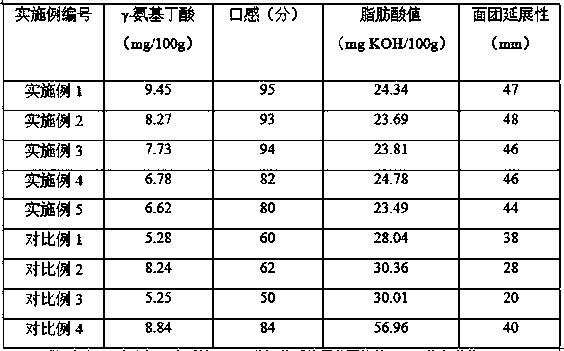

Examples

Embodiment 1

[0038] (1) After selecting the full-grained rice harvested that year, after dehulling, pick out the unpolished and mold-free brown rice grains, which are sterilized and cleaned by ozone and sent to the germination machine equipped with nozzles. Under humidified conditions (humidity is 80%) Pass the food grade cellulase solution (acetic acid buffer solution, pH 5.0) equivalent to 0.7 times the weight of the brown rice particles after ozone sterilization and cleaning with a concentration of 0.01 mg / ml, and carry out micro-germination for 12 hours at a germination temperature of 37°C. The time bud length is 0.4mm;

[0039] (2) Treat the resulting brown rice with superheated steam at a temperature of 150°C for 2 minutes, cool to 42°C for 10 minutes, and then add a food-grade transglutaminase solution (acetic acid buffer) equivalent to twice the weight of the brown rice after the superheated steam treatment. Solution, pH 6.0) The concentration is 0.002mg / ml, after soaking for 20 minut...

Embodiment 2

[0043] (1) After selecting the full-grained rice harvested that year, after dehulling, pick out the unpolished and mold-free brown rice grains, which are sterilized and cleaned by ozone and sent to the germination machine equipped with nozzles. Under humidified conditions (humidity is 70%) Pass the food grade cellulase solution (acetic acid buffer solution, pH 5.0) 0.8 times the weight of the brown rice grains after ozone sterilization and cleaning with a concentration of 0.01 mg / ml, and carry out micro-germination for 10 hours at a germination temperature of 37°C. The time bud length is 0.4mm;

[0044] (2) Treat the resulting brown rice with superheated steam at a temperature of 120°C for 3 minutes, cool to 43°C for 10 minutes, and then add a food-grade transglutaminase solution (acetic acid buffer) equivalent to twice the weight of the brown rice after the superheated steam treatment. Solution, pH 6.0) The concentration is 0.002mg / ml, after soaking for 25 minutes, drain the wat...

Embodiment 3

[0048] (1) After selecting the full-grained rice harvested that year, after dehulling, pick out the unpolished and mold-free brown rice grains, which are sterilized and cleaned by ozone and sent to the germination machine equipped with nozzles. Under humidified conditions (humidity is 70%) Pass the food grade cellulase solution (acetic acid buffer solution, pH 5.0) equivalent to 0.9 times the weight of the brown rice grains after ozone sterilization and cleaning with a concentration of 0.01 mg / ml, and perform micro-germination for 8 hours at a germination temperature of 37°C. At this time, the sprout length is 0.3mm; (2) Treat the resulting brown rice with superheated steam at a temperature of 130°C for 3 minutes, cool to 44°C for 10 minutes, and then add food grade equivalent to twice the weight of the brown rice after the superheated steam treatment The concentration of the transglutaminase solution (acetic acid buffer solution, pH 6.0) is 0.002mg / ml after soaking for 18 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com