A kind of composite cloth of direct-spun superfine fiber and elastic mesh cloth and preparation process thereof

A technology of ultra-fine fiber and composite cloth, which is applied in fiber processing, non-woven fabrics, textiles and papermaking, etc. It can solve the problems of weak combination of fiber and base cloth, undense overall surface style, rough composite cloth products, etc., to achieve Good anti-mildew and anti-moth effects, excellent air permeability and moisture absorption, and delicate surface style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

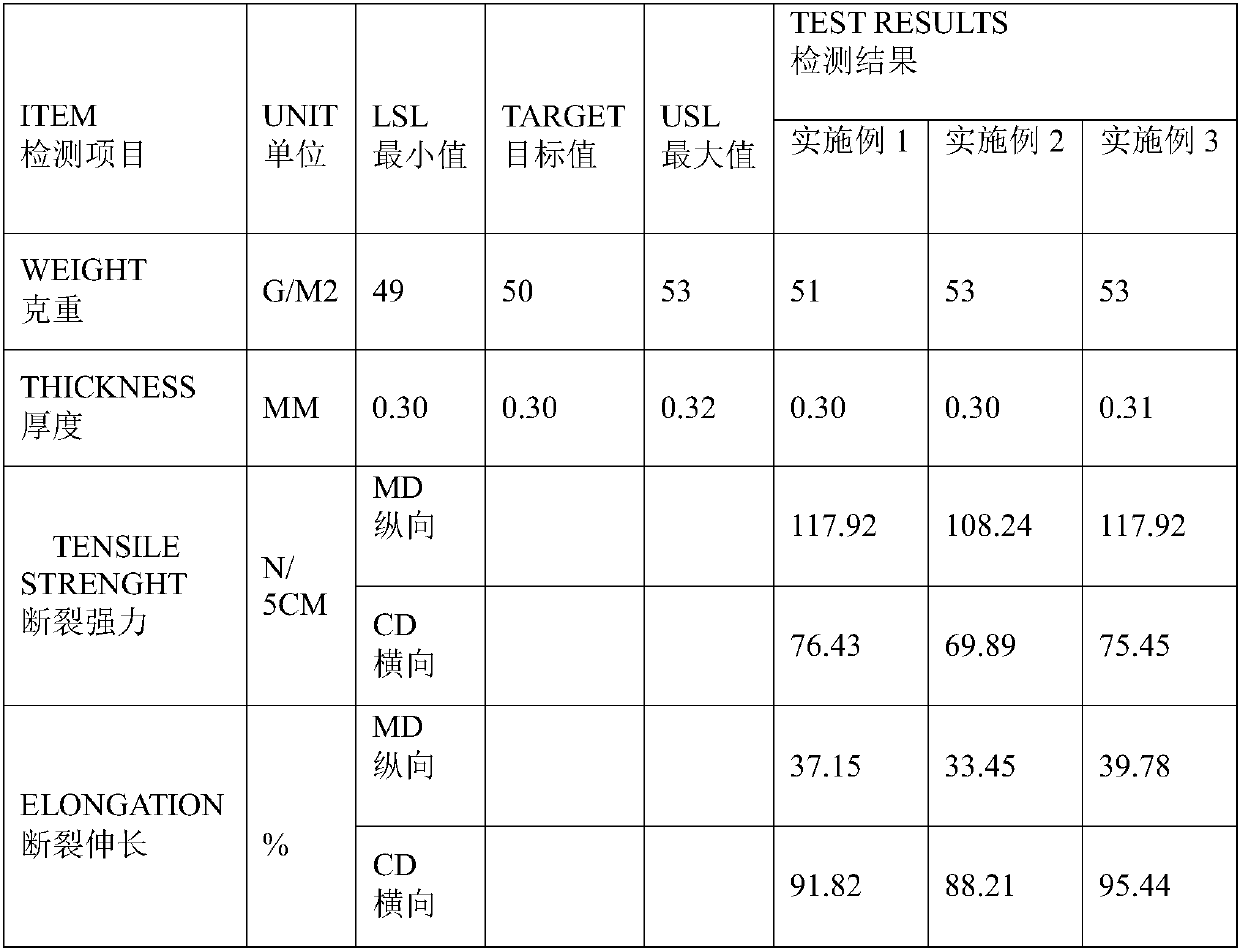

Embodiment 1

[0031] A composite cloth of direct-spun superfine fiber and elastic mesh cloth, the composite cloth is made of a mesh fiber layer and a base cloth, the mass ratio of the mesh fiber layer to the base cloth is 70:30, and the mesh The fiber layer is made of direct-spun superfine fibers; the base cloth is an elastic mesh cloth. Direct spun microfibers are modified.

[0032] A kind of preparation technology of the composite cloth of direct-spun superfine fiber and elastic net cloth, described preparation technology comprises the following steps:

[0033] (1) Mixing of raw materials: mix demineralized water and direct-spinning superfine fibers uniformly to obtain slurry, and the mass percentage concentration of direct-spinning superfine fibers in the slurry is 8%; modification of direct-spinning superfine fibers The method is as follows: the modification treatment is to put the direct-spun superfine fiber into a container, then add ethanol to the container, and soak for 3 hours; th...

Embodiment 2

[0040] A composite cloth of direct-spun superfine fiber and elastic mesh cloth, the composite cloth is made of a mesh fiber layer and a base cloth, the mass ratio of the mesh fiber layer to the base cloth is 55:45, and the mesh The fiber layer is wet-formed by direct-spun superfine fiber slurry; the base cloth is cotton gauze. Direct spun microfibers are modified.

[0041] A kind of preparation technology of the composite cloth of direct-spun superfine fiber and elastic net cloth, described preparation technology comprises the following steps:

[0042] (1) Mixing of raw materials: mix demineralized water and direct-spun superfine fibers uniformly to obtain slurry, and the mass percentage concentration of direct-spun superfine fibers in the slurry is 7.2%; modification of direct-spun superfine fibers The method is as follows: the modification treatment is to put the direct-spun superfine fiber into a container, then add ethanol to the container, and soak for 5 hours; -4-hydro...

Embodiment 3

[0049] A composite cloth of direct-spun superfine fiber and elastic mesh cloth, the composite cloth is made of a mesh fiber layer and a base cloth, the mass ratio of the mesh fiber layer to the base cloth is 55:45, and the mesh The fiber layer is wet-formed by direct-spun superfine fiber slurry; the base cloth is cotton gauze. Direct spun microfibers are not modified.

[0050] A kind of preparation technology of the composite cloth of direct-spun superfine fiber and elastic net cloth, described preparation technology comprises the following steps:

[0051] (1) raw material mixing: demineralized water and direct-spun superfine fibers are mixed evenly to obtain a slurry, and the mass percentage concentration of direct-spun superfine fibers in the slurry is 6.5%;

[0052] (2) Fiber forming: the slurry is input into the inclined wire former, and the mesh fiber layer is obtained after the inclined wire is formed;

[0053] (3) Bonding: the mesh fiber layer is conveyed downward fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com