A kind of natural polysaccharide-based medical antibacterial hydrocolloid dressing and preparation method thereof

A natural polysaccharide and antibacterial water technology, applied in the field of medical supplies, can solve problems such as unsatisfactory effects, achieve good skin adhesion strength, high liquid absorption rate, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

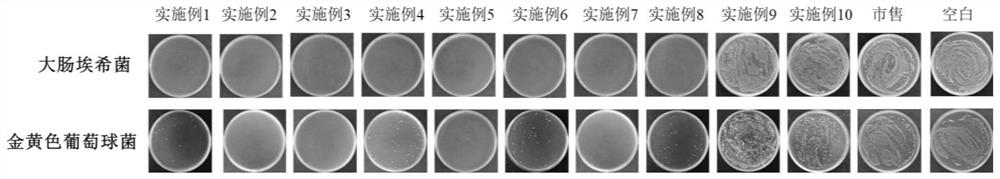

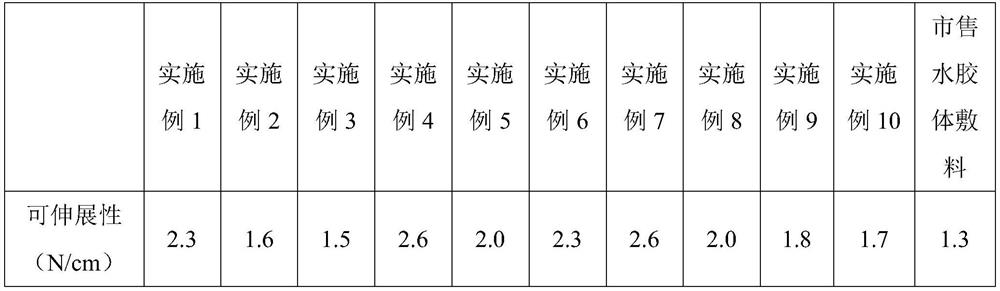

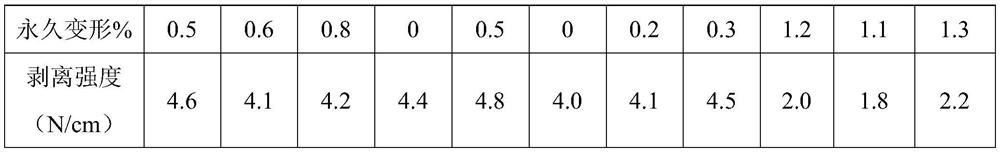

Examples

Embodiment 1

[0026] Put 10 parts of styrene-ethylene-butylene-styrene block copolymer (SEBS-YH-506), 2 parts of hyaluronic acid (molecular weight 500,000 Daltons) and 1 part of cobalt chloride at a speed of 200r / min in the internal mixer, knead at 160°C for 30 min, cool to room temperature to obtain a hydrocolloid layer; cut the polyurethane film into the size of the mold, and apply the above hydrocolloid layer on the polyurethane film in the groove of the mold, covering Glassine paper was punched and formed at 160°C and 10MPa to obtain a hydrocolloid dressing.

Embodiment 2

[0028] Place 5 parts of styrene-isoprene-styrene block copolymer (SIS-YH-1126), 2 parts of carboxylated chitosan (molecular weight 200,000 Daltons) and 4 parts of zinc chloride at a speed of In a 150r / min internal mixer, knead at 150°C for 60 minutes, cool to room temperature to obtain a hydrocolloid layer; cut the polyurethane film into the size of the mold, and apply the above hydrocolloid layer on the polyurethane film in the groove of the mold , covered with glassine paper, punched and formed at 160° C. and 10 MPa to obtain a hydrocolloid dressing.

Embodiment 3

[0030] Put 8 parts of EPDM rubber (EPDM-X-3042E), 4 parts of carboxylated starch (molecular weight 1,000,000 Daltons) and 4 parts of ferric chloride into an internal mixer with a rotation speed of 200r / min. Mix at 150°C for 5 minutes, cool to room temperature to obtain a hydrocolloid layer; cut the polyurethane film into the size of the mold, and in the groove of the mold, apply the above hydrocolloid layer on the polyurethane film, cover with glassine paper, at 150°C, Stamping under 10MPa to obtain hydrocolloid dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com