Method for forming channel hole of three-dimensional memory

A memory and channel technology, used in semiconductor devices, electrical solid-state devices, electrical components, etc., can solve the problems of too large CD of deep-hole channel holes, reduced distance between holes and too large top key size, etc. , to achieve the effect of good top width, reduced pattern size, and reduced etching difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the method for forming the channel hole of the three-dimensional memory provided by the present invention will be described in detail below with reference to the accompanying drawings.

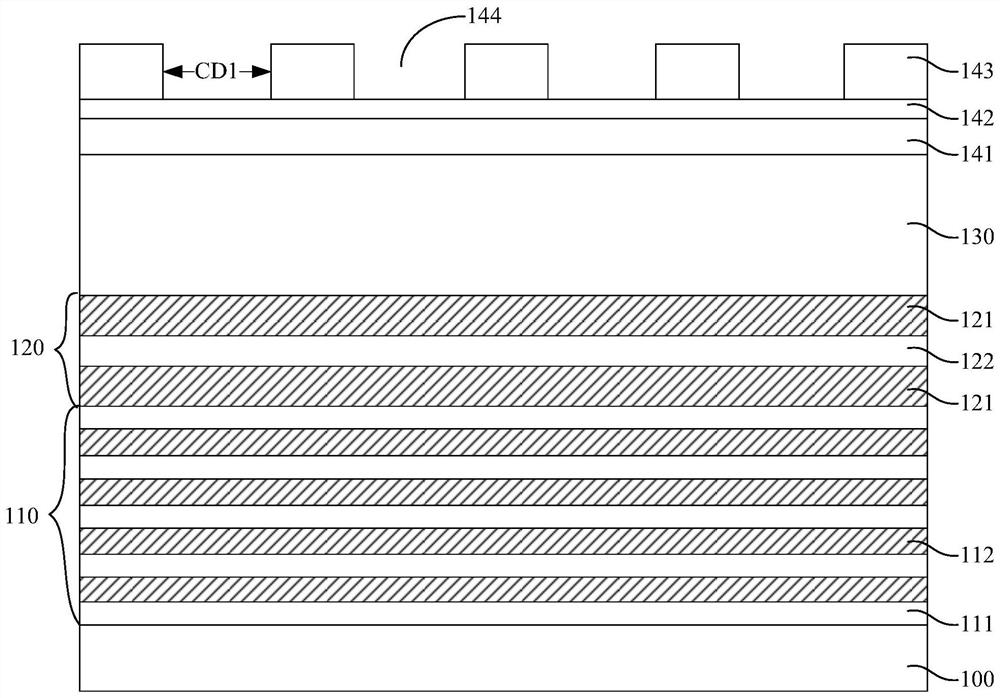

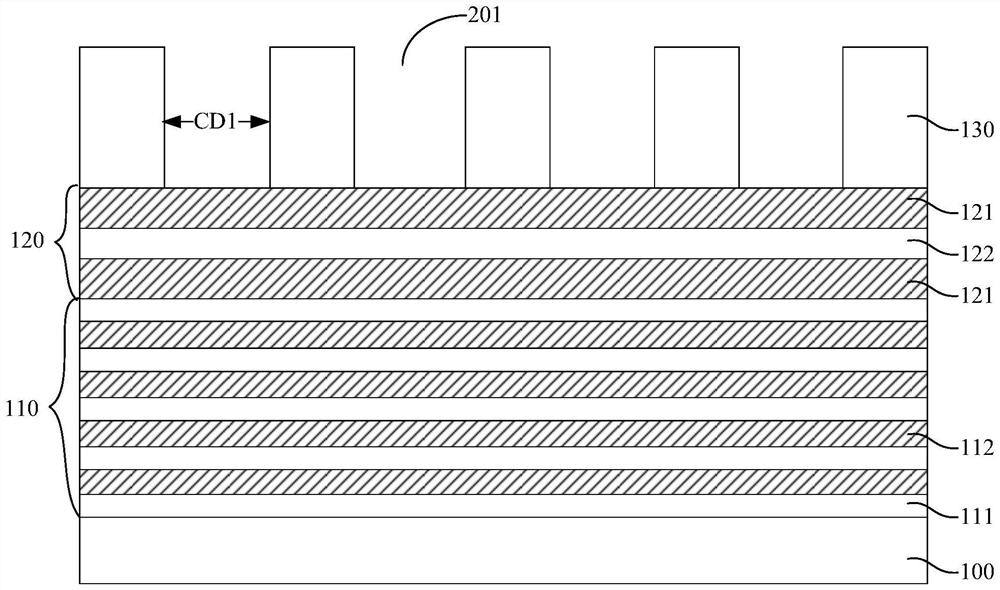

