Preparation method of bulk cobalt-molybdenum hydrodesulfurization catalyst

A hydrodesulfurization and catalyst technology, applied in the petrochemical field, can solve the problems of large toxic substances, raw material toxicity, and no close contact, and achieve high hydrodesulfurization activity, improved catalytic activity, and close contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Synthesis of precursors

[0028] Dissolve 3.1g of ammonium molybdate in 250ml of water, then add 7.3g of cobalt nitrate, heat, stir and reflux to dissolve; add phosphorous acid to adjust the pH of the system to 4.0, then heat the solution to 60°C and maintain it for 72h to obtain cobalt-molybdenum bimetallic - Oxygen cluster powder crystals;

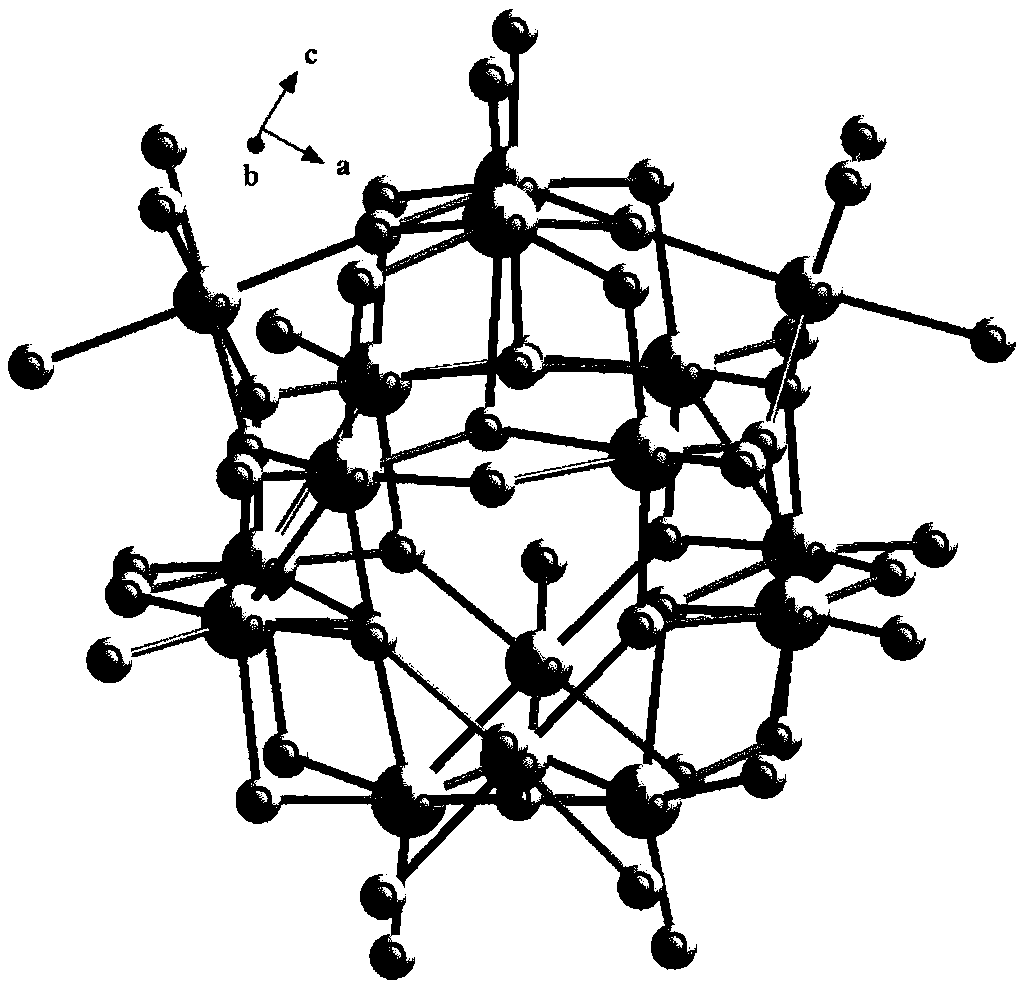

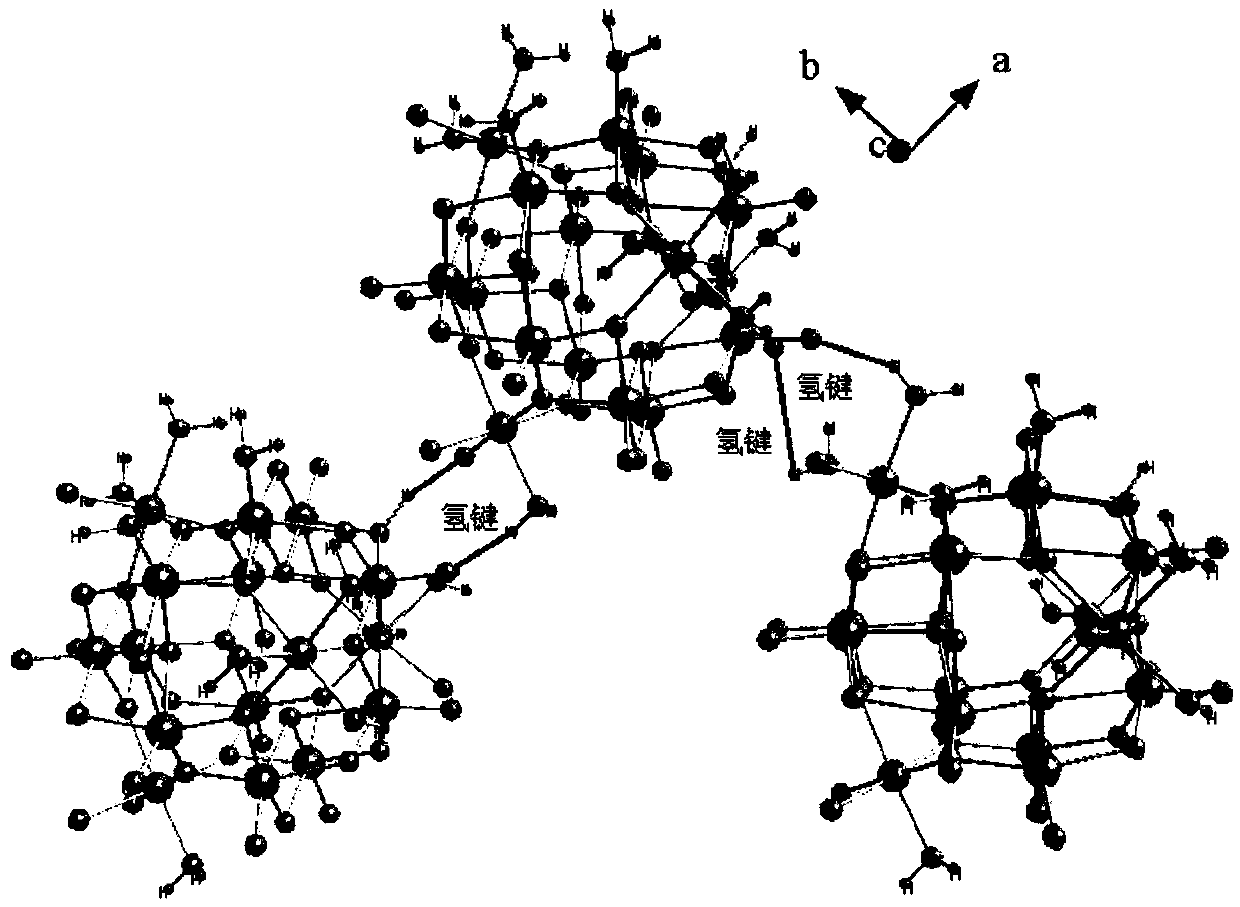

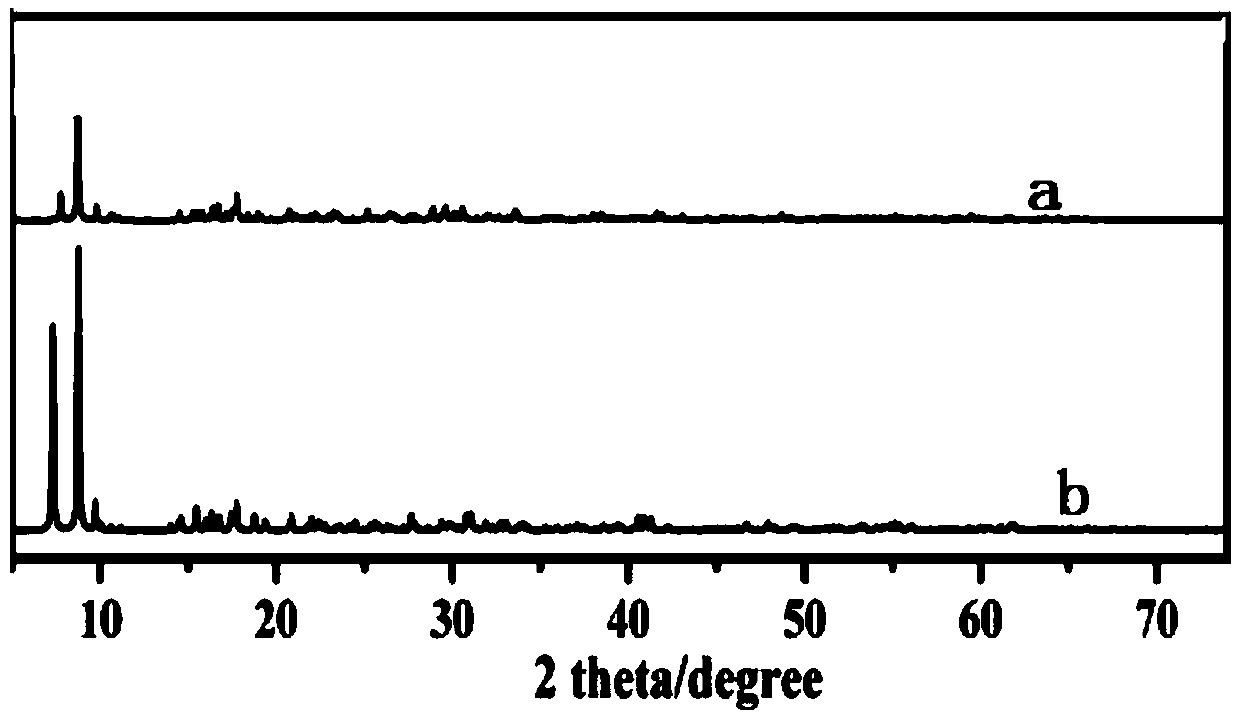

[0029] figure 1 The spatial structure diagram of the cobalt-molybdenum double metal-oxygen cluster obtained in this example shows that the metal-oxygen cluster is a four-capped Keggin structure, and the cobalt-molybdenum atoms are connected by bridge oxygen bonds Mo-O-Co, and the bond length is about And the cobalt atom