Hollow spherical ceo for lithium-sulfur battery cathode 2-x Preparation method of @c composite material

A lithium-sulfur battery and composite material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as capacity decay, loss of active material, concentration difference, etc., to accelerate electron transfer, slow down volume expansion, and inhibit dissolution and diffusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

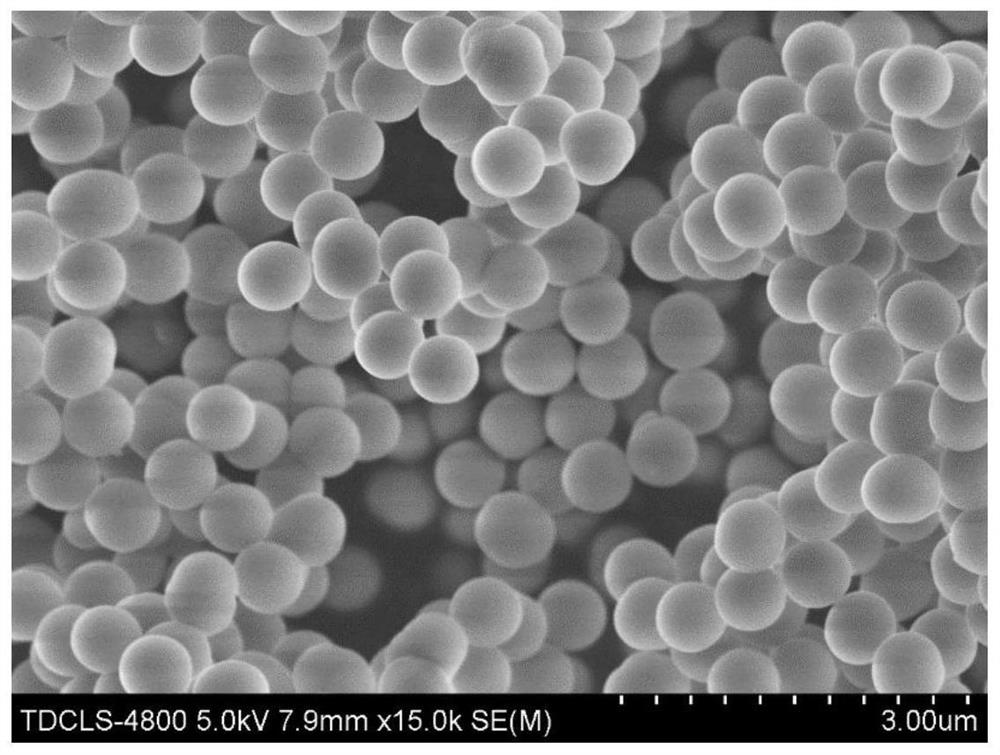

[0033] (1) Preparation of SiO 2 ball. Weigh 70mL of ammonia water and add it to 250mL of absolute ethanol, stir for 30min, add 12.6mL of tetraethyl silicate, continue to stir for 3h, collect the reaction product by centrifugation, wash with deionized water and alcohol for 3 times in turn, and dry in a vacuum oven , to obtain SiO with uniform particle size 2 nanospheres.

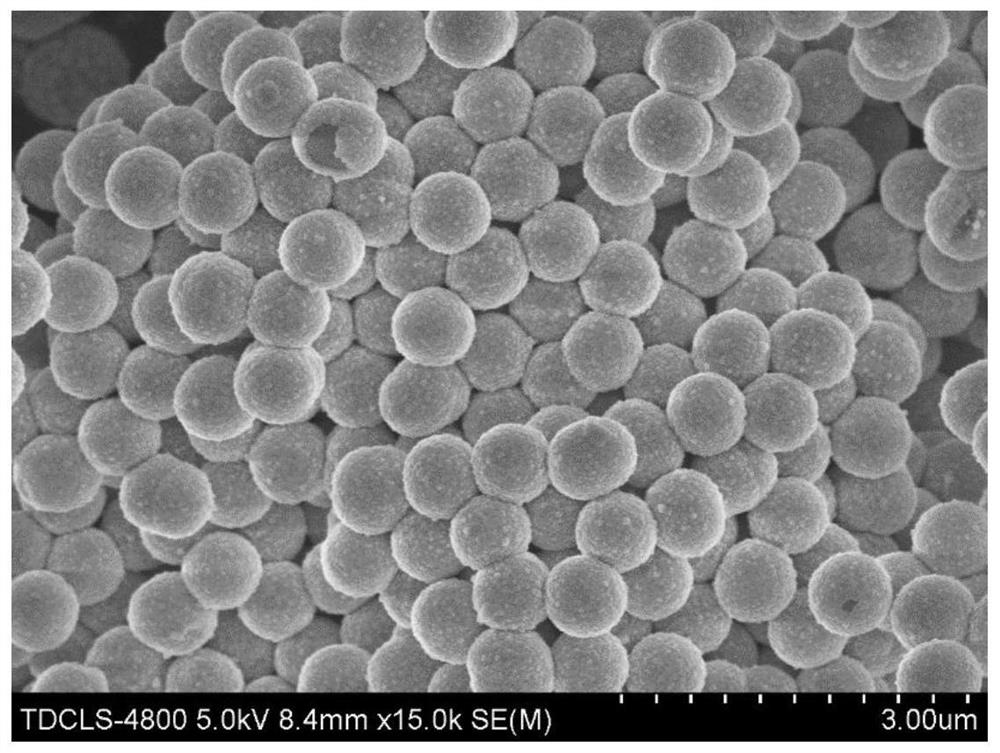

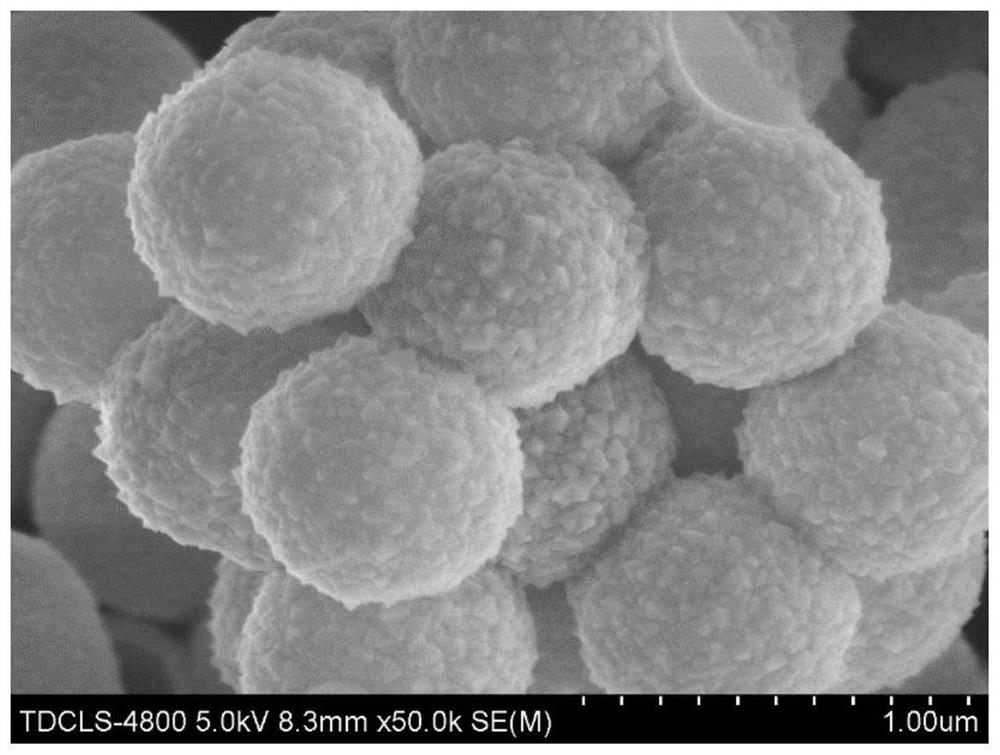

[0034] (2) Preparation of hollow CeO with oxygen vacancies2 nanospheres. Weigh 0.15g of SiO prepared in step 1 2 spheres, added to 30mL of absolute ethanol, ultrasonicated for 1h, 0.5g of urea, 2.61g of cerium nitrate hexahydrate were added to 40mL of deionized water, magnetically stirred for 30min and then added to SiO 2 In the dispersion liquid, after mixing evenly, move the mixed liquid to a 100ml stainless steel reaction kettle with a polytetrafluoroethylene liner, then put it in a vacuum drying oven and heat it to 160°C, react for 8 hours, wait for the reaction kettle to cool to room temperature, and...

Embodiment 2

[0040] Different from Example 1: (2) prepare hollow CeO 2 nanospheres. Weigh 0.15g of SiO prepared in step 1 2 spheres, added to 30mL of absolute ethanol, ultrasonicated for 1h, 0.5g of urea, 2.61g of cerium nitrate hexahydrate were added to 40mL of deionized water, magnetically stirred for 30min and then added to SiO 2 In the dispersion liquid, after mixing evenly, move the mixed liquid to a 100mL stainless steel reaction kettle with a polytetrafluoroethylene liner, then put it in a vacuum drying oven and heat it to 160°C, react for 8 hours, wait for the reaction kettle to cool to room temperature, and filter with suction Collect the reaction product in the inner tank of the reactor, wash it with deionized water and alcohol in turn, and obtain CeO after drying in an oven. 2 coated SiO 2 Ball, add the product to 1mol / L NaOH solution, let stand at 50°C for 10h, etch away SiO 2 Template, the product was collected by suction filtration, washed with deionized water and alcohol...

Embodiment 3

[0044] (1) Preparation of SiO 2 ball. Weigh 70mL of ammonia water and add it to 250mL of absolute ethanol, stir for 30min, add 12.6mL of tetraethyl silicate, continue to stir for 3h, collect the reaction product by centrifugation, wash with deionized water and alcohol for 3 times in turn, and dry in a vacuum oven , to obtain SiO with uniform particle size 2 nanospheres.

[0045] (2) Preparation of hollow CeO 2 nanospheres. Weigh 0.15g of SiO prepared in step 1 2 spheres, added to 30mL of absolute ethanol, ultrasonicated for 1h, 0.5g of urea, 2.61g of cerium nitrate hexahydrate were added to 40mL of deionized water, magnetically stirred for 30min and then added to SiO 2 In the dispersion liquid, after mixing evenly, move the mixed liquid to a 100ml stainless steel reaction kettle with a polytetrafluoroethylene liner, then put it in a vacuum drying oven and heat it to 160°C, react for 8 hours, wait for the reaction kettle to cool to room temperature, and filter with suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com