Strontium-doped precious metal oxide oxygen evolution electrocatalyst and preparation method thereof

A precious metal oxide, electrocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to improve catalyst performance, reduce precious metal loading, equipment less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of Strontium-doped Iridium Oxide Oxygen Evolution Electrocatalyst

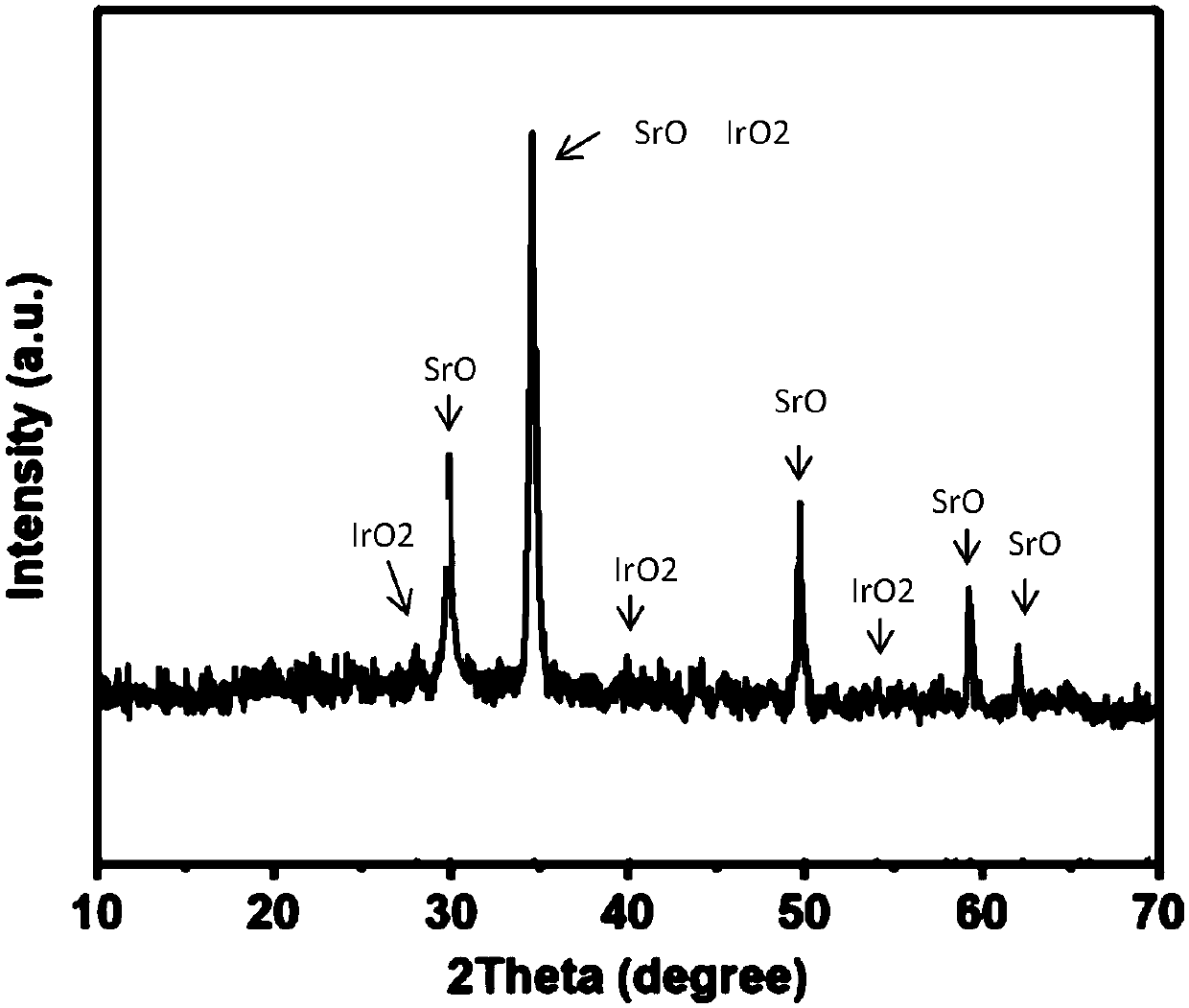

[0037] Prepare 20mL of 0.1mol / L chloroiridic acid; prepare 21.85mL of 0.6mol / L strontium hydroxide solution at 80°C; mix the two, cool down to 20°C, centrifuge at 10000rpm, take the precipitate, and calcinate the precipitate at 550°C for 2h , to get 0.55g, SrO, IrO 2 Strontium-doped iridium oxide oxygen evolution electrocatalyst with a molar ratio of 1:2.