is located outside the molybdenum atom cluster, which belongs to the close contact in the true sense, which is conducive to the formation of the active phase; in addition, the cobalt molybdenum atom is more suitable, the cluster volume and the cluster-cluster distance are moderate, and it is suitable as the p...

Embodiment 2

[0042] The preparation process of the catalyst was the same as in Example 1, except that hydrazine sulfate was added during the preparation of the catalyst precursor, and the pH of the solution was adjusted to 5.0. Present embodiment catalyst preparation method is as follows:

[0043] (1) Precursor synthesis

[0044] Dissolve 3.1g of ammonium molybdate in 250ml of water, add 7.3g of cobalt nitrate, heat and stir to reflux to dissolve; add acetic acid to adjust the pH of the system to 5.0, then add 0.7g of hydrazine sulfate, heat the solution to 60°C and maintain it for 72h to obtain Cobalt-molybdenum bimetallic-oxygen cluster powder crystal;

[0045] (2) Mix aluminum hydroxide dry rubber powder and water at a mass ratio of 1:10 to form a slurry at 70°C; then slowly add nitric acid at an acid-to-gel ratio of 1:10 and stir for 30 minutes; then add the cobalt obtained in step (1) Molybdenum bimetallic-oxygen clusters were mixed evenly and extruded into strips; after forming, th...

Embodiment 3

[0052] The catalyst preparation process is the same as in Example 1, except that the cobalt salt used to prepare the catalyst precursor is basic cobalt carbonate, and the obtained precursor is a cobalt-molybdenum bimetallic-oxygen cluster. Present embodiment catalyst preparation method is as follows:

[0053] Dissolve 3.1g of ammonium molybdate in 250ml of water, then add 4.5g of basic cobalt carbonate, heat and stir under reflux to dissolve it; add phosphorous acid to adjust the pH of the system to 4.0, then heat the solution to 60°C and maintain it for 72h to obtain cobalt molybdenum Bimetallic-oxygen cluster powder crystals;

[0054] Mix aluminum hydroxide dry rubber powder and water at a mass ratio of 1:10 to form a slurry at 70°C; then slowly add nitric acid at an acid-to-gel ratio of 1:10 and stir for 30 minutes. Aluminum stone is mixed in a certain proportion and extruded into strips. After forming, it is first dried under infrared lamps, then transferred to an oven a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com