Preparation method of environment-friendly stain-resistant sponge brick

A stain-resistant, sponge brick technology, used in biocide-containing paints, antifouling/underwater coatings, coatings, etc., to achieve the effects of high splitting tensile strength, simplified production steps, and strong filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the described environment-friendly stain-resistant sponge brick comprises the following steps:

[0023] S1: Mix cement, aggregate, and medium sand with water (water-material ratio 0.6) to obtain the base material;

[0024] S2: Add Additive A and Additive B to the base material prepared in step S1 for mixing. After mixing and stirring evenly, the material is vibrated and pressurized at 20MP to form, demolded, painted with paint, and naturally cured for 27 days to obtain a brick body ;

[0025] S3: The brick body prepared in step S2 is coated with a stain-resistant paint, and left to stand at room temperature for 24 hours to obtain an environmentally friendly stain-resistant sponge brick.

[0026] The additive A includes the following raw materials in parts by weight: 5-8 parts of ferrous sulfate, 4-5 parts of magnesium fluorosilicate, 8-12 parts of sodium silicate, and 8-15 parts of porous calcium phosphate.

[0027] The additive B is in parts...

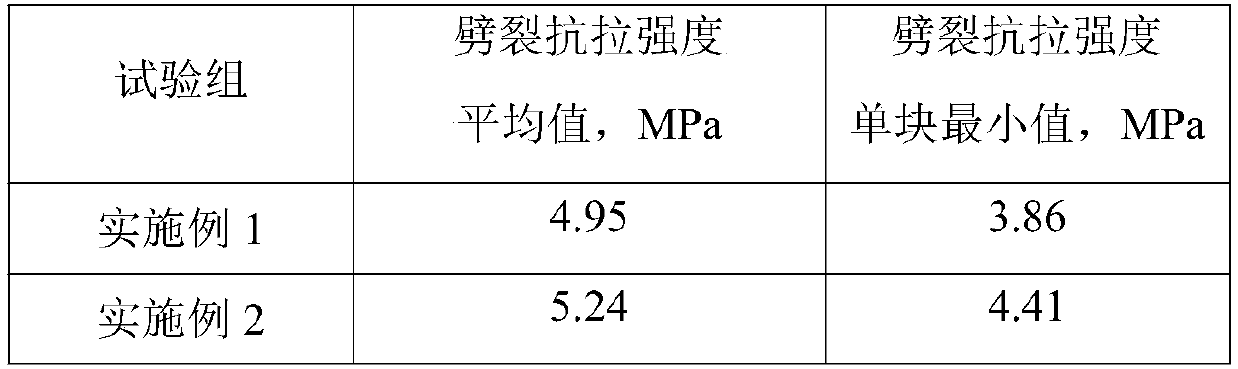

Embodiment 1

[0036] An environment-friendly and stain-resistant sponge brick, the components of which are in parts by weight, including the following raw materials: 15 parts of cement, 16 parts of aggregate with a particle diameter of 0.2-0.35mm, and 5 parts of medium sand with a particle diameter of 0.35-0.5mm 1.5 parts of additive A, 3.2 parts of additive B, 1 part of pigment, 1 part of stain-resistant paint;

[0037] The preparation method of the described environment-friendly stain-resistant sponge brick comprises the following steps:

[0038] S1: Mix cement, aggregate, and medium sand with water (water-material ratio 0.6) to obtain the base material;

[0039] S2: Add Additive A and Additive B to the base material prepared in step S1 for mixing. After mixing and stirring evenly, the material is vibrated and pressurized at 20MP to form, demolded, painted with paint, and naturally cured for 27 days to obtain a brick body ;

[0040] S3: The brick body prepared in step S2 is coated with ...

Embodiment 2

[0050] An environment-friendly and stain-resistant sponge brick, the components of which are in parts by weight, including the following raw materials: 20 parts of cement, 28 parts of aggregate with a particle diameter of 0.2-0.35mm, and 8 parts of medium sand with a particle diameter of 0.35-0.5mm 1 part, 4 parts of additive A, 7.8 parts of additive B, 3 parts of pigment, 1 part of stain-resistant paint;

[0051] The preparation method of the described environment-friendly stain-resistant sponge brick comprises the following steps:

[0052] S1: Mix cement, aggregate, and medium sand with water (water-material ratio 0.6) to obtain the base material;

[0053] S2: Add Additive A and Additive B to the base material prepared in step S1 for mixing. After mixing and stirring evenly, the material is vibrated and pressurized at 20MP to form, demolded, painted with paint, and naturally cured for 27 days to obtain a brick body ;

[0054] S3: The brick body prepared in step S2 is coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com