High peeling resistance concrete surface protective coating and construction method thereof

A technology for concrete surface and protective coating, applied in hydraulic engineering, marine engineering, construction, etc., can solve the problems of being easily damaged by ice pulling force, coating bubbling, not resistant to water erosion, etc., and achieve the effect of suitable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

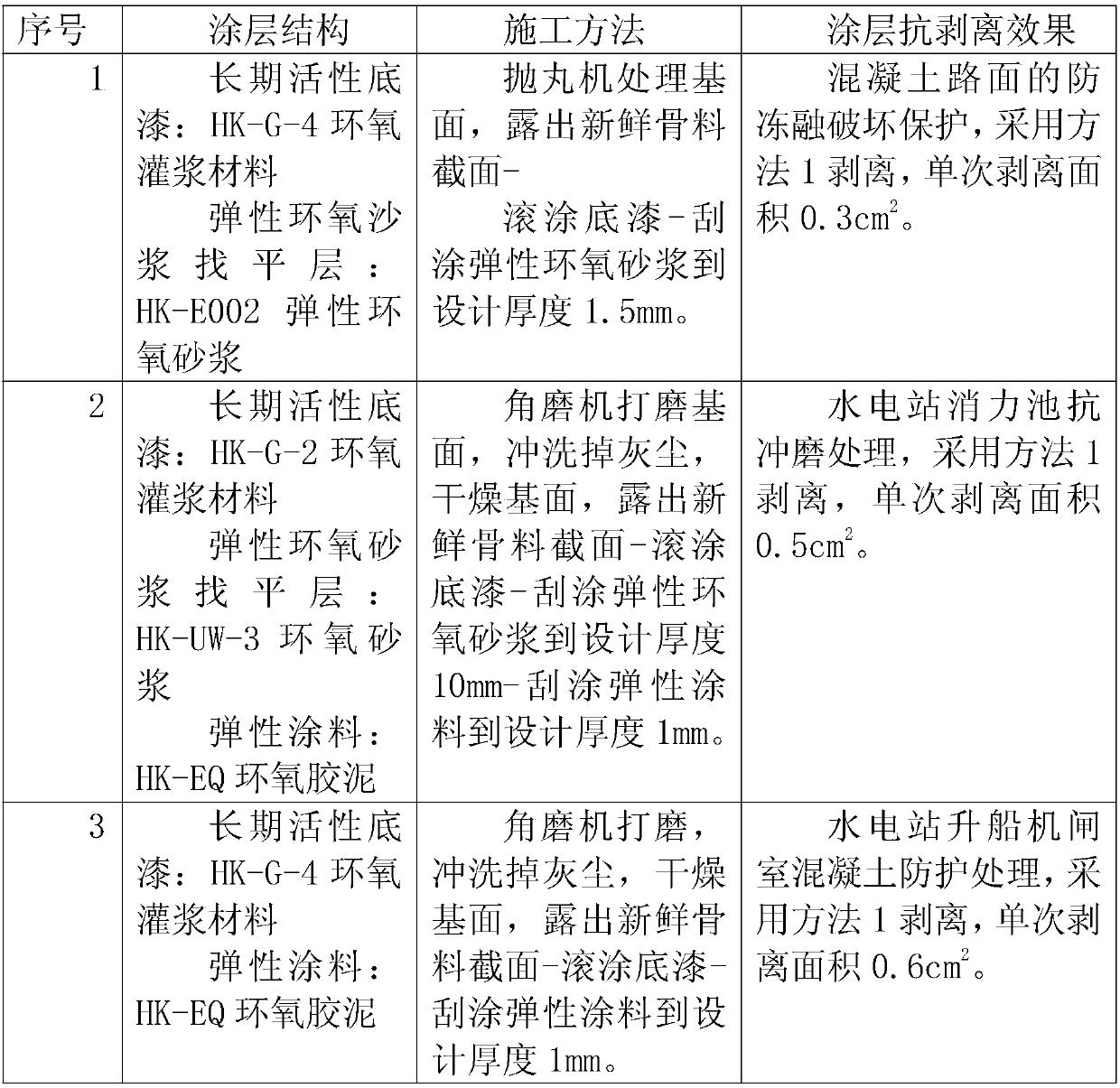

[0039] Example 1: Protection of concrete gravity dam against erosion and freezing and thawing damage.

