Preparation of phosphorus-containing bismaleimide and application thereof in flame-retardant epoxy resin

A kind of bismaleimide, maleimide technology, applied in the application of flame retardant epoxy resin, the preparation field of phosphorus-containing bismaleimide, can solve the flame retardant performance of epoxy resin, mechanical It is difficult to balance the performance and heat resistance, so as to achieve the effect of significant flame retardant effect, mild reaction conditions and improved flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

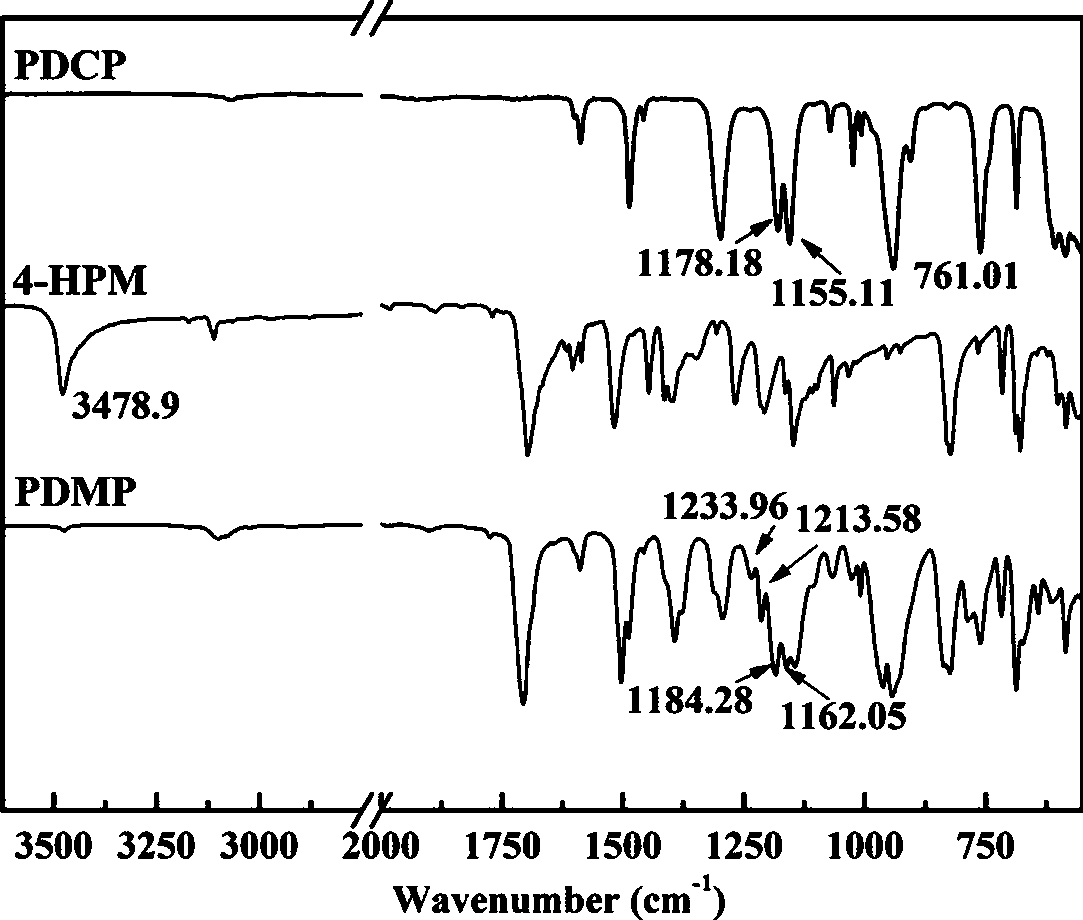

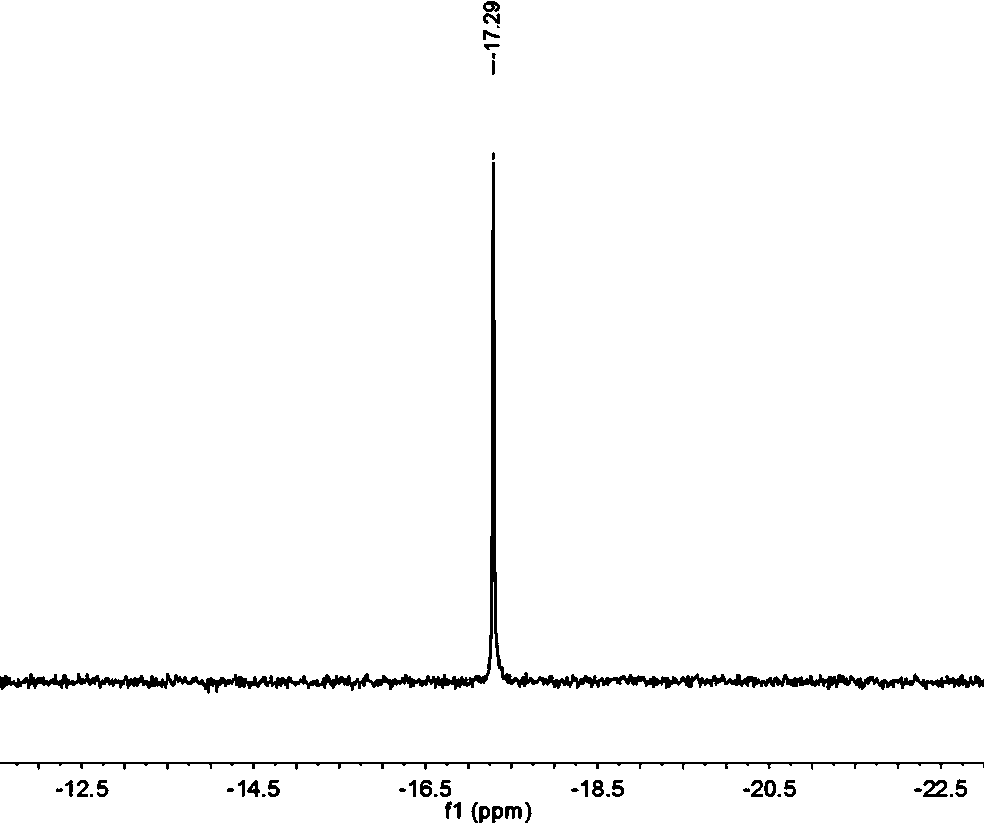

[0028] The preparation method of described phosphorus-containing bismaleimide:

[0029] (1) In a 250mL reaction vessel equipped with stirring, add 7.65g of N-(4-hydroxyphenyl)maleimide and 50mL of tetrahydrofuran under ice-cooling, and dissolve them by magnetic stirring; after completely dissolving, add triethyl Amine 5.3g, continue stirring until uniformly mixed. Then, at 5-7° C., 4.5 g of a mixed solution of phenyl dichlorophosphate and tetrahydrofuran was added dropwise into the above-mentioned reaction vessel, and the system gradually produced white precipitates.

[0030] (2) After the solution was added dropwise, the system was reacted at room temperature for 10 h, the white precipitate triethylamine hydrochloride was filtered and then distilled under reduced pressure, purified and dried with ethyl acetate and petroleum ether to obtain a light yellow solid product, the yield was was 91.7%.

Embodiment 2

[0032] The preparation method of described phosphorus-containing bismaleimide:

