Iron box for chemical waste carrying and application method for iron box

A waste and chemical technology, which is applied in the field of iron boxes for chemical waste handling, can solve the problems of time-consuming and laborious handling of plastic barrels, poor environmental protection, and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

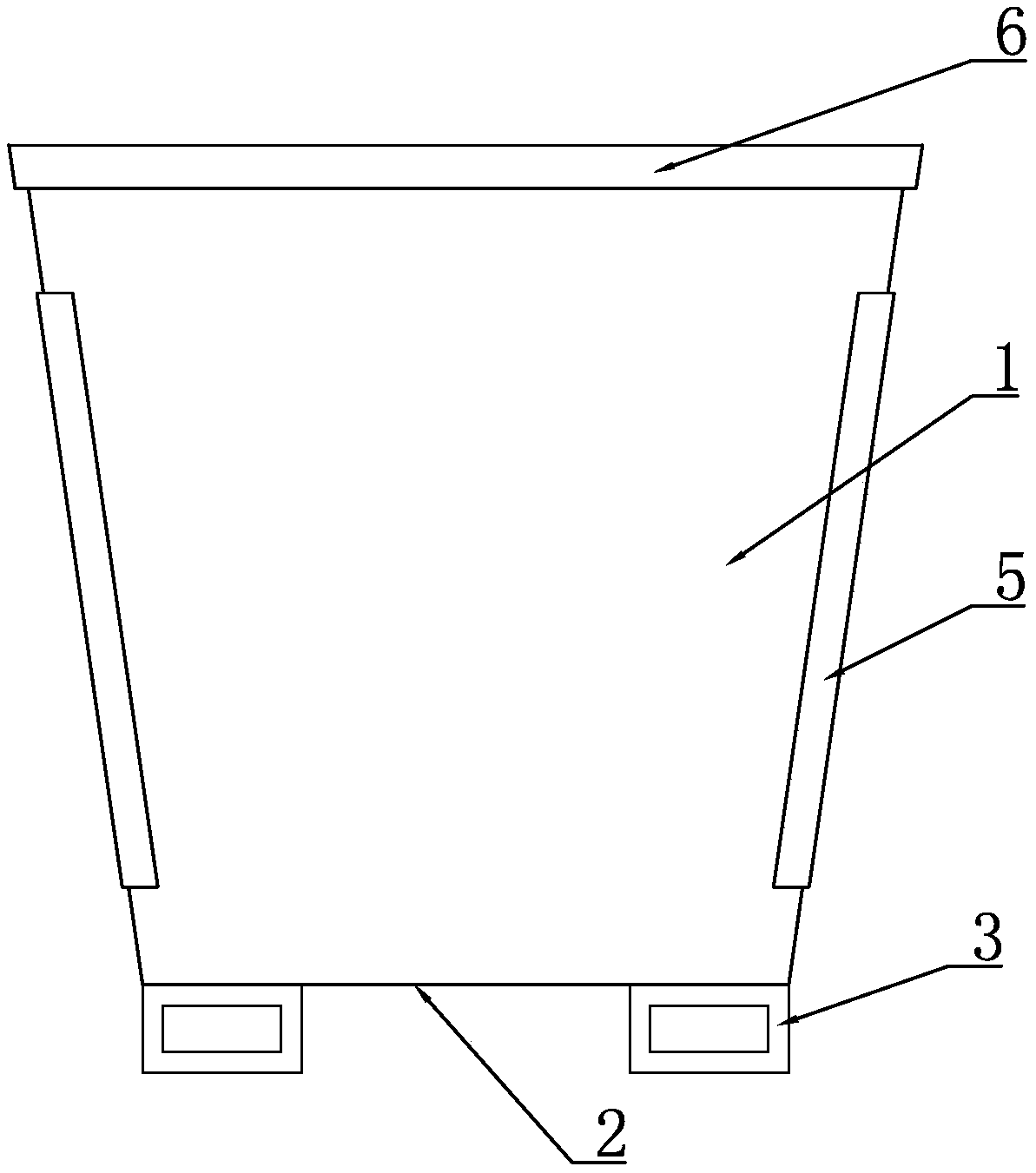

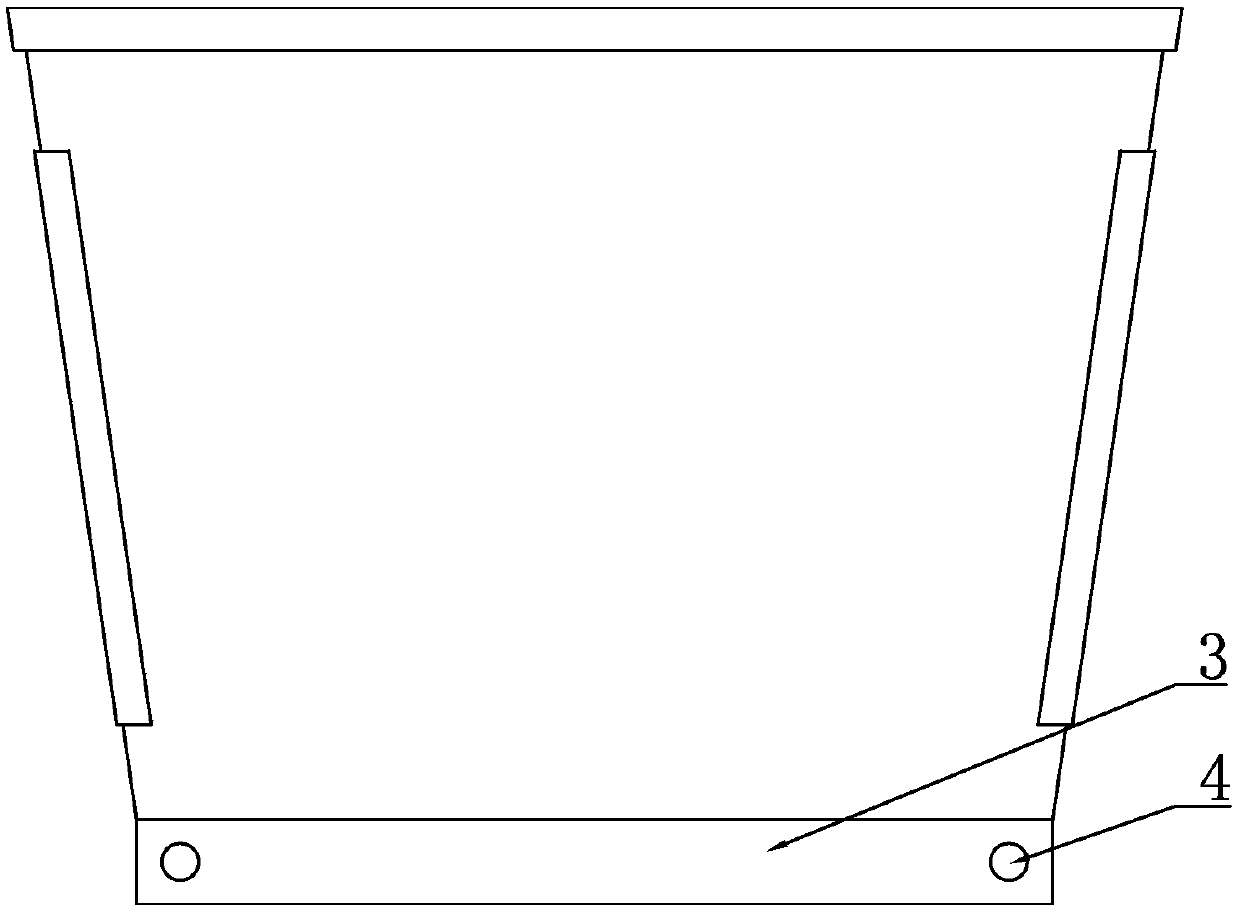

[0016] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-2 :

[0017] An iron box for transporting chemical waste, characterized in that it includes a box structure surrounded by a plurality of side panels 1, a bottom plate 2 is provided at the bottom of the box, the top of the box is an open end, and two supply rails are provided at the bottom of the bottom plate 2. The forklift foot 3 used by the forklift truck is a metal square tube welded to the bottom of the base plate 2, so that the front fork of the forklift can be directly inserted into the forklift foot 3 to carry the iron box, saving time and effort.

[0018] Both ends of the metal square tube are provided with through holes 4 radially penetrating, and the through holes 4 are convenient for the crane to lift one side of the iron box to realize its rollover.

[0019] The adjacent side plates 1 and between the side plates 1 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com