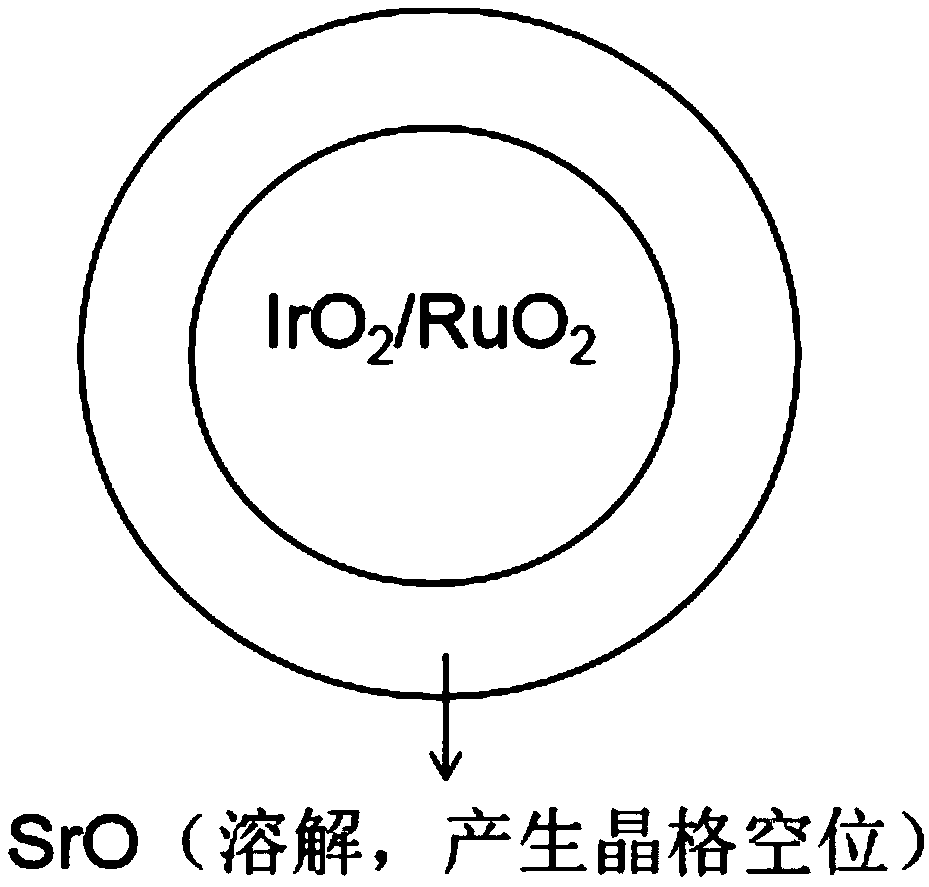

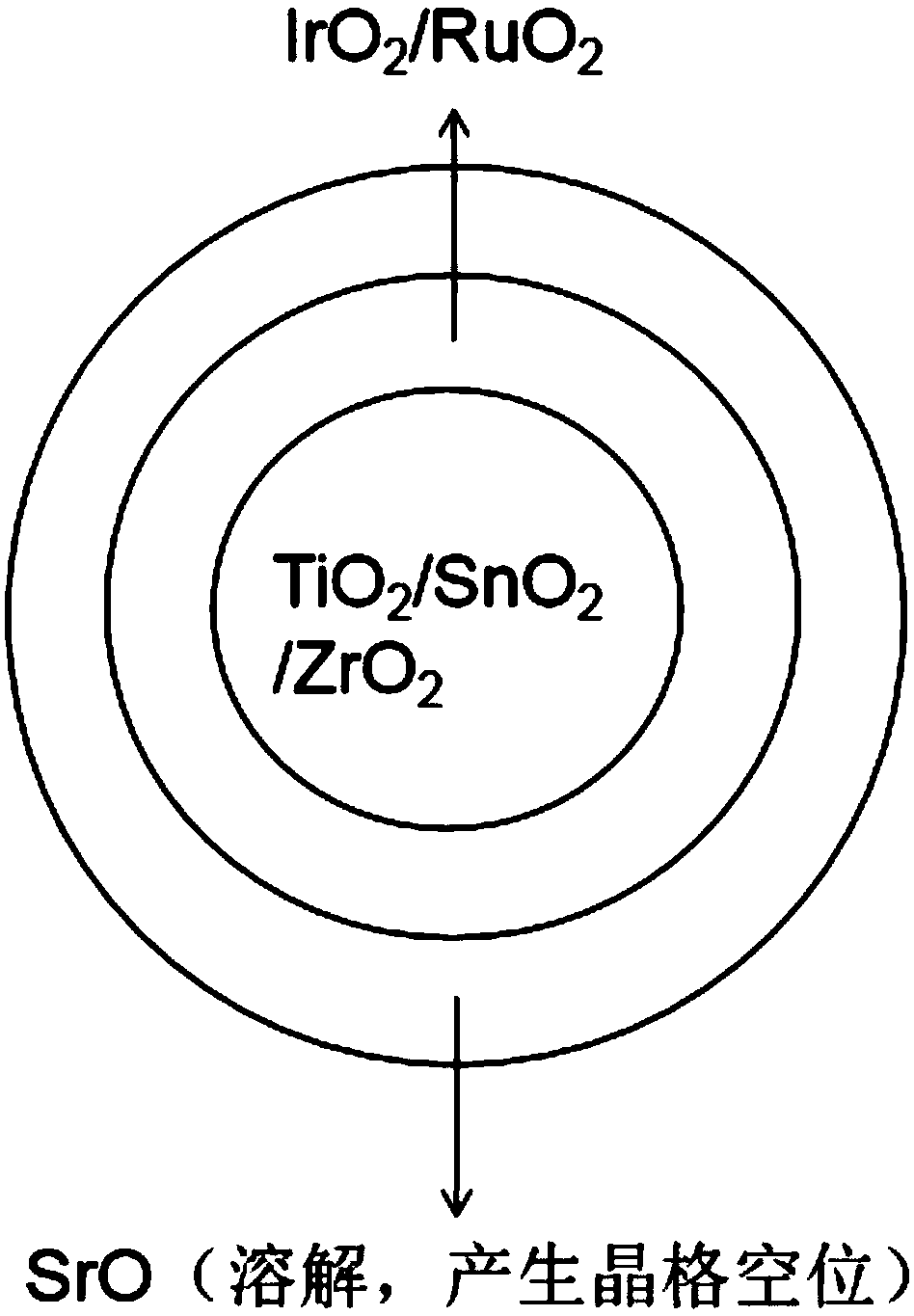

[0038] Prepare a loading capacity of 2.5mg / cm 2 The oxygen evolution electrode has been tested and the current density is 10mA / cm 2 , the overpotential of the catalyst is 0.28V, and at a current density of 100mA / cm 2 , the overpotential of the catalyst is 0.66V; at 100mA / cm 2 Under the test condition of current density, after 2.5 hours of stability test, the current density decays to 5%. figure 1 It is a schematic structural diagram of the oxygen evolution electrocatalyst prepared in Examples 1-8, the core body is a noble metal oxide...

Embodiment 2

[0040] Preparation of Strontium-doped Iridium Oxide Oxygen Evolution Electrocatalyst

[0041]Prepare 20mL of 0.1mol / L chloroiridic acid; prepare 28.45mL of 0.6mol / L strontium hydroxide solution at 80°C; mix the two, cool down to 20°C, centrifuge at 10000rpm, take the precipitate, and calcinate the precipitate at 550°C for 2h , to get 0.86g, SrO, IrO 2 Strontium-doped iridium oxide oxygen evolution electrocatalyst with a molar ratio of 2:1.

[0042] Prepare a loading capacity of 2.5mg / cm 2 The oxygen evolution electrode has been tested and the current density is 10mA / cm 2 , the overpotential of the catalyst is 0.33V, and at a current density of 100mA / cm 2 , the overpotential of the catalyst is 0.74V; at 100mA / cm 2 Under the test condition of current density, after 2.5 hours of stability test, the current density decays to 5.5%.

Embodiment 3

[0044] Preparation of Strontium-doped Iridium Oxide Oxygen Evolution Electrocatalyst

[0045] Prepare 20 mL of 0.02 mol / L chloroiridic acid; prepare 8 mL of 0.15 mol / L strontium hydroxide solution at 90 °C; mix the two, cool down to 30 °C, centrifuge at 10000 rpm, take the precipitate, and calcinate the precipitate at 400 °C for 4 hours. The strontium-doped iridium oxide oxygen evolution electrocatalyst was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com