Continuous pressure spray boiling granulation drying system

A technology of boiling granulation and drying system, which is applied in the direction of drying of granular materials, drying of solid materials, and arrangement of drying gas, etc., to achieve the effect of improving the efficiency of granulation and heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

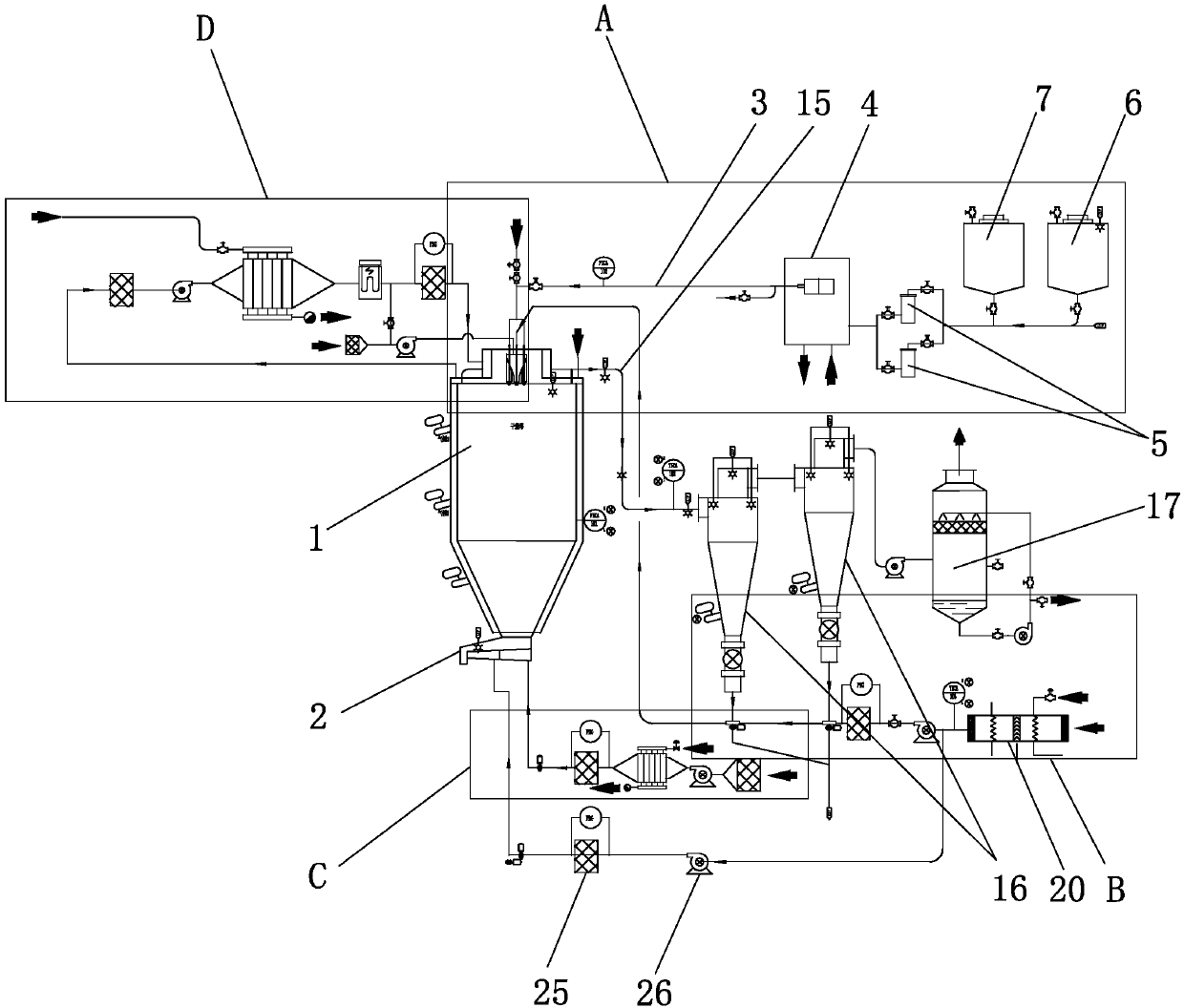

[0034] Embodiment: a kind of continuous pressure spray boiling granulation drying system, such as figure 1 As shown, it includes a vertical drying tower 1, the bottom of the drying tower 1 is provided with a fixed fluidized bed 2, the top of the drying tower 1 is connected with a feed pipe 3, and the feed pipe 3 is connected to the drying tower 1 from near to far. There are high-pressure homogeneous pump 4, feed liquid filter 5, raw material tank 6 and clear water tank 7. The material is mixed with clean water to form a slurry, which is pumped into the feed pipe 3 by the high-pressure homogeneous pump 4 after passing through the feed liquid filter 5 to filter impurities, and the end of the feed pipe 3 is connected to the atomizing nozzle, which is located in the drying tower 1, the slurry is sprayed into the drying tower 1 after being atomized by the atomizing nozzle.

