Device and method for detecting thermal barrier coating (TBC) surfaces based on area array pulse laser excitation

A pulsed laser, layered technology, applied in measurement devices, material defect testing, instruments, etc., can solve the problems of high power density, easily damaged material surface, unsuitable for thermal excitation source of infrared thermal wave nondestructive testing technology, etc., and achieve precise positioning. The effect of shooting, low price, easy operation and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

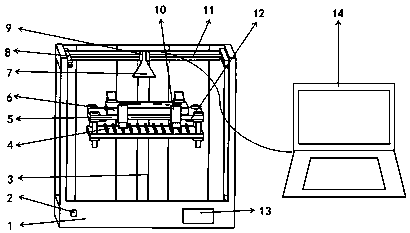

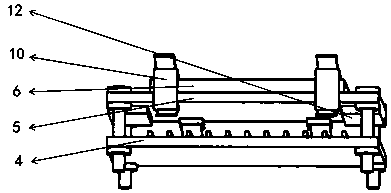

[0021] Such as figure 1 As shown, the area array pulsed laser 4 is a semiconductor-pumped solid-state laser with a maximum power of 100W, a spot diameter of 5mm, a pulse width of 1ms~5s, and a wavelength of 1064nm. The horizontal distance between two adjacent laser light sources of the area array photoelectric sensor is 20mm~25mm, the vertical distance is 20mm~25mm. Infrared thermal imager 7 is an uncooled thermal imager, which can be used immediately when it is turned on, and does not need to be cooled by a refrigerator. The image size is not less than 160×120 pixels, and the response band is 8 mu m~14 mu m, the acquisition frame frequency is 50Hz, the thermal sensitivity is 50mK, the acquisition time is 10s, and the scanning time of area array pulsed laser 4 is 6s. The diameter of the screw rod 3 is 8mm, the lead is 1mm, the precision can generally reach 0.1mm, and the speed is controlled between 2m / s~10m / s. The movement of the longitudinal slide rail 8 and the transvers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com