Method for preparing reduced graphene oxide load ReS2 for cathode material of lithium sulfur battery

A cathode material, lithium-sulfur battery technology, used in nanotechnology for materials and surface science, battery electrodes, lithium batteries, etc. problem, to achieve the effect of improving cycle stability, good electrical conductivity, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] rGO / ReS of the present invention 2 The preparation of graphene oxide was used as the substrate, and ReS was grown on graphene oxide by hydrothermal method. 2 At the same time, graphene oxide can be reduced, and the product obtained by hydrothermal treatment can be calcined to obtain rGO / ReS 2 composite material. In the battery system, it can be applied to the positive electrode of lithium-sulfur battery by mixing and calcining with sulfur. The specific process is as follows:

[0024] 1) Preparation of graphene oxide dispersion

[0025] Weigh 25-60 mg of commercial single-layer graphene oxide powder, add it to deionized water, the concentration of graphene oxide solution is 1.2-2 mg / ml, stir well, add 10-60 mg hexadecyl trimethyl bromide ammonium chloride (CTAB), put it into an ultrasonic cleaner for 1-4h to make it evenly dispersed, and then keep stirring for 1-4h.

[0026] 2) Preparation of reduced graphene oxide supported ReS 2 Nanosheets

[0027] Add ammonium ...

Embodiment 1

[0034] (1) Prepare graphene oxide dispersion liquid. Weigh 60 mg of commercial single-layer graphene oxide powder, add it to deionized water, so that the concentration of the graphene oxide solution is 2 mg / ml, after stirring evenly, add 40 mg cetyltrimethylammonium bromide (CTAB) , put it into an ultrasonic cleaner for 2 hours to make it dispersed evenly, and then continue to stir for 2 hours.

[0035] (2) Preparation of reduced graphene oxide supported ReS 2 Nanosheets. Weigh 30mg of ammonium perrhenate, add 60mg of thiourea to the graphene oxide dispersion prepared in step 1, stir magnetically for 3 hours to make it evenly mixed, and move the mixed solution to a stainless steel reaction kettle with a polytetrafluoroethylene liner of 50ml Then put it into a vacuum drying oven and heat it to 220°C, react for 24 hours, wait for the reaction kettle to cool down to room temperature, centrifuge to collect the reaction product in the inner tank of the reaction kettle, wash it wi...

Embodiment 2

[0041] The difference from Example 1 is: (1) preparing a graphene oxide dispersion. Weigh 60 mg of commercial single-layer graphene oxide powder, add it to deionized water to make the concentration of graphene oxide solution 2 mg / ml, after stirring evenly, put it into an ultrasonic machine for 2 h to disperse evenly, then continue stirring for 2 h . The rest are the same as in Embodiment 1, and will not be repeated here.

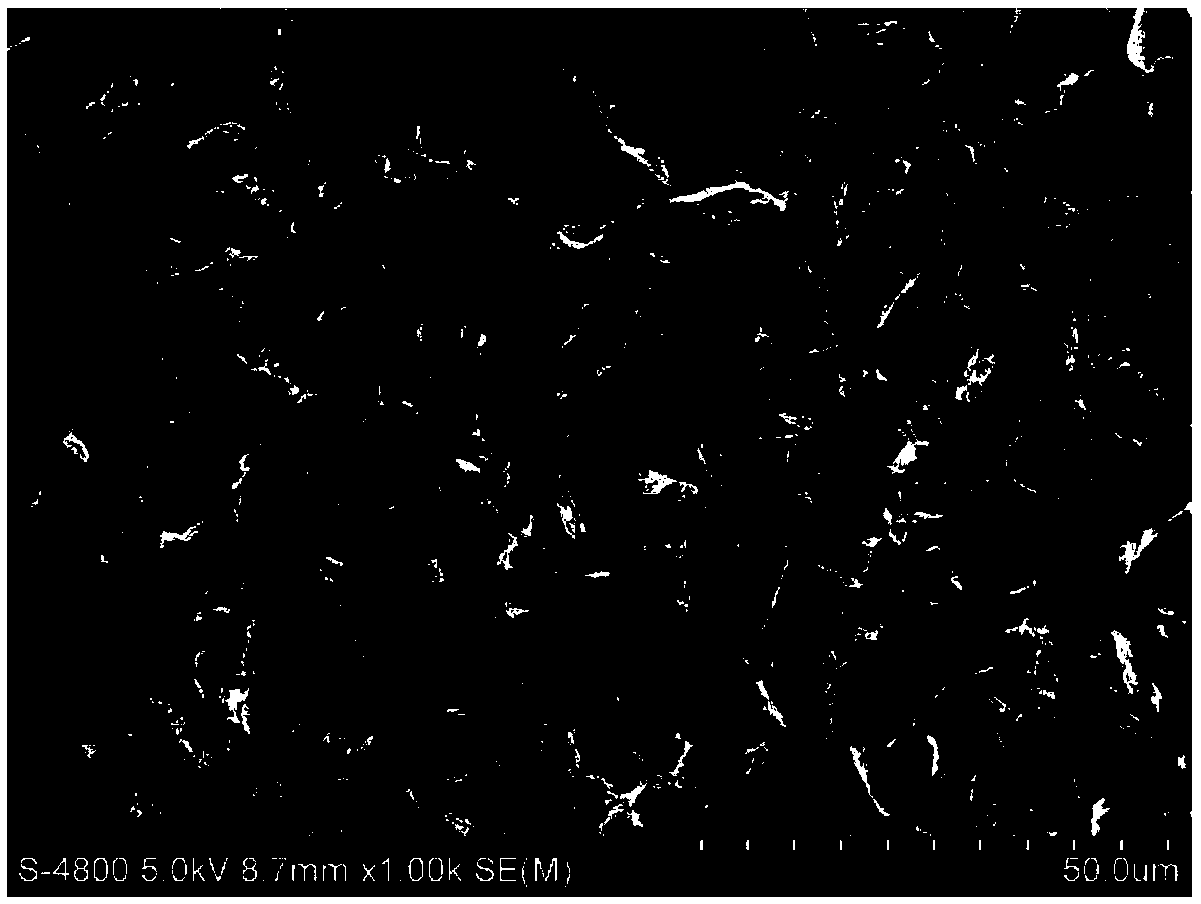

[0042] The resulting material is compared with Example 1, ReS 2 It is a nanosphere, which cannot be well combined with the reduced graphene oxide, and the distribution is uneven, which will lead to a decrease in the specific surface area of the material, slow down the reaction kinetics, and also lead to a decrease in the loading of the active substance sulfur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com