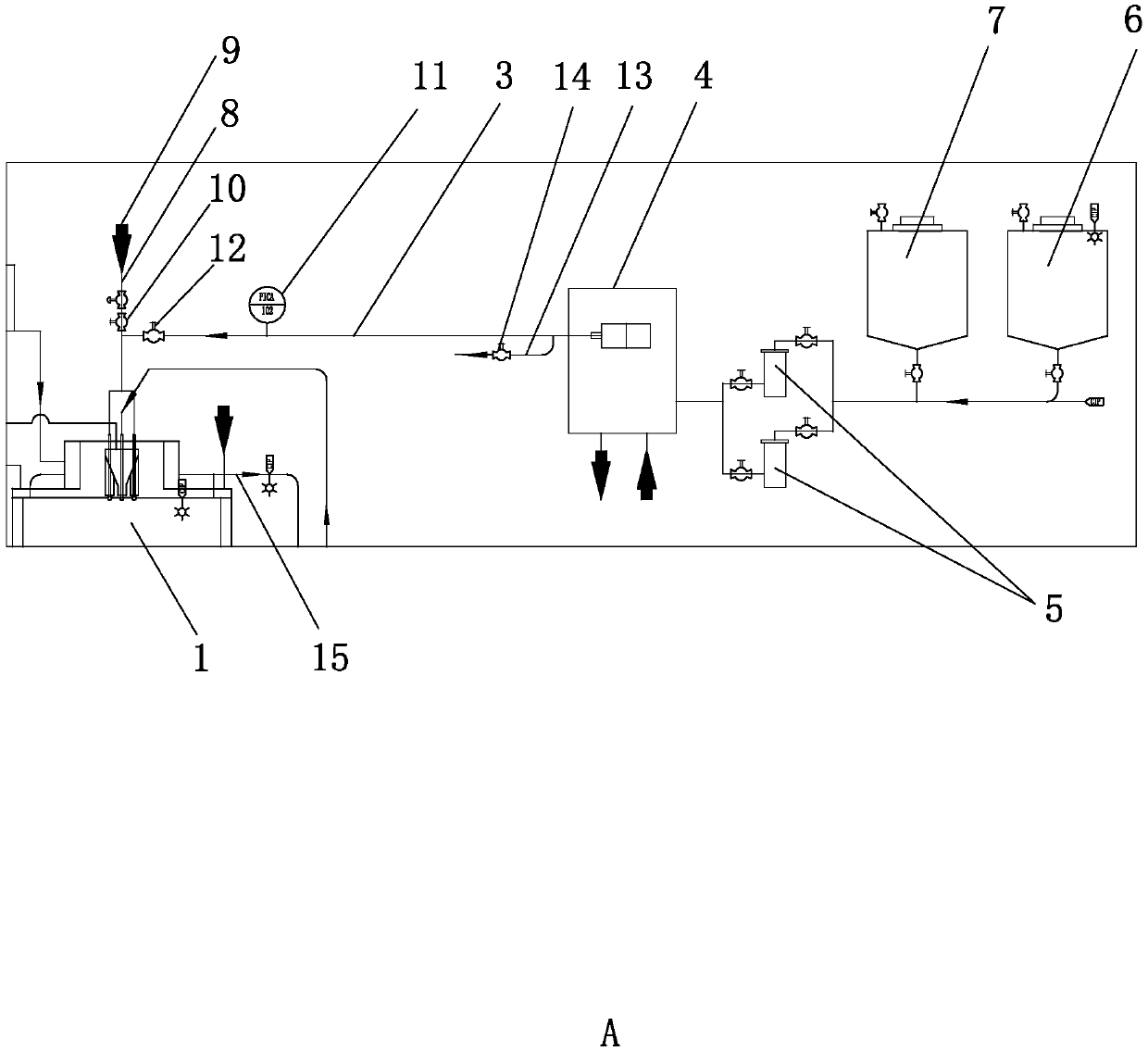

[0035] Such as figure 2 As shown, the feed pipe 3 between the high-pressure homogeneous pump 4 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com