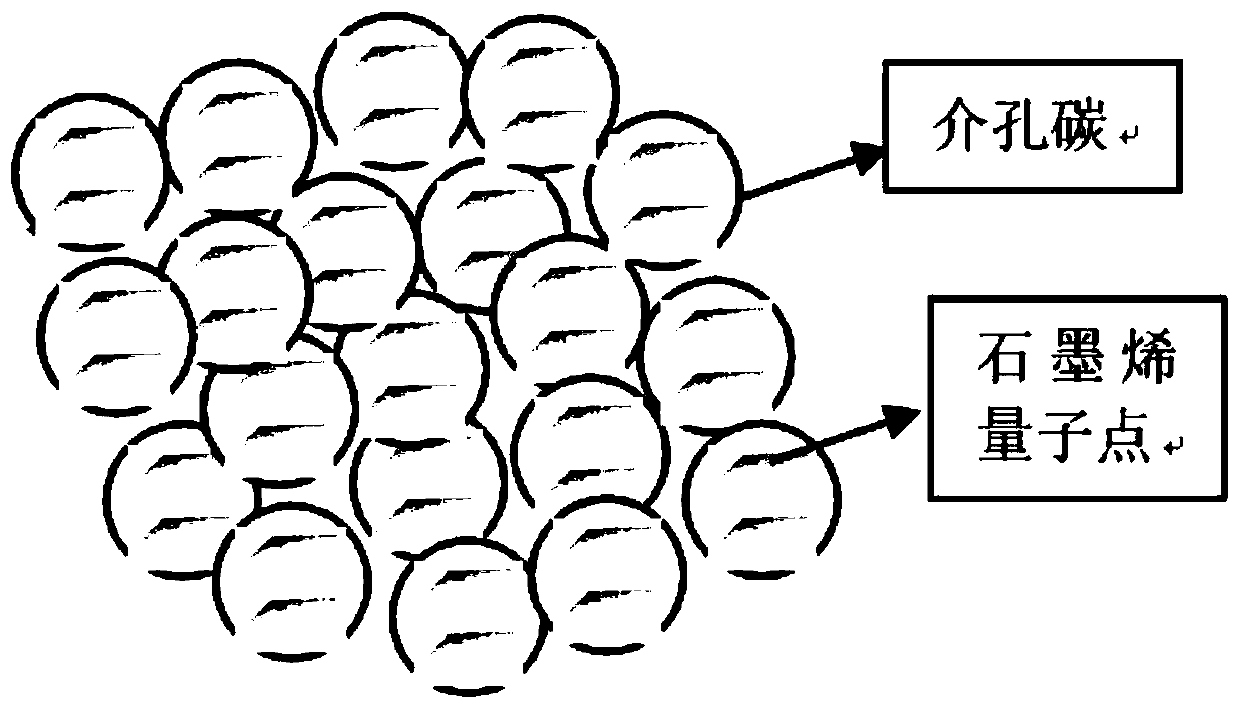

Preparation method and application of a graphene quantum dot/mesoporous carbon composite material

A technology of graphene quantum dots and composite materials, applied in the field of preparation, graphene quantum dots/mesoporous carbon composite materials, can solve problems such as intermediate product shuttle effect, sulfur volume strain, poor sulfur conductivity, etc., and achieve good conductivity, High theoretical specific capacity and favorable transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a kind of preparation method of graphene quantum dot / mesoporous carbon composite material, it is characterized in that, comprises the following steps:

[0026] A) mixing and stirring the aqueous solution of resole phenolic resin and a surfactant, and performing a heating reaction to obtain a surfactant-phenolic single micelle solution, wherein the surfactant is selected from F127 or P123;

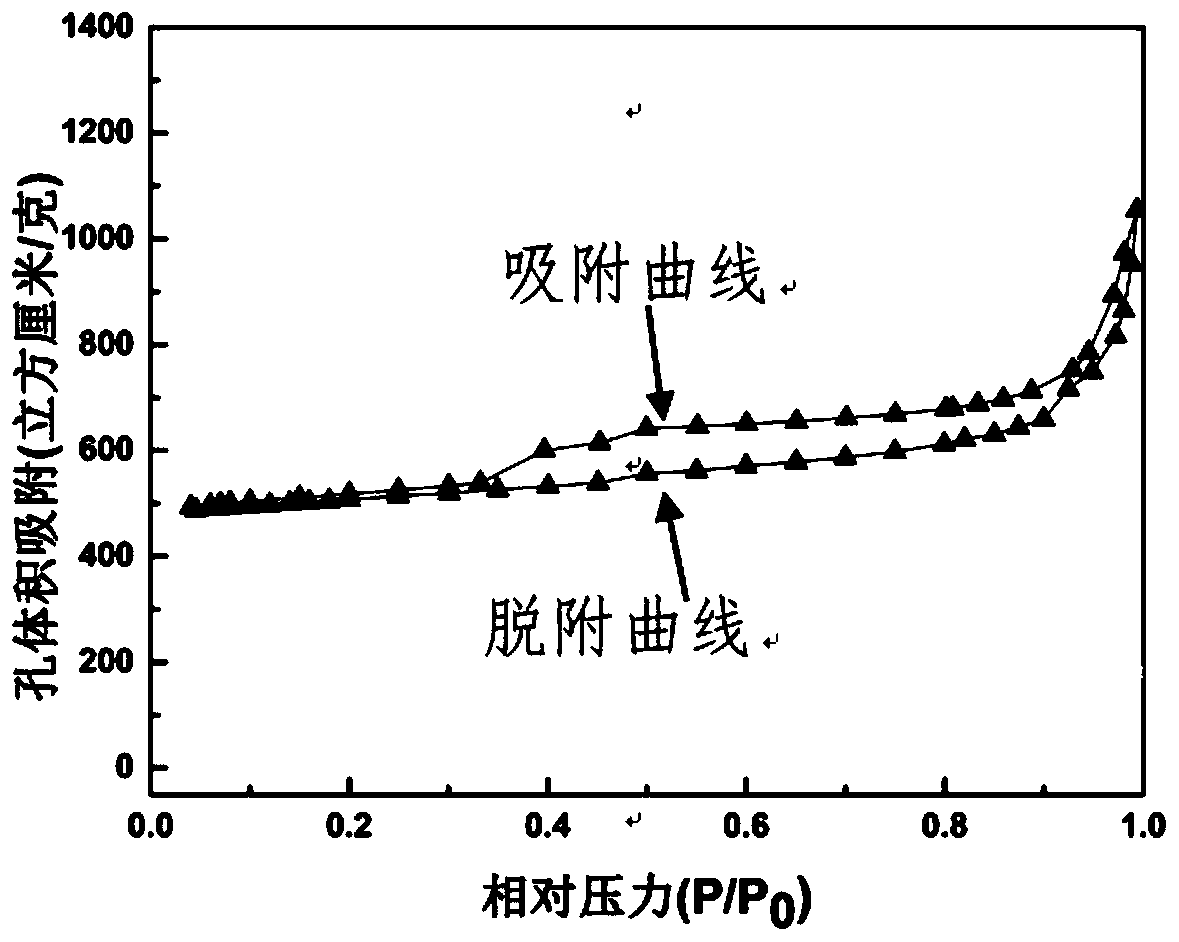

[0027] B) Mix the graphene quantum dot aqueous solution with the step A) surfactant-phenolic single micelle solution, then carry out hydrothermal reaction at 130°C-180°C for 20h-30h, and the reaction product is freeze-dried and then annealed at high temperature, carbonized, cleaned and After drying, the graphene quantum dot / mesoporous carbon composite material is obtained.

[0028] The present invention uses graphene quantum dots and surfactant-phenolic single micelles as raw materials to prepare composite materials. In the present invention, the g...

Embodiment 1

[0065] F127-phenolic single micellar solution was obtained by aqueous phase synthesis. The details are as follows: Dissolve phenol at 40°C, keep magnetic stirring, slowly add NaOH aqueous solution, then add formalin aqueous solution drop by drop, control the molar ratio of the four, phenol: formaldehyde: NaOH: H 2 O is 2.1:10:0.5:580. Stirring at 70°C for 0.5h, a low molecular weight resole phenolic resin was obtained. Then add F127, control the molar ratio of F127 and phenolic resin to 0.035, continue to stir the obtained mixed solution at 70°C for 2 hours, add 50mL of deionized water to dilute, continue heating at 70°C for 12h to obtain dark red F127-phenolic resin Beam solution.

[0066] Graphene quantum dots adopt the following method: First, weigh 1.5g of glucose, add 10m deionized water to the polytetrafluoroethylene liner of the 50mL reactor to dissolve, and stir evenly with a glass rod; slowly inject 10mL of concentrated sulfuric acid, and at the same time use a glas...

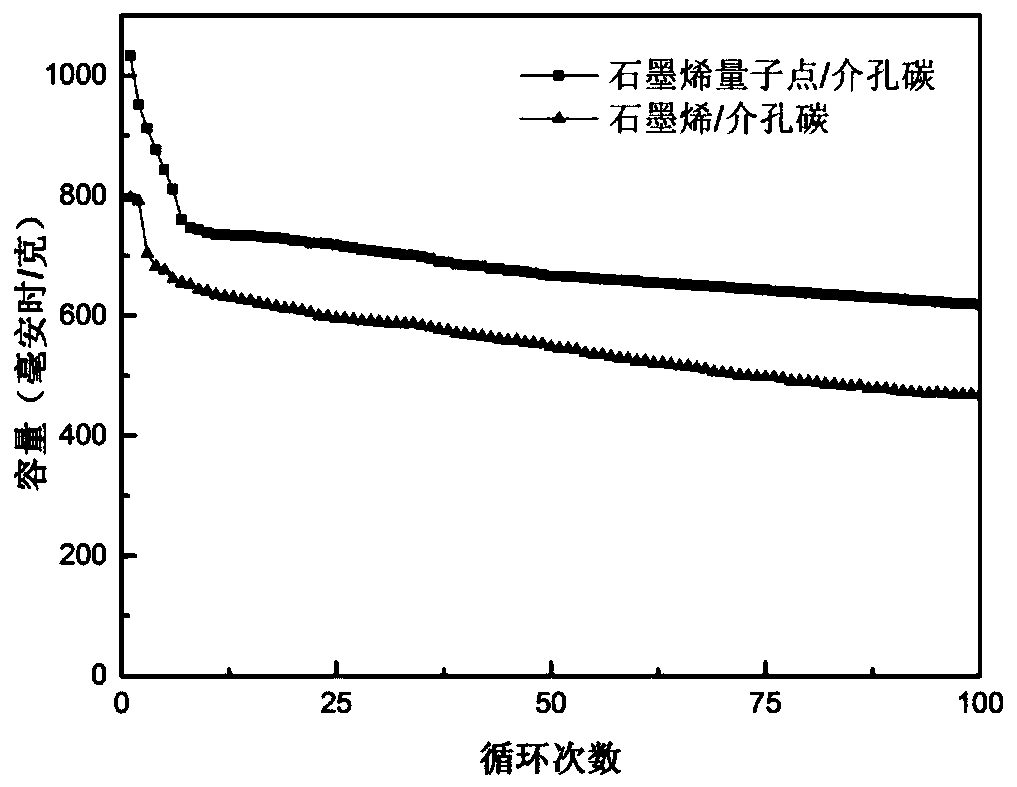

Embodiment 2

[0079] Change the 65mL 0.05mol / L pre-dispersed graphene quantum dot aqueous solution in embodiment 1 into 65mL0.25mol / L pre-dispersed graphene quantum dot aqueous solution, stir and seal in the polytetrafluoroethylene lining of 100mL In a stainless steel reaction kettle, heat water at 130°C for 20h. The graphene quantum dots and resole phenolic resin ratios are respectively 1:100 graphene quantum dots / mesoporous carbon composite material precursor. The precursor was annealed at 400°C for 2h, after removing the surfactant F127, and then carbonized at 700°C for 3h to obtain a graphene quantum dot / mesoporous carbon composite material, in which graphene quantum dots and mesoporous carbon The mass ratio of carbon is 1:60. . Dissolve 1.2 g of 2 S and the graphene / mesoporous carbon composite material obtained in Comparative Example 1 of 0.8g were mixed, and left standing at room temperature for one day to be treated by CS 2 After the volatilization is complete, seal it and put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com