Method of forming semiconductor device

A semiconductor and device technology, applied in the field of semiconductor devices and their formation, can solve the problems of poor performance of semiconductor devices, affecting the threshold voltage of semiconductor devices, etc., and achieve the effect of improving device performance and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] As mentioned in the background art, with the increase in density and the reduction in size of semiconductor devices, the electrical performance of semiconductor devices still needs to be improved.

[0032] Since the size of the semiconductor device is smaller, the fin size of the device is also smaller, the capacity for doping ions is also smaller, and the state of doping ions after heat treatment is also more unstable, which affects the performance of the fin transistor device. It is also more obvious, and will be described below in conjunction with the accompanying drawings.

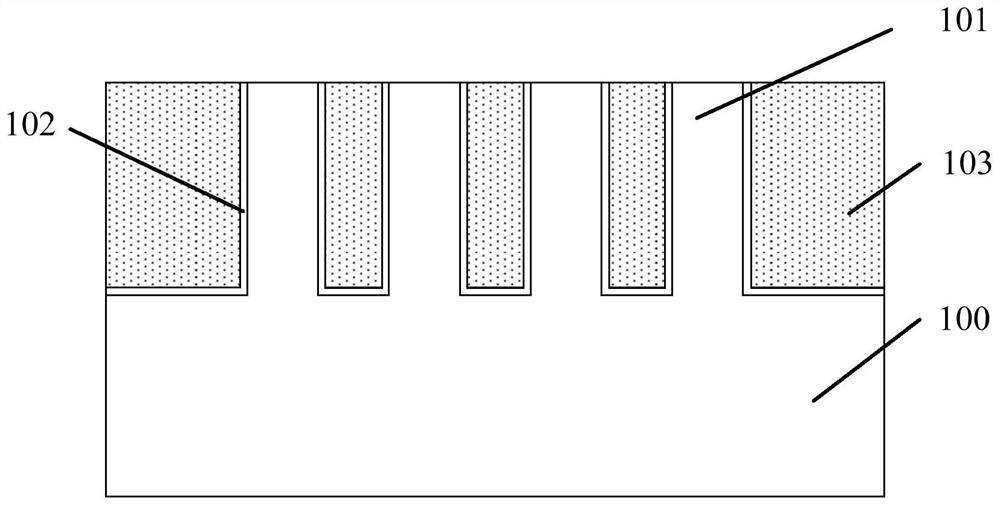

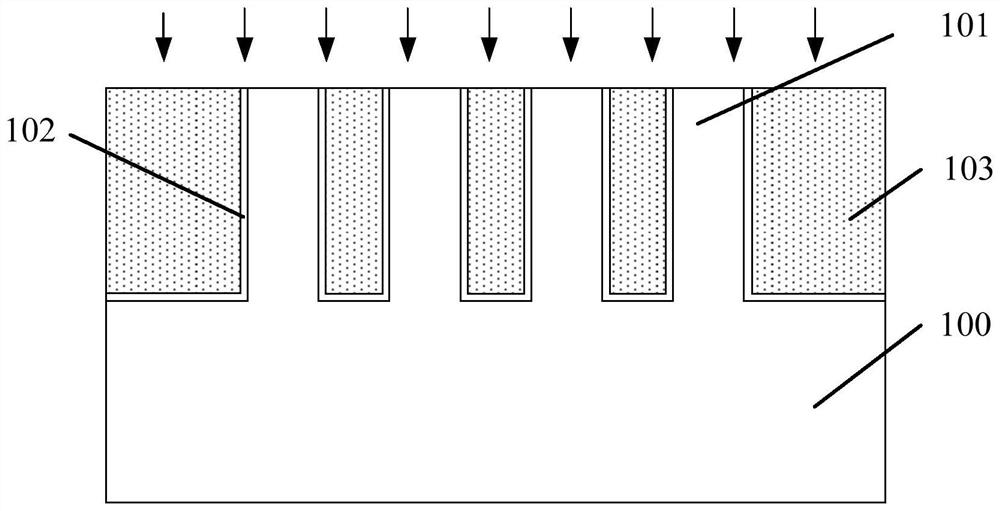

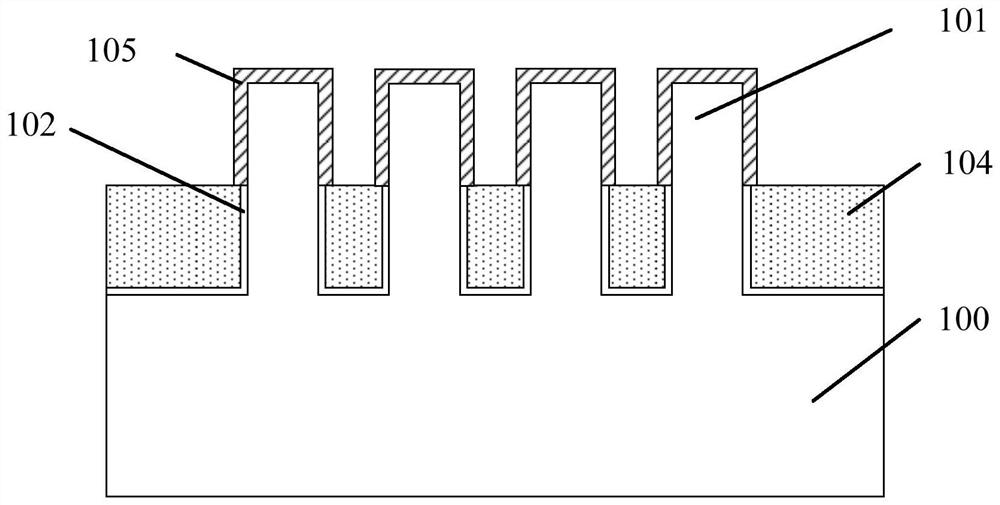

[0033] Figure 1 to Figure 3 It is a schematic cross-sectional structure diagram of the formation process of a semiconductor device.

[0034] Please refer to figure 1 , providing a substrate 100 with a fin 101 on the substrate, forming a protective layer 102 on the fin and the substrate, the protective layer 102 covering the substrate and the sidewall of the fin, exposing the top of the fin, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com