Weather-resistant flexible wind power generation cable and production process thereof

A production process and weather resistance technology, which is applied in the direction of insulated cables, flexible cables, cable/conductor manufacturing, etc., to achieve the effects of reducing electrical loss, small conductor gaps, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

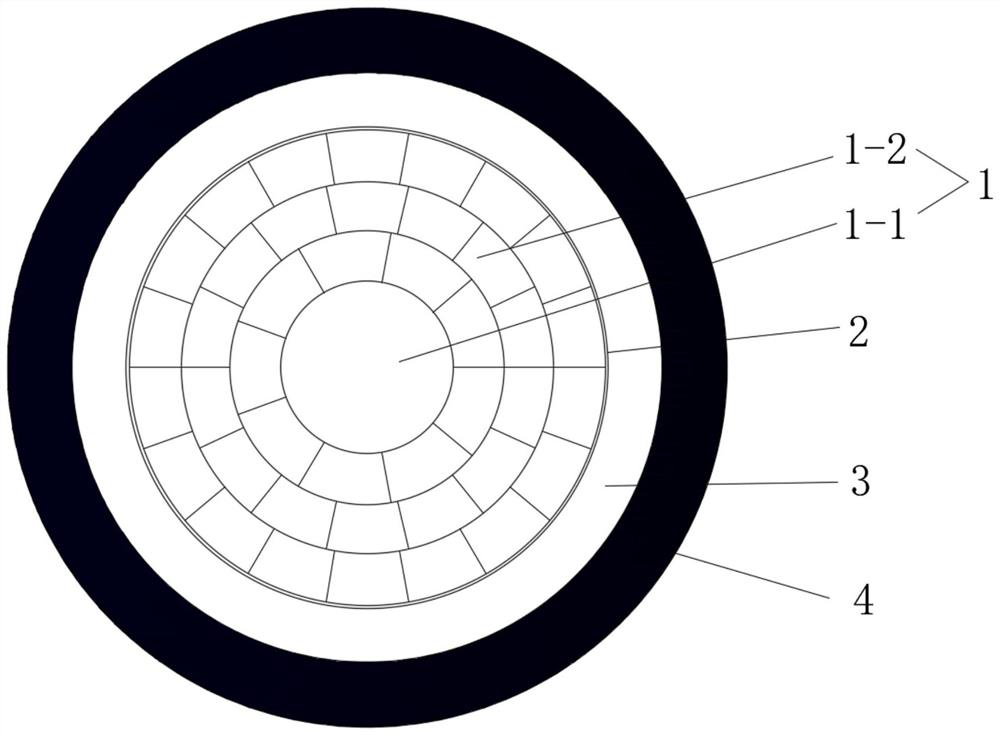

[0035] like figure 1 The weather-resistant flexible wind power generation cable shown includes a conductor 1, an isolation layer 2, an insulating layer 3 and a sheath layer 4 sequentially arranged from the inside to the outside; the conductor 1 is a flexible aluminum alloy profile conductor, which greatly improves the cable's durability. Flexible; the sheath layer is a weather-resistant JC284FR type sheath, which has excellent weather resistance, and an isolation layer 2 is set between the conductor 1 and the insulating layer 3 to homogenize the electric field, prevent the conductor from oxidizing, and reduce the electrical loss. The laying requirements of the fixed section of the open-air steel frame tower for its special use environment.

[0036] The conductor 1 includes a circular guide core 1-1 set in the center and a plurality of profile layers 1-2 closely surrounding the circular core 1-1 in sequence, and each profile layer 1-2 is composed of a plurality of trapezoidal s...

Embodiment 2

[0047] The structure and composition formula of this embodiment are the same as those of embodiment 1, the difference is that the annealing process is different, the annealing temperature of conductor 1 is 400°C, and the annealing time is 3h.

Embodiment 3

[0049] The structure of this embodiment is similar to that of Embodiment 1, the difference is that the formula ratio of the conductor 1 and the sheath layer 4 is different. The composition and proportion of the conductor 1 are calculated by mass percentage as follows: aluminum content 99%, silicon content 0.05%, iron content 0.55%, copper content 0.20%, magnesium content 0.03%, zinc content 0.01%, boron content 0.02%, rare earth content The content is 0.04%, and the rest are impurities.

[0050] The sheath layer 4 adopts JC284FR type sheath, and its composition and proportion are calculated in parts by mass: 45 parts of chlorinated polyethylene, 55 parts of chlorosulfonated polyethylene, 2 parts of ethylene-vinyl acetate copolymer, and 60 parts of talcum powder. 35 parts of calcium carbonate, 55 parts of magnesium hydroxide, 10 parts of carbon black, 70 parts of magnesium oxide, 4 parts of Hongdan, 20 parts of plasticizer DOS, 5 parts of paraffin oil, 2 parts of UV-resistant a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com