Method for synthesizing methyl 2-methyl-4-acetyl benzoate

A technology for the synthesis of methyl acetyl benzoate, which is applied to the preparation of carboxylic acid esters, chemical instruments and methods, and condensation to prepare carbonyl compounds, etc., can solve the problems of high price, highly toxic potassium cyanide, and toxic carbon monoxide, etc., and achieve The effect of high reaction yield, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

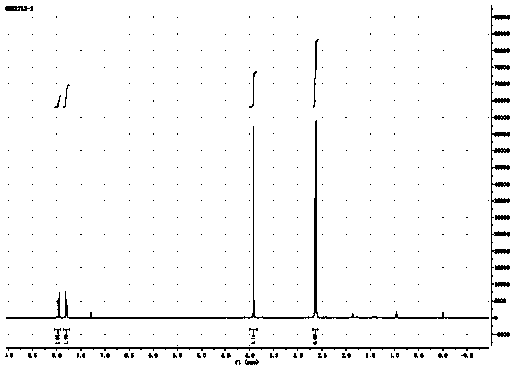

Image

Examples

Embodiment 1

[0017] Preparation of 4-fluoro-3-methylacetophenone

[0018] Add 11 grams (0.1mol) of 2-fluorotoluene, 33.4 grams (0.25mol) of aluminum trichloride, and 100ml of dichloromethane into a 250ml three-necked flask. The temperature is controlled at -5°C, and 8.6 grams (0.11 mol) Acetyl chloride, after the dropwise addition is completed, warm up to normal temperature, react for 2 hours, TLC detection, after the reaction is complete, add 50mL of ice water and 25mL of dilute hydrochloric acid at 0 ℃, separate, wash, dry, and rotary evaporate , to obtain 13.5 grams of colorless liquid, yield 88%.

[0019] Preparation of 3-methyl-4-cyanoacetophenone

[0020] Add 7.6 grams (0.05mol) of 4-fluoro-3-methylacetophenone, 21.2 grams (0.05mol) of potassium ferrocyanide, 10% tetrabutylammonium bromide, 100ml of N,N-Dimethylformamide, heat up to 140°C, react for 16 hours, TLC detection, after the reaction of the raw materials, cool down to 80°C, add 100ml of ethyl acetate, reflux for 1 hour, st...

Embodiment 2

[0026] Preparation of 4-fluoro-3-methylacetophenone:

[0027] Add 11 grams (0.1mol) of 2-fluorotoluene, 33.4 grams (0.25mol) of aluminum trichloride, and 100ml of chloroform into a 250ml three-necked flask. The temperature is controlled at -5°C, and 8.6 grams (0.11 mol) Acetyl chloride, after the dropwise addition is completed, warm up to normal temperature, react for 2 hours, TLC detection, after the reaction is complete, add 50mL of ice water and 25mL of dilute hydrochloric acid at 0 ℃, separate, wash, dry, and rotary evaporate , to obtain 14 grams of colorless liquid, yield 91%.

[0028] Preparation of 3-methyl-4-cyanoacetophenone:

[0029] Add 7.6 grams (0.05mol) of 4-fluoro-3-methylacetophenone, 21.2 grams (0.05mol) of potassium ferrocyanide, 10% tetrabutylammonium bromide, 100ml of N-methylimidazole, heat up to 160°C, react for 14 hours, TLC detection, after the reaction of the raw materials, cool down to 80°C, add 100ml of ethyl acetate, reflux for 1 hour, stop heatin...

Embodiment 3

[0035] Preparation of 4-fluoro-3-methylacetophenone

[0036] Add 11 grams (0.1mol) of 2-fluorotoluene, 16.2 grams (0.1mol) of ferric chloride, and 100ml of carbon tetrachloride into a 250ml three-necked flask. The temperature is controlled at -5°C, and 8.6 grams ( 0.11mol) of acetyl chloride, after the dropwise addition was completed, the temperature was raised to 80°C, reacted for 8 hours, and detected by TLC. After the reaction was completed, 50mL of ice water and 25mL of dilute hydrochloric acid were added at 0°C, separated, washed, and dried. Rotary evaporation gave 7.8 g of a colorless liquid with a yield of 50.7%.

[0037] Preparation of 3-methyl-4-cyanoacetophenone

[0038] Add 7.6 grams (0.05mol) of 4-fluoro-3-methylacetophenone, 21.2 grams (0.05mol) of potassium ferrocyanide, 10% tetrabutylammonium bromide, 100ml of N-butylimidazole, heat up to 140°C, react for 14 hours, TLC detection, after the reaction of the raw materials, cool down to 80°C, add 100ml of ethyl ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com