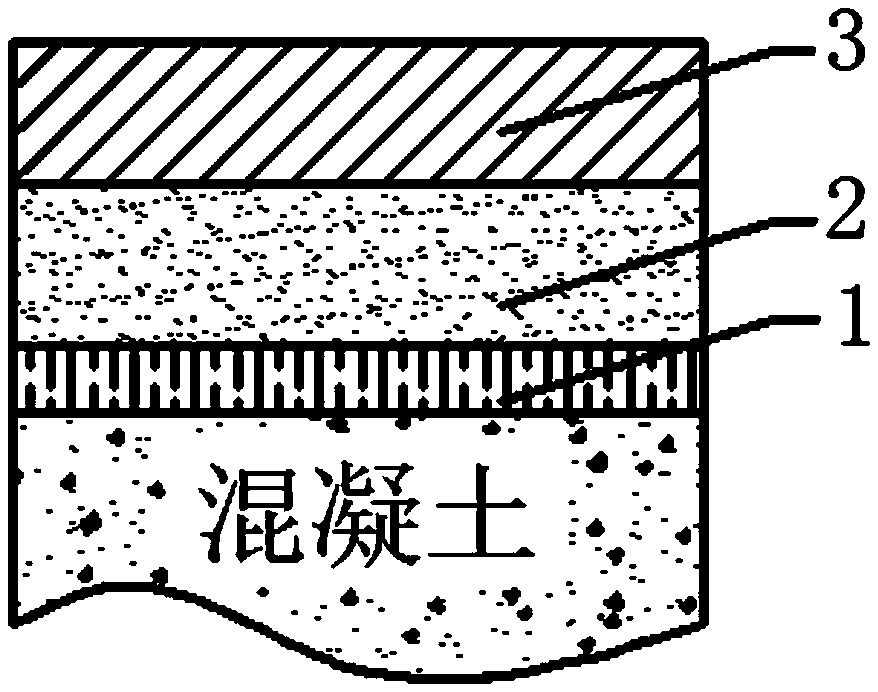

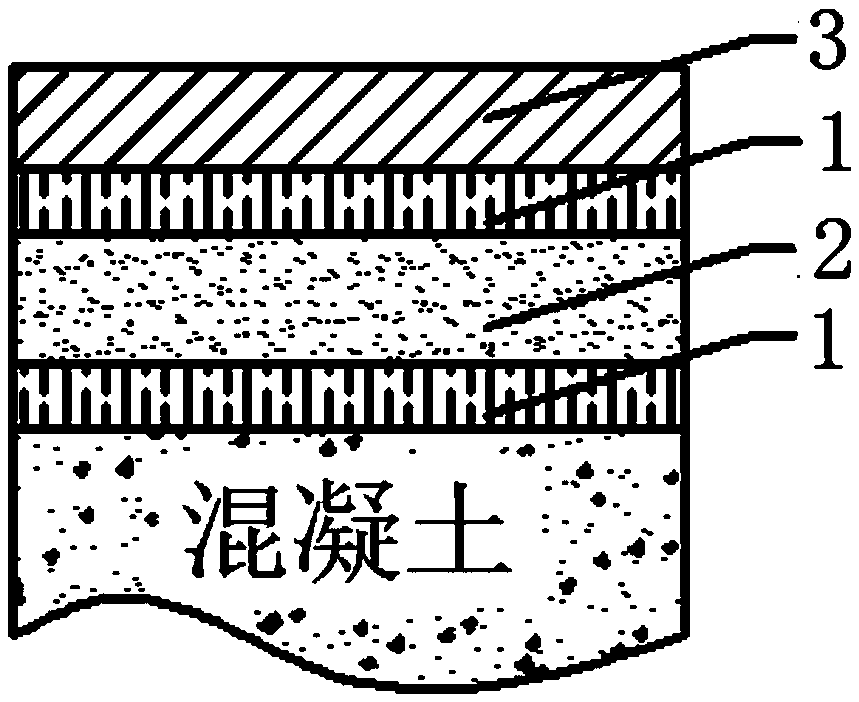

[0040] During the construction period, the temperature is 20°C-27°C, and the relative humidity is 30%-60%. Grind the overflow surface with an angle grinder, wash away the dust with a large amount of water, and expose the aggregate section; roll coat HK-G-4 epoxy grouting material long-term active primer, and the primer will be in the "adhesive force is not low" after 2.5 hours At 0.1MPa, the area of the primer stained during the test does not exceed 10%", this state lasts for 4 hours, during which the first coat of HK-966 elastic paint is scraped, and thereafter HK-966 is scraped once every 24 hours. 966 elastic coating until the design thickness 2mm (see figure 1 ). During roller coating and scraping coating, coat the same part back and forth at least 3 times, and the first coat should be so thin that the substrate of the previous process can be seen (thickness not exce...

example 2

[0041] Example 2: Anti-carbonation protection of concrete gravity dam.

[0042] During the construction period, the temperature is 12°C to 37°C, and the relative humidity is 30% to 92%. Before the protection, the concrete of the dam body was blackened by the adhesion of pollutants, and the concrete on the surface was sandy due to carbonization, and the deepest carbonation depth exceeded 5mm. Use high-pressure water jet cleaning equipment, control the cleaning pressure not to exceed 25MPa, wash away the carbonized layer, and expose the fresh aggregate section. After natural air-drying, roll the HK-G-2 epoxy grouting material long-term active primer. After 2 hours, the primer is in the state of "adhesion is not less than 0.1MPa, and the area of the primer that is stained during the test is not more than 10%". This state lasts for 3 hours. During this period, scrape HK-E003 elastic epoxy mortar. Since the temperature on site exceeds 35°C and the relative humidity exceeds 85%, ...

example 3

[0043] Example 3: Anti-seepage engineering of the upstream dam face of a concrete face rockfill dam.

[0044] During the construction period, the temperature is 5°C to 20°C, and the relative humidity is 60% to 100%. Before the protection, the concrete panel was blackened by the adhesion of pollutants, and the surface was carbonized to form a thin sandy layer. The silt covered the panel. There was a difference in the pouring quality of the panel during construction. The aggregate was exposed in the most serious part, and there were many cracks on the panel. Use high-pressure water jet cleaning equipment, control the cleaning pressure not to exceed 25MPa, wash away pollutants and silt, and expose the fresh aggregate section. After natural air-drying, roll the HK-G-2 epoxy grouting material long-term active primer, and after 4 hours, the primer is in the state of "adhesion is not less than 0.1MPa, and the area of the primer that is stained during the test does not exceed 10%". ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com