Preparation method of modified lithium ion battery positive electrode material

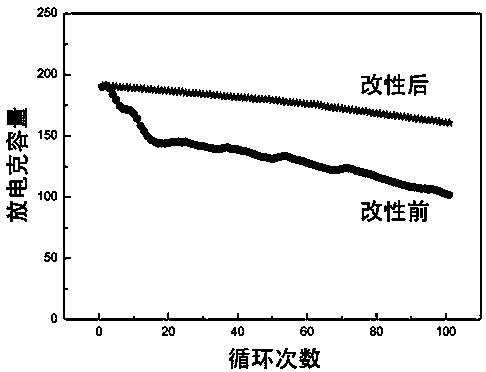

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of not improving Li+ efficiency, rate performance and long cycle performance, etc., and achieve good market promotion value, The effect of reducing the production of inactive substances and the process is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 841.09g of nickel sulfate, 89.22g of manganese sulfate, and 112.46g of cobalt sulfate in 2L of deionized water, and dissolve 320g of sodium hydroxide in 2L of deionized water; add 2L of deionized water to a 10L reactor , add ammonia water dropwise, control the pH value of the reactor to 11.5, control the temperature of the reactor at 50° C., and pass nitrogen protection throughout. Add the above-mentioned dissolved metal salt solution, sodium hydroxide solution and 168.22 g of ammonia water dropwise into the reaction kettle at the same time, and keep the reaction temperature and pH value constant. The filter cake was dried under vacuum at 120°C to obtain a hydroxide precursor; the obtained precursor was mixed with lithium hydroxide at a Li / M molar ratio of 1.05, and the temperature was raised to 750°C at 2°C / min under an oxygen atmosphere 15h obtains lithium-ion battery cathode material. Disperse the above 10g of positive electrode material in 20mL aqueous sol...

Embodiment 2

[0023] Dissolve 946.22g of nickel sulfate, 44.61g of manganese sulfate, and 56.23g of cobalt sulfate in 2L of deionized water, and dissolve 320g of sodium hydroxide in 2L of deionized water; add 2L of deionized water to a 10L reactor , add ammonia water dropwise, control the pH value of the reactor to 11.5, control the temperature of the reactor at 50° C., and pass nitrogen protection throughout. Add the above-mentioned dissolved metal salt solution, sodium hydroxide solution and 168.22 g of ammonia water dropwise into the reaction kettle at the same time, and keep the reaction temperature and pH value constant. The filter cake was dried under vacuum at 120°C to obtain a hydroxide precursor; the obtained precursor was mixed with lithium hydroxide at a Li / M molar ratio of 1.05, and the temperature was raised to 750°C at 2°C / min under an oxygen atmosphere 15h obtains lithium-ion battery cathode material. Disperse the above 10g of positive electrode material in 20mL aqueous solu...

Embodiment 3

[0025] Dissolve 998.79g of nickel sulfate, 22.31g of manganese sulfate, and 28.12g of cobalt sulfate in 2L of deionized water, and dissolve 320g of sodium hydroxide in 2L of deionized water; add 2L of deionized water to a 10L reactor , add ammonia water dropwise, control the pH value of the reactor to 11.5, control the temperature of the reactor at 50° C., and pass nitrogen protection throughout. Add the above-mentioned dissolved metal salt solution, sodium hydroxide solution and 168.22 g of ammonia water dropwise into the reaction kettle at the same time, and keep the reaction temperature and pH value constant. Dry the filter cake under vacuum at 120°C to obtain a hydroxide precursor; mix the obtained precursor with lithium hydroxide at a Li / M molar ratio of 1.05, and raise the temperature to 750°C at 2°C / min under an oxygen atmosphere Insulated for 15 hours to obtain the positive electrode material of lithium ion battery. Disperse the above 10g of positive electrode materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com