A Method for Reducing the Depth of Coarse Grain Layer on the Surface of Aluminum Alloy Hot Forging

A technology of hot forging and layer depth, applied in the field of metal forging and forming, can solve the problems of inability of the depth of the coarse-grained layer and waste of hot forgings of materials, and achieve the effect of reducing the depth of the coarse-grained layer of the surface layer, reducing the waste of materials, and improving the qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

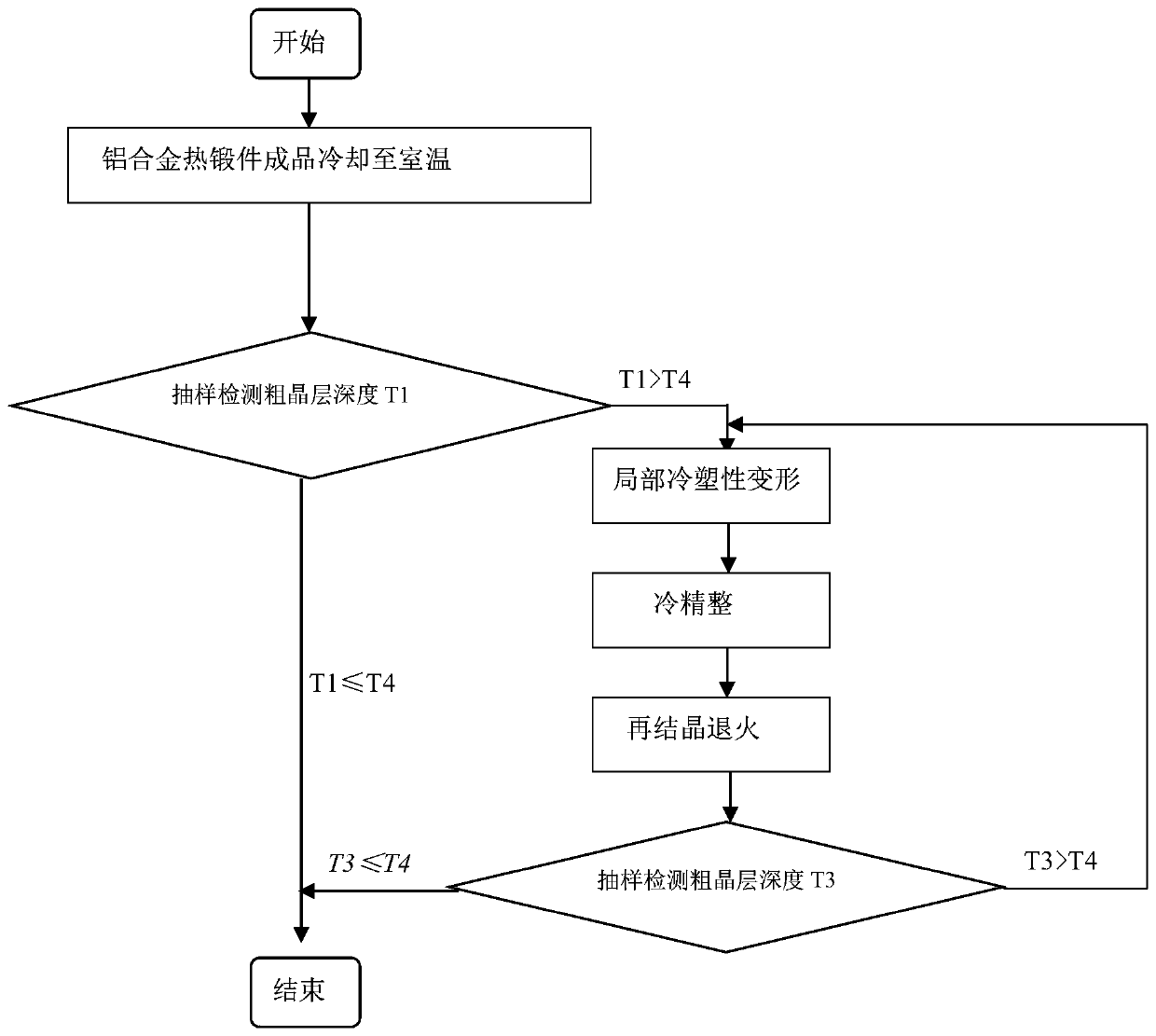

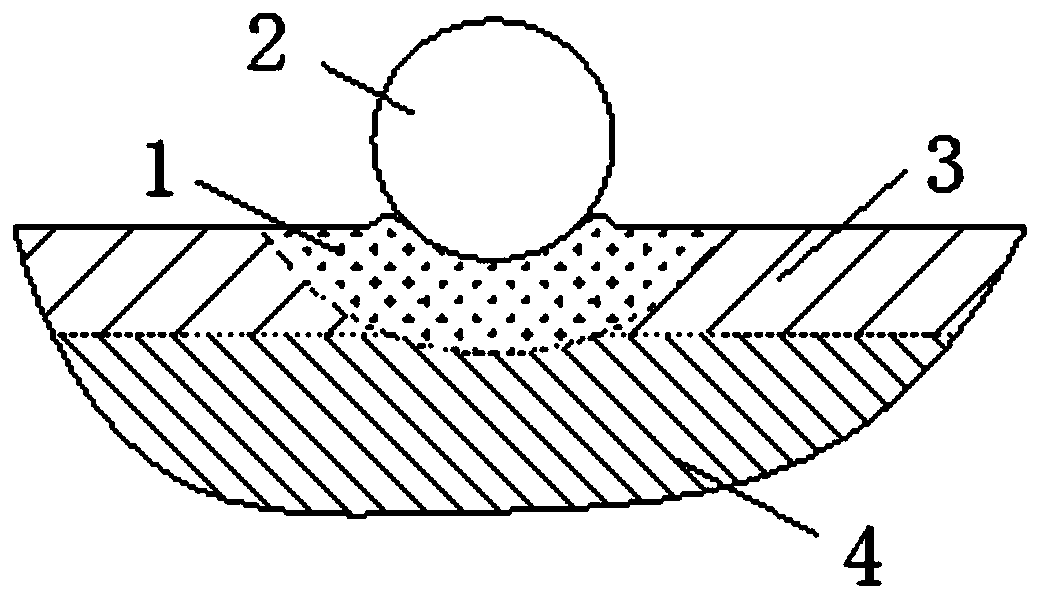

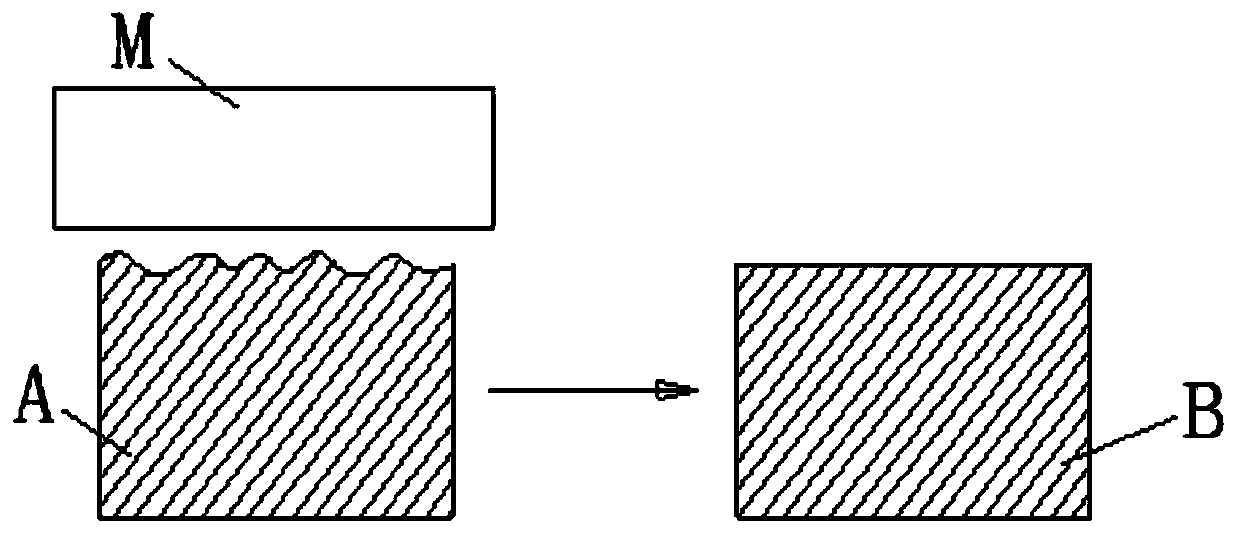

[0030]After the conventional aluminum alloy hot forging process, the present invention adds the local cold plastic deformation and cold finishing process of the surface metal, the cold plastic deformation makes the coarse-grained layer obtain sufficient deformation, and the recrystallization annealing makes the grains of the coarse-grained layer Refinement, so the effect of reducing the depth of the coarse grain layer on the surface of aluminum alloy hot forgings can be achieved without removing materials, reducing material waste and scrapping of hot forgings caused by coarse grain defects, and improving the pass rate of aluminum alloy hot forgings. It can be used for batch repair of the whole batch of coarse-grain defect products, and it can also be used for targeted repair of small batches of coarse-grain defect products. The specific process is as follows:

[0031] (S1) Cool the same batch of aluminum alloy hot forgings that have been produced and meet the pre-designed shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com