A method for preparing high-brightness iron red hybrid pigments by using oil shale semi-coke

An oil shale semi-coke and pigment technology, which is applied in the field of nano-inorganic pigment preparation, can solve the problems of affecting the color performance of the pigment, the size of the powder particles is large, and the introduction of other impurities, etc., and achieves bright color, low synthesis temperature, and reduced preparation temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

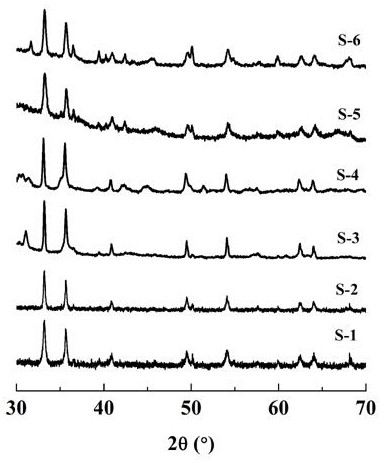

[0029] Take 0.35 g of semi-coke, 0.381 g of ferric chloride, 0.375 g of aluminum nitrate, and 0.12 g of sodium hydroxide, mix them and put them into an 80mL zirconia grinding jar, add 37g of zirconia balls with a diameter of 2mm, and the ball-to-material ratio is 30; placed in a mill, and ground at 500rpm for 60 minutes to obtain a precursor; calcined the precursor at 700°C for 60 minutes to obtain an iron red hybrid pigment, marked as S-1, which L * , a * , b * See Table 1 for color parameters.

Embodiment 2

[0031] Take 0.25 g of semi-coke, 0.72 g of ferric nitrate, 0.133 g of aluminum chloride, and 0.424 g of sodium carbonate, mix them and put them into a 80 mL zirconia grinding tank, add 31 g of zirconia balls with a diameter of 2 mm, the ball-to-material ratio 20, placed in a mill, and ground at 700 rpm for 30 min to obtain a precursor; the precursor was calcined at 800°C for 30 min to obtain an iron red hybrid pigment. marked S-2, its L * , a * , b * See Table 1 for color parameters.

Embodiment 3

[0033] Take 0.25 g of semi-coke, 0.254 g of ferric chloride, 0.360 g of ferrous nitrate, 0.258 g of potassium aluminum sulfate and 0.250 g of potassium hydroxide, mix them into a 80 mL zirconia grinding jar, add 48 g of 2 mm in diameter Zirconium dioxide balls with a ball-to-material ratio of 35; placed in a mill and ground at 500 rpm for 240 min to obtain a precursor; calcined the precursor at 500°C for 90 min to obtain an iron red hybrid pigment, marked as S -3, its L * , a * , b * See Table 1 for color parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com