A method for preparing polyselenourea/polyselenoamide by multi-component polymerization of elemental selenium, isonitrile/alkyne and amine

A technology of elemental selenium and selenourea, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of strong tolerance, high atom utilization rate, and low monomer toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

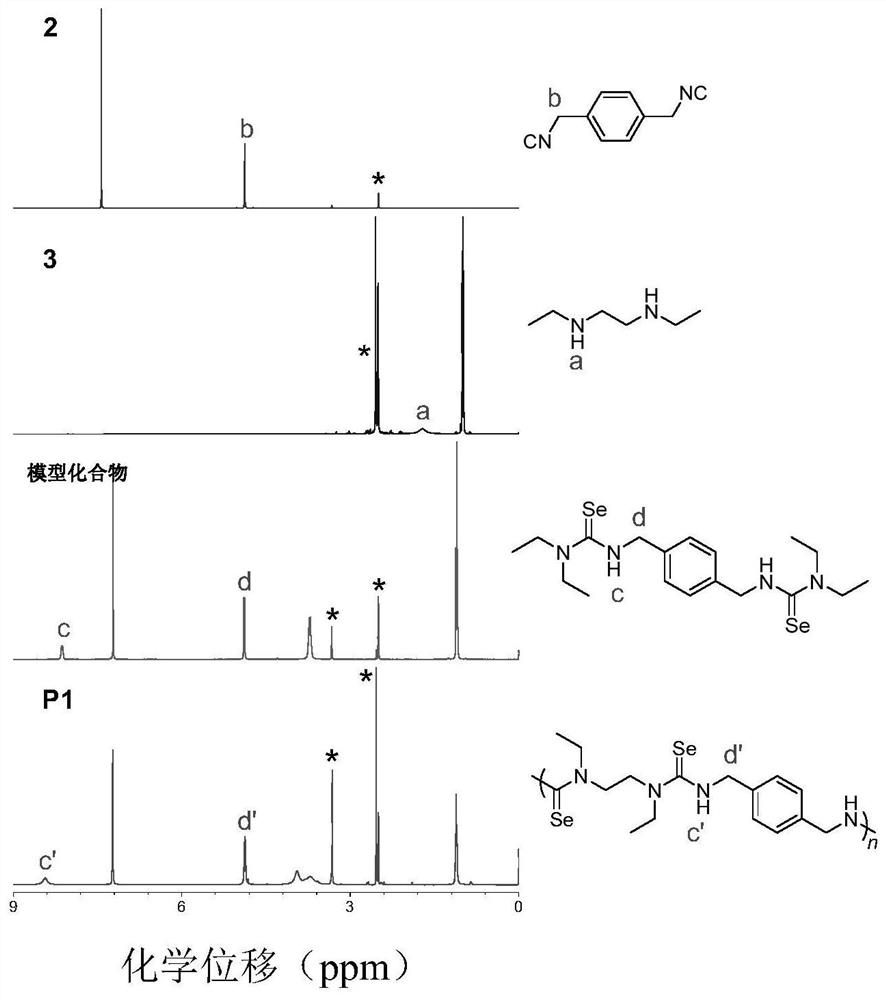

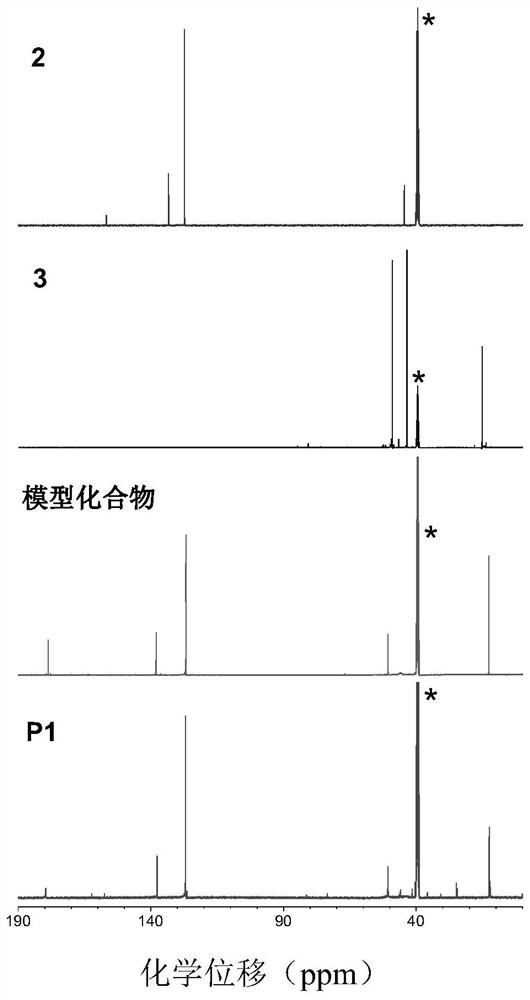

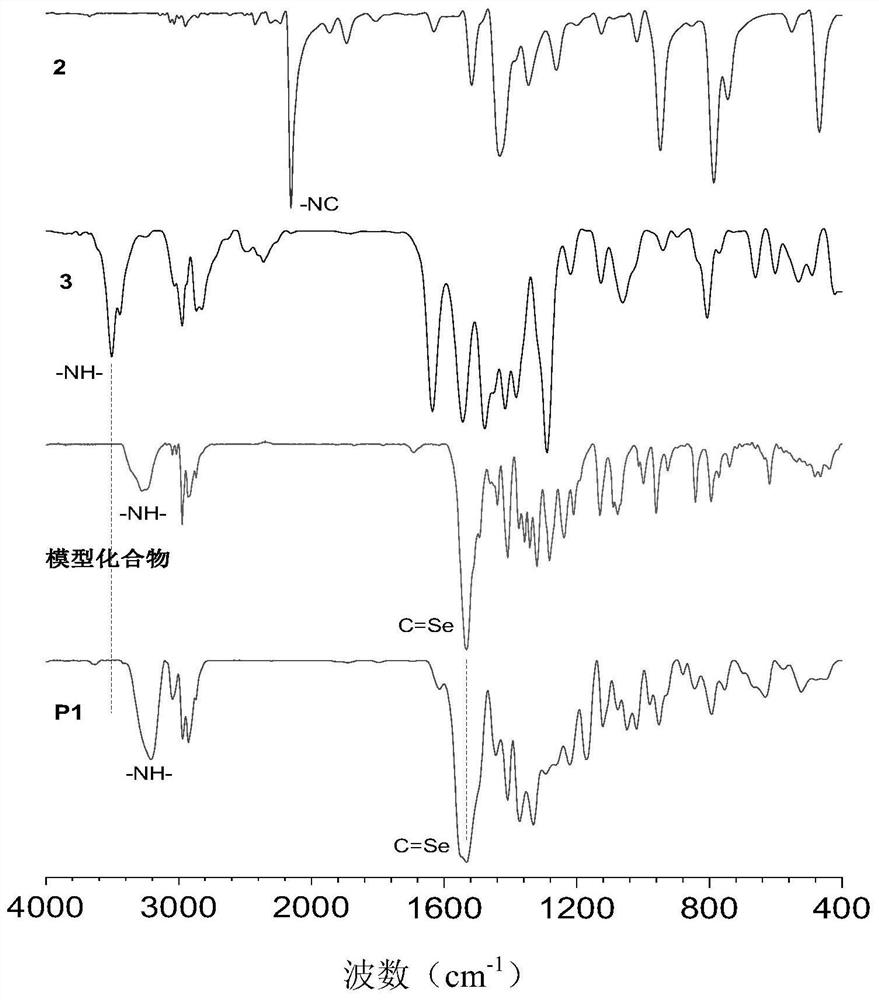

[0036] A polyselenourea, its structural formula P1:

[0037]

[0038] The polyselenourea is prepared by multi-component polymerization reaction of elemental selenium, isonitrile and amine, and its specific reaction equation is as formula (1):

[0039]

[0040] (1) Monomers 1 and 3 can be purchased;

[0041] (2) The synthesis method of monomer 2 is as described in the literature (J.Am.Chem.Soc.2018, 140, 6156–6163);

[0042] (3) The preparation steps of the polyselenourea are as follows: 1.2mmol (0.096g) of monomer 1, 0.3mmol (0.047g) of monomer 2, vacuum exchanged for N 2 Afterwards, 0.3 mL DMSO and 0.3 mmol (44.3 μL) of monomer 3 were injected sequentially, and the system was heated to 100° C. and then stirred at 400 rpm for 1 minute. After the reaction, dilute the reaction system with 2mL DMSO, filter the unreacted monomer 1 from the system, drop it into the precipitant anhydrous methanol for sedimentation, and obtain 0.117g polymer P1 after standing, filtering, and ...

Embodiment 2

[0047] In this example, the reaction time in Example 1 was changed to 40° C. to obtain 0.117 g of a polymer with a yield of 90% and a molecular weight of 43 800 g / mol.

Embodiment 3

[0049] A kind of polyselenourea, shown in its structural formula P2:

[0050]

[0051] The polyselenourea is prepared by multi-component polymerization reaction of elemental selenium, isonitrile and amine, and its specific reaction equation is as formula (2):

[0052]

[0053] (1) The obtaining method of monomer 1 and 2 is described in Example 1;

[0054] (2) The synthesis method of monomer 4 is as described in the literature (J.Am.Chem.Soc.2018, 140, 6156–6163);

[0055] (3) The preparation steps of the polyselenourea are as follows: 1.2mmol (0.096g) monomer 1, 0.3mmol (0.047g) monomer 2, 0.3mmol (0.109G) monomer were sequentially added into a 10mL polymerization tube 4. Vacuum for N 2 Afterwards, 0.3 mL of DMSO was injected, and the system was heated to 100° C. and then stirred at a rate of 400 rpm for 1 minute. After the reaction, dilute the reaction system with 2mL DMSO, filter the unreacted monomer 1 from the system, drop it into the precipitant anhydrous methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com