Prepackaged food preservative and preparation method thereof

A technology for pre-packaged food and preservatives, which is applied in food preservation, food extraction, food ultrasonic treatment, etc., can solve problems such as pollution safety and hidden dangers, and achieve the effects of simple ingredients, low production equipment requirements, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

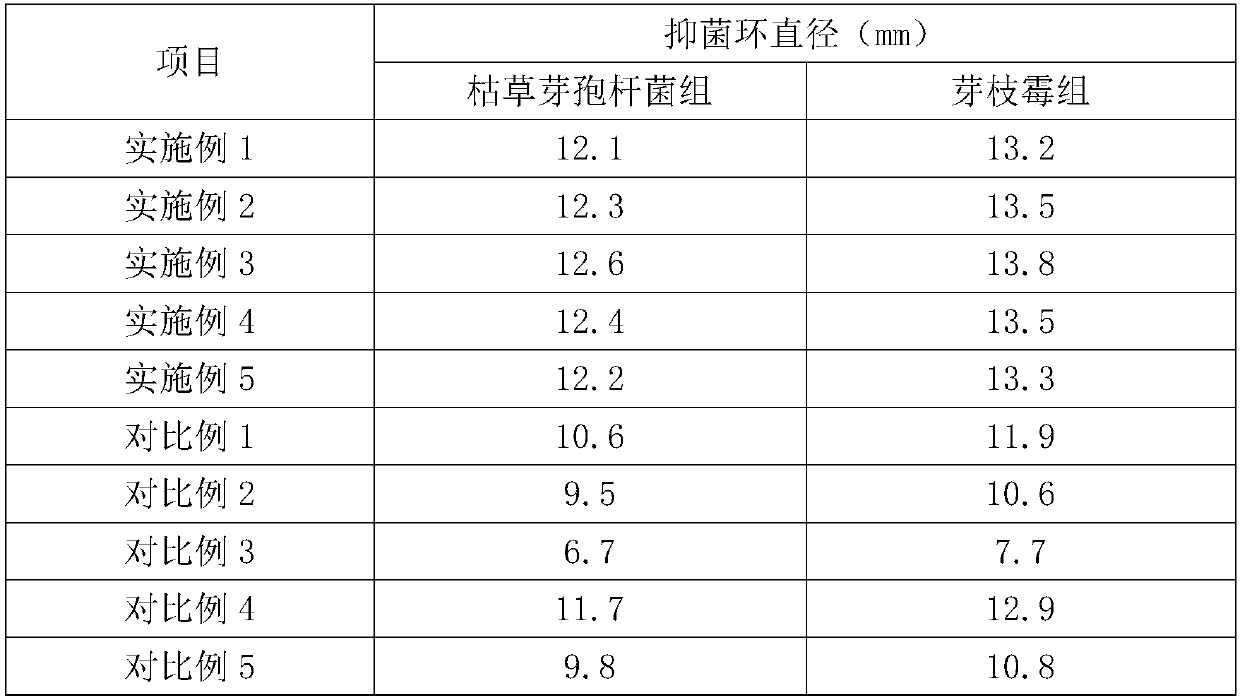

Examples

Embodiment 1

[0020] A prepackaged food preservative, comprising the following raw materials in parts by weight: 10 parts of bitter cabbage, 12 parts of Zhulin Xiao, 9 parts of mountain lettuce, 7 parts of flame grass, 5 parts of licorice, 4 parts of sea powder, and 2 parts of red vine share.

[0021] A preparation method of a prepackaged food preservative, comprising the following steps:

[0022] (1) Weigh the raw materials bitter bitter vegetable, Zhulin Xiao, mountain lettuce, flame grass and licorice by weight, clean and dry, and then crush them into a crushed mixture with a particle size of 0.1 mm, and then add a mass fraction of 4 times the total weight of the crushed mixture Ultrasonic extraction is carried out for 50% ethanol solution, the extraction power is 400W, the extraction time is 20min, and the extraction temperature is 80°C;

[0023] (2) washing and drying sea powder and red flat rattan and grinding them into powders with a particle size of 10 μm;

[0024] (3) Pass the ex...

Embodiment 2

[0026] A prepackaged food preservative, comprising the following raw materials in parts by weight: 13 parts of bitter cabbage, 13 parts of bamboo groves, 10 parts of mountain lettuce, 8 parts of flame grass, 5.5 parts of licorice, 5 parts of sea powder, and 3 parts of red vine share.

[0027] A preparation method of a prepackaged food preservative, comprising the following steps:

[0028] (1) Weigh the raw materials bitter bitter vegetable, bamboo grove, mountain lettuce, flame grass and licorice in parts by weight, clean and dry, and then pulverize into a pulverized mixture with a particle size of 0.2mm, and then add a mass fraction of 4.5 times the total weight of the pulverized mixture Ultrasonic extraction is carried out for 55% ethanol solution, the extraction power is 450W, the extraction time is 25min, and the extraction temperature is 75°C;

[0029] (2) washing and drying the sea powder and red flat rattan and grinding them into powders with a particle size of 13 μm; ...

Embodiment 3

[0032] A prepackaged food preservative, comprising the following raw materials in parts by weight: 15 parts of bitter cabbage, 14 parts of Zhulin Xiao, 11 parts of mountain lettuce, 9 parts of flame grass, 6 parts of licorice, 6 parts of sea powder, and 4 parts of red vine share.

[0033] A preparation method of a prepackaged food preservative, comprising the following steps:

[0034] (1) Weigh the raw materials bitter bitter vegetable, bamboo grove, mountain lettuce, flame grass and licorice in parts by weight, clean and dry, and then pulverize into a pulverized mixture with a particle size of 0.13mm, and then add a mass fraction of 5 times the total weight of the pulverized mixture Ultrasonic extraction is carried out for 60% ethanol solution, the extraction power is 500W, the extraction time is 30min, and the extraction temperature is 70°C;

[0035] (2) washing and drying the sea powder and red flat rattan and grinding them into powders with a particle size of 18 μm;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com