[0033] (1) In a 250mL reaction vessel equipped with stirring, add 7.65g of N-(4-hydroxyphenyl)maleimide and 50mL of tetrahydrofuran under ice-cooling, and dissolve them by magnetic stirring; after completely dissolving, add triethyl Amine 4.89g, continue stirring until uniformly mixed. Then, at 5-7° C., 4.5 g of a mixed solution of phenyl dichlorophosphate and tetrahydrofuran was added dropwise into the above-mentioned reaction vessel, and the system gradually produced white precipitates.

[0034] (2) After the solution was added dropwise, the system was reacted at room temperature for 12 hours, the white precipitate triethylamine hydrochloride was filtered and then distilled under reduced pressure, purified and dried with ethyl acetate and petroleum ether to obtain a light yellow solid product, the yield was 92.5%.

Embodiment 3

[0041] The preparation method of described phosphorus-containing bismaleimide:

[0042] (1) In a 250mL reaction vessel equipped with stirring, add 7.65g of N-(4-hydroxyphenyl)maleimide and 50mL of tetrahydrofuran under ice-cooling, and dissolve them by magnetic stirring; after completely dissolving, add triethyl Amine 5.35g, continue to stir until evenly mixed. Then, at 5-7° C., 4.5 g of a mixed solution of phenyl dichlorophosphate and tetrahydrofuran was added dropwise into the above-mentioned reaction vessel, and the system gradually produced white precipitates.

[0043] (2) After the solution was added dropwise, the system was reacted at room temperature for 8 hours, the white precipitate triethylamine hydrochloride was filtered and then distilled under reduced pressure, purified and dried with ethyl acetate and petroleum ether to obtain a light yellow solid product, the yield was 95.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com