Preparation method of crosslinked polymer electrolyte, semisolid polymer battery and preparation method thereof

A polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc., can solve the problem of low room temperature conductivity and achieve high dissociation rate, good compatibility, good stability and rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

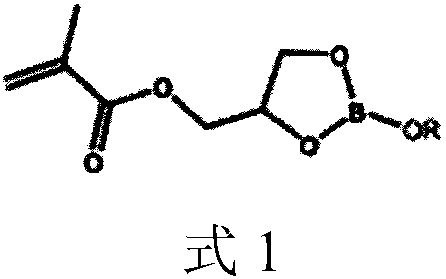

[0024] It is prepared by reacting monoglycerol methacrylate and trimethyl borate according to the stoichiometric ratio of 1:1, then adding polyoxyethylene alcohol with hydroxyl groups at both ends for bridging, stirring and reacting for 18 hours; drying to remove solvent, after Column chromatography, obtains borate cross-linking agent structural formula as

[0025]

[0026] Under the protective atmosphere of argon with the content of water and oxygen less than 1ppm, the borate crosslinking agent of the above structure, the polymer monomer of polyethylene glycol diacrylate, lithium hexafluorophosphate, ethylene carbonate modifier and azo Diisobutyronitrile initiators are mixed to obtain a pre-polymerization solution, in which the mass ratio of the above substances is 20:10:10:59:1, and polymer electrolyte membrane can be obtained by in-situ polymerization on polypropylene diaphragm material at 70°C for 1 hour . After testing, the conductivity of the electrolyte membrane at ...

Embodiment 2

[0029] It is prepared by reacting monoglyceride methacrylate and trimethyl borate according to the stoichiometric ratio of 1:1, then adding polyvinyl alcohol acrylate for reaction, stirring for 18 hours; drying to remove solvent, and column chromatography to obtain The structural formula of borate ester crosslinking agent is

[0030]

[0031] Under the protective atmosphere of argon with water and oxygen content less than 1ppm, the borate crosslinking agent of the above structure, polymer monomer of polyethylene glycol diacrylate, lithium bistrifluoromethanesulfonimide, Propylene carbonate modifier and azobisisoheptanonitrile initiator are mixed to obtain a pre-polymerization solution, wherein the mass ratio of the above-mentioned substances is 20:10:20:49.5:0.5, at 60 ° C, on the cellulose non-woven membrane The polymer electrolyte membrane can be obtained by in-situ polymerization of materials for 10 h. After testing, the conductivity of the electrolyte membrane at room ...

Embodiment 3

[0034] It is prepared by reacting monoglycerol methacrylate and trimethyl borate according to the stoichiometric ratio of 1:1, then adding polyvinyl alcohol acrylate for reaction, stirring for 10 hours; drying to remove acetonitrile, and obtaining boron by column chromatography The structural formula of ester crosslinking agent is

[0035]

[0036]Under the protective atmosphere of argon with water and oxygen content less than 1ppm, the borate crosslinking agent with the above structure, polymer monomer of isooctyl methacrylate, lithium oxalate difluoroborate, tetraethylene glycol dimethyl Ether modifier and cyclohexanone isoperoxide initiator are mixed to obtain a pre-polymerization solution, wherein the mass ratio of the above-mentioned substances is 10:5:5:79.5:0.5, at 50°C, in-situ polymerization on glass fiber for 15h A polymer electrolyte membrane can be obtained. After testing, the conductivity of the electrolyte membrane at room temperature is 2.8×10 -3 S / cm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Electrochemical window | aaaaa | aaaaa |

| Charge and discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com