Cationic resin catalyst, preparation method thereof and catalytic application thereof in preparation of glycolic acid by methyl glycolate hydrolysis method

A technology of cationic resin and methyl glycolate, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of increased separation cost and conversion of methyl glycolate Low efficiency and other problems, to achieve the effect of increasing conversion rate, promoting complete hydrolysis, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

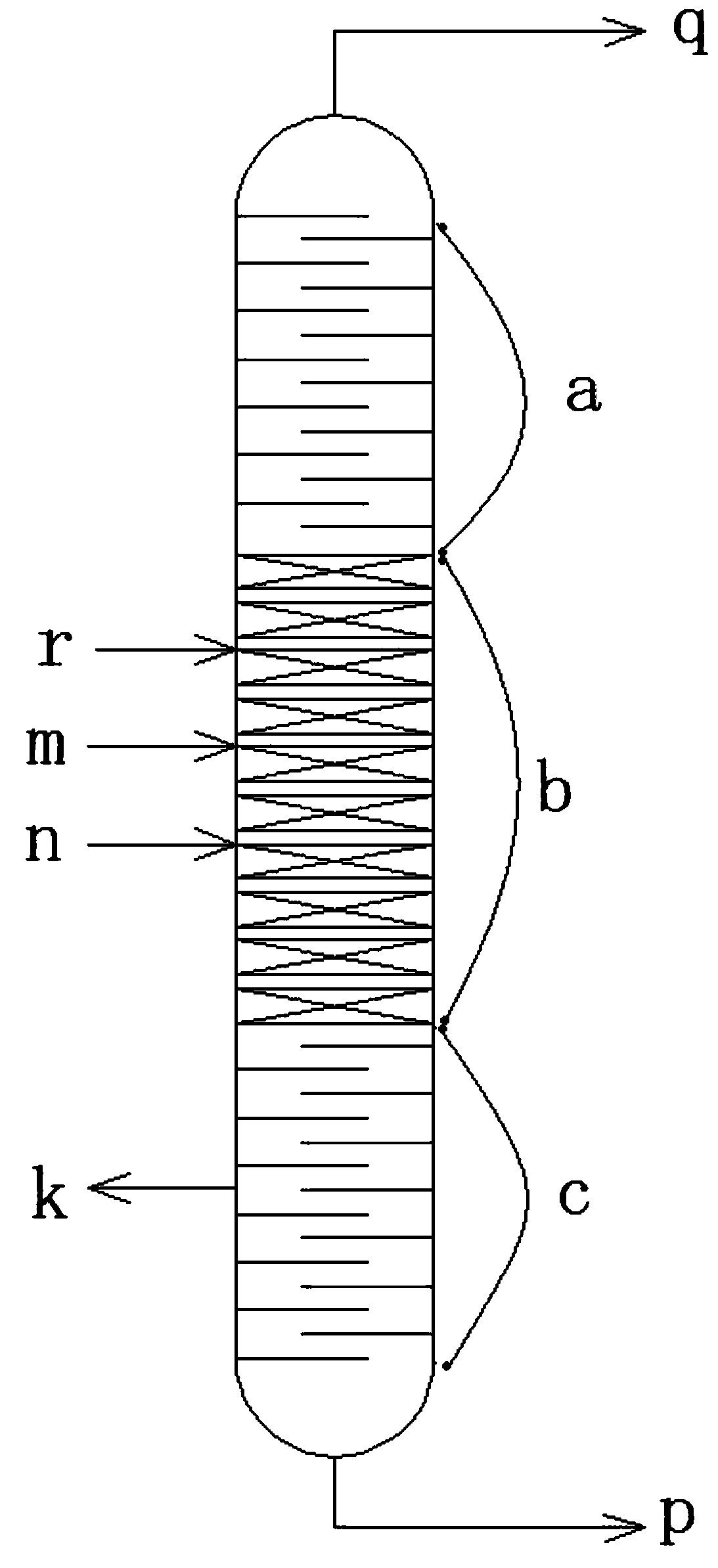

Image

Examples

Embodiment 1

[0019] Example 1 Catalyst A

[0020] Suspension copolymerization system: mix 100g of styrene with 7g of divinylbenzene, wash twice with NaOH solution with a concentration of 1mol / l, and then wash twice with water to remove the polymerization inhibitor in the raw material; the porogen is cyclohexane, Initiator is cumene hydroperoxide, is 1:0.1:0.005 with the mass ratio of styrene and porogen, initiator, adds porogen and initiator in the mixture of styrene and divinylbenzene, waits After the initiator is dissolved, the whole is poured into a stirred tank that has been equipped with a dispersant of a 0.5% polyvinyl alcohol aqueous solution. The quality of the polyvinyl alcohol aqueous solution is the total mass of styrene, divinylbenzene, porogen and initiator. 3 times;

[0021] Copolymerization reaction: the rotation speed is 80r / min, first raise the temperature to 60°C, hold for 2h, then raise the temperature to 70°C, hold for 3h, finally raise the temperature to 90°C, hold fo...

Embodiment 2

[0024] Example 2 Catalyst B

[0025] Suspension copolymerization system: mix 100g of styrene with 7g of divinylbenzene, wash twice with NaOH solution with a concentration of 1mol / l, and then wash twice with water to remove the polymerization inhibitor in the raw material; the porogen is benzene, the initiator Be azobisisoheptanonitrile, the mass ratio of styrene and porogen, initiator is 1:0.1:0.005, add porogen and initiator in the mixture of styrene and divinylbenzene, treat initiator After dissolving, the whole is poured into a stirred tank with a concentration of 1.0% methylcellulose aqueous solution dispersant, the quality of methylcellulose aqueous solution is the total mass of styrene, divinylbenzene, porogen and initiator 4 times;

[0026] Copolymerization reaction: the rotation speed is 120r / min, first raise the temperature to 60°C, hold for 4h, then raise the temperature to 70°C, hold for 6h, finally raise the temperature to 90°C, hold for 1h, then cool and filter t...

Embodiment 3

[0029] Example 3 Catalyst C

[0030] Suspension copolymerization system: mix 100g of styrene with 7g of divinylbenzene, wash twice with NaOH solution with a concentration of 1mol / l, and then wash twice with water to remove the polymerization inhibitor in the raw material; the porogen is benzene, the initiator For benzoyl peroxide, the mass ratio of styrene to porogen and initiator is 1:0.05:0.02, add porogen and initiator to the mixture of styrene and divinylbenzene, and wait for the initiator to dissolve Finally, the whole is poured into the stirred tank that has been equipped with the dispersant of 0.5% sodium dodecylbenzenesulfonate aqueous solution, the quality of sodium dodecylbenzenesulfonate aqueous solution is styrene, divinylbenzene, 3 times the total mass of porogen and initiator;

[0031] Copolymerization reaction: the rotation speed is 80r / min, first raise the temperature to 60°C, hold for 2h, then raise the temperature to 70°C, hold for 3h, finally raise the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com