Method for dyeing cotton fabric by adopting reactive dyes through foam wet steaming

A technology of reactive dyes and dyeing methods, which is applied in dyeing methods, textiles and papermaking, etc., can solve the problems of reducing the liquid-carrying rate of fabrics, high cost of imported equipment, and difficult process control, so as to shorten the time of wet steam fixation and reduce The effect of increasing the amount of steam and improving the color fixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

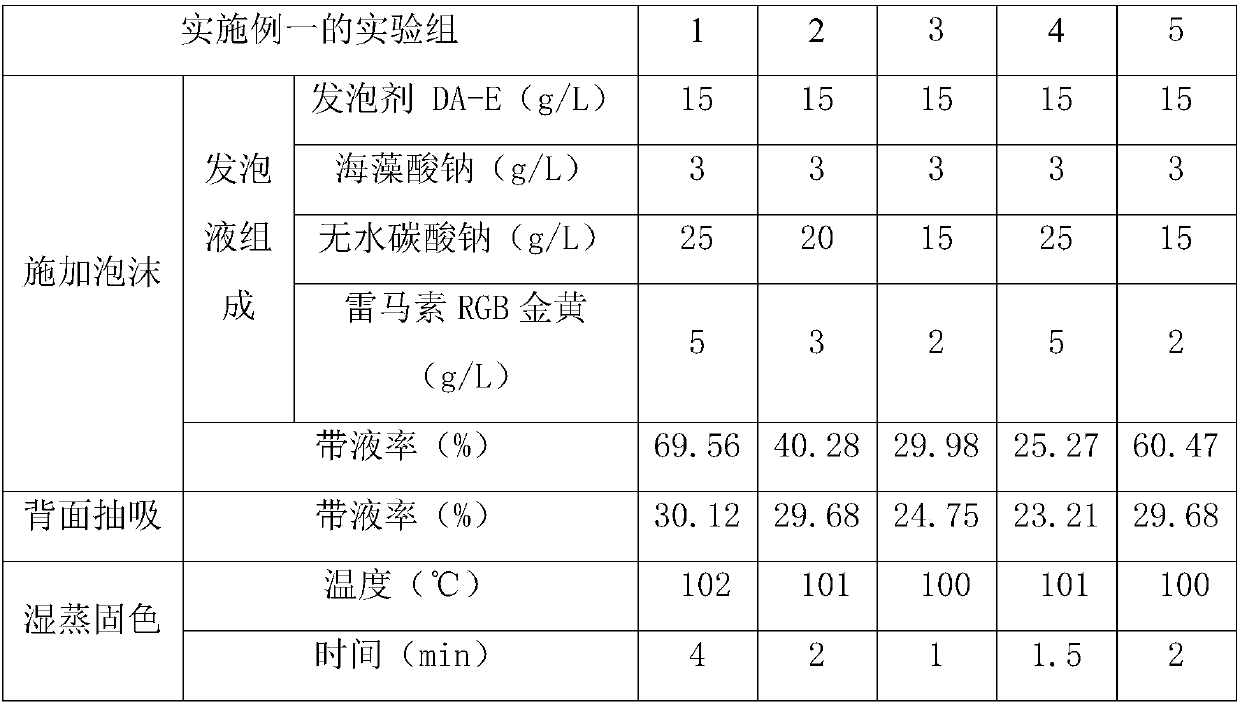

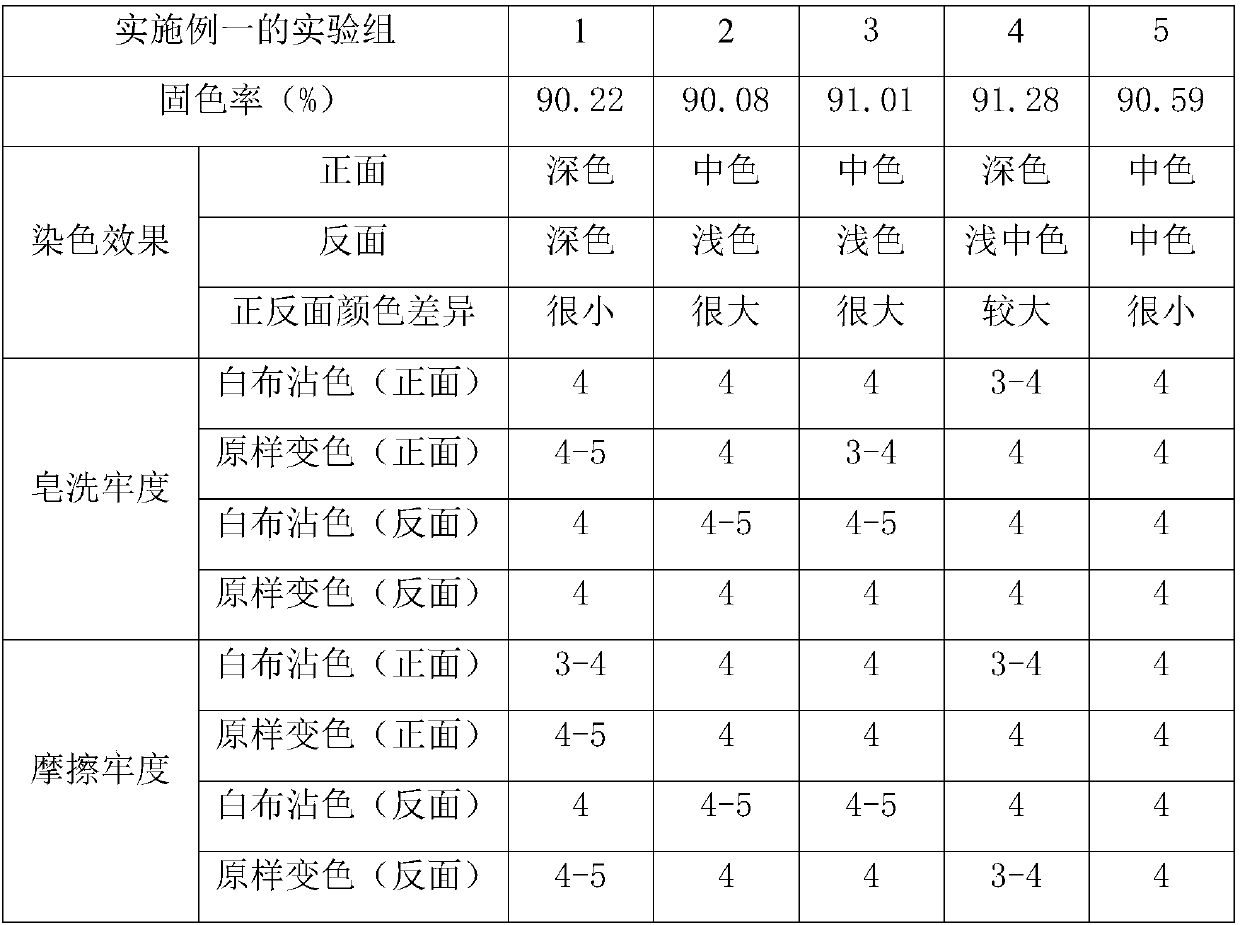

Embodiment 1

[0023] In the present embodiment, the raw materials used in each experimental group, the blowing agent is the commercially available product of Auto Foam Systems Co.Ltd., the reactive dye is the commercially available product of DyStar (Shanghai) Trading Co., Ltd., and other raw materials used are all for commercially available products. The preparation of the foaming liquid refers to the existing method, according to Zhang Xinqing, Meng Qingtao, Zhang Jianfei, etc. Discussion on the foam dyeing process of cotton knitted fabric with reactive dyes. Agent DA-E, foam stabilizer sodium alginate is mainly prepared into foaming liquid, and it is prepared by adding alkali agent and reactive dye solution according to the required color.

[0024] A kind of reactive dye adopts the dyeing method of foam wet steaming to cotton fabric, and its step is as follows:

[0025] (1) Foam application: prepare a foaming solution containing color fixing agent and dye, generate foam through a foamin...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, especially in that:

[0046] In this embodiment, by adjusting the formulation of the foaming solution containing color fixing agent and dye, the amount of foam applied, the position of the foam height limiter, the strength of the suction wind, any one of the process conditions or any combination of several process conditions , can carry out any one of three different dyeing processes in one-side dyeing of fabrics, front and back yin-yang dyeing and front and back same-color dyeing. By adopting the dyeing method of this embodiment, cotton fabrics with different coloring effects can be dyed, and have high soaping fastness and rubbing fastness at the same time, meeting the needs of wearing performance. Dyeing is carried out by adopting the wet steaming dyeing process of reactive dyes in this embodiment. The liquid-carrying rate of the fabric before steaming is as low as 15-35%, which is suitable for dyeing cotton fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com