Composite cloth of superfine denier viscose fiber and elastic mesh cloth and preparation process thereof

A viscose fiber and preparation technology, which is applied in fiber treatment, plant fiber, non-woven fabrics, etc., can solve the problems of weak fiber and base fabric composite, the overall surface style is not dense, composite fabric products are rough, etc., to achieve anti- Good anti-mold and moth effect, excellent air permeability and moisture absorption, and fine surface style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

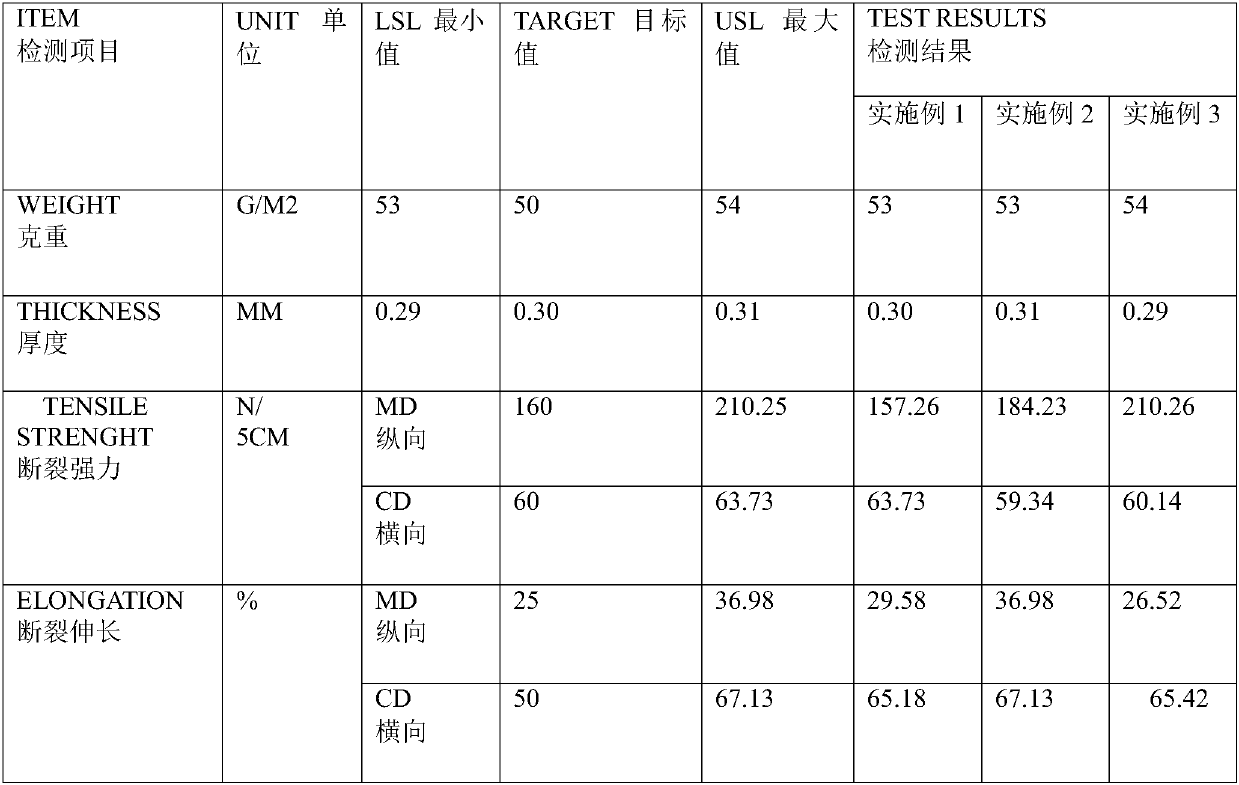

Embodiment 1

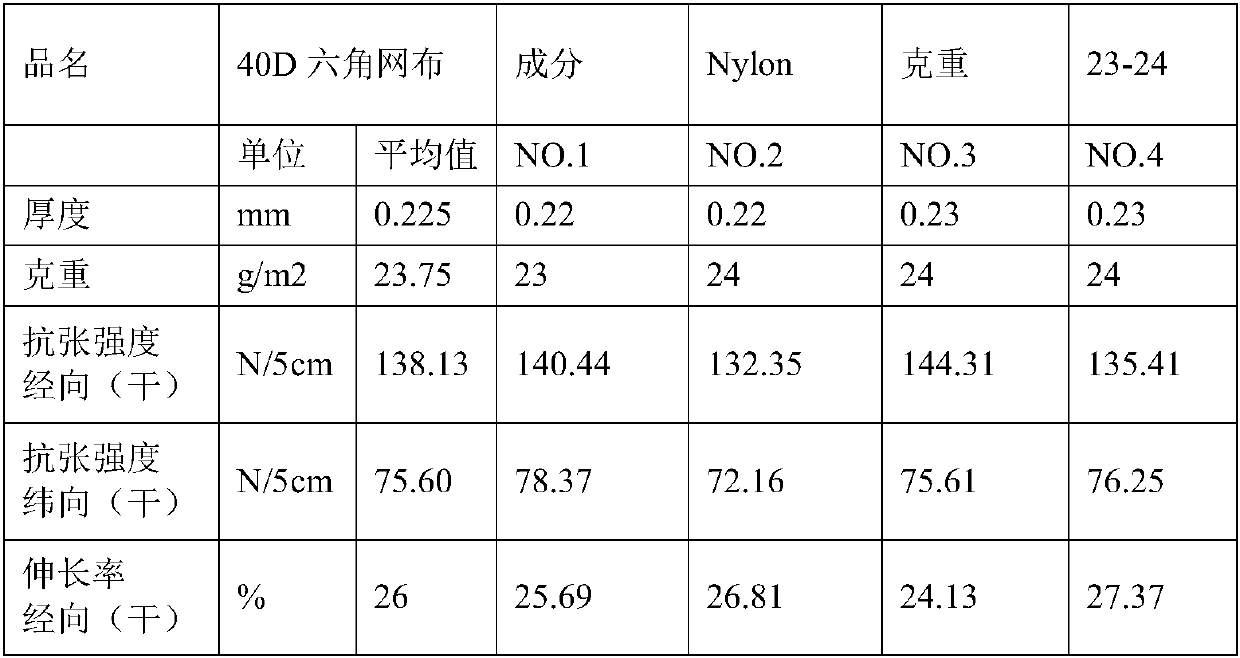

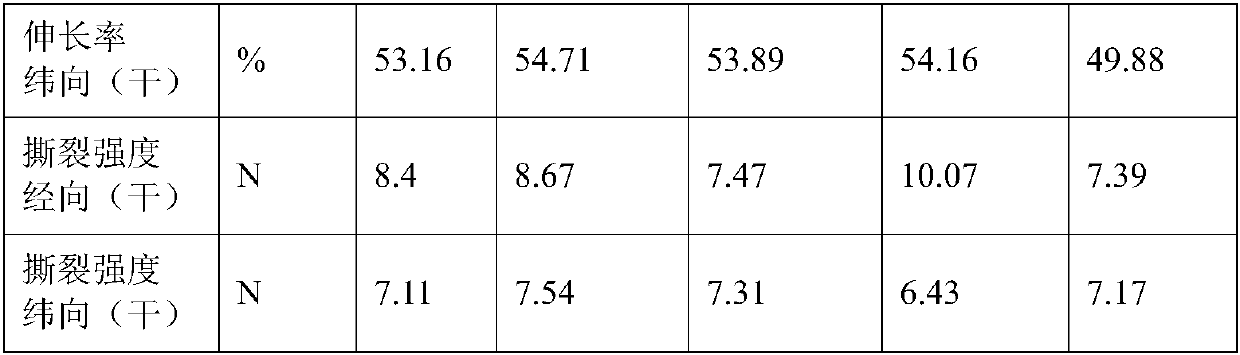

[0037] A composite cloth of ultra-fine viscose fiber and elastic mesh cloth, the composite cloth is made of a mesh fiber layer and a base cloth, the mass ratio of the mesh fiber layer to the base cloth is 52:48, and the mesh The fiber layer is formed by wet method of superfine denier viscose fiber slurry; the base cloth is elastic mesh cloth. Ultrafine denier viscose fibers are modified.

[0038] A preparation process of a composite cloth of ultrafine denier viscose fiber and elastic mesh cloth, the preparation method comprises the following steps:

[0039] (1) Mixing of raw materials: mix clean water and superfine viscose fiber evenly to obtain a slurry, the mass percentage concentration of the superfine viscose fiber in the slurry is 0.65%; superfine viscose fiber amount modification method For: the modification treatment is to put the superfine viscose fiber into the container, then add ethanol to the container, and soak for 5 hours; 4-hydroxybutyric acid copolyester, hea...

Embodiment 2

[0046] A composite cloth of ultra-fine viscose fiber and elastic mesh cloth, the composite cloth is made of a mesh fiber layer and a base cloth, the mass ratio of the mesh fiber layer to the base cloth is 52:48, and the mesh The fiber layer is formed by wet method of superfine denier viscose fiber slurry; the base cloth is elastic mesh cloth. Ultrafine denier viscose fibers are modified.

[0047] A preparation process of a composite cloth of ultrafine denier viscose fiber and elastic mesh cloth, the preparation method comprises the following steps:

[0048] (1) Mixing of raw materials: mix clean water and superfine viscose fiber uniformly to obtain a slurry, the mass percentage concentration of the superfine viscose fiber in the slurry is 1.2%; superfine viscose fiber amount modification method It is: the modification treatment is to put the ultrafine denier viscose fiber into the container, then add ethanol to the container, soak for 3 hours; then add 0.5% 3-hydroxybutyric a...

Embodiment 3

[0055] A composite cloth of ultra-fine viscose fiber and elastic mesh cloth, the composite cloth is made of a mesh fiber layer and a base cloth, the mass ratio of the mesh fiber layer to the base cloth is 52:48, and the mesh The fiber layer is formed by wet method of superfine denier viscose fiber slurry; the base cloth is elastic mesh cloth. Ultrafine denier viscose fibers are not modified.

[0056] A preparation process of a composite cloth of ultrafine denier viscose fiber and elastic mesh cloth, the preparation method comprises the following steps:

[0057] (1) raw material mixing: clear water and superfine denier viscose fiber are evenly mixed to obtain a slurry, and the mass percentage concentration of the superfine denier viscose fiber in the slurry is 1.65%;

[0058] (2) Fiber forming: the slurry is input into the inclined wire former, and the mesh fiber layer is obtained after the inclined wire is formed;

[0059] (3) Bonding: the mesh fiber layer is conveyed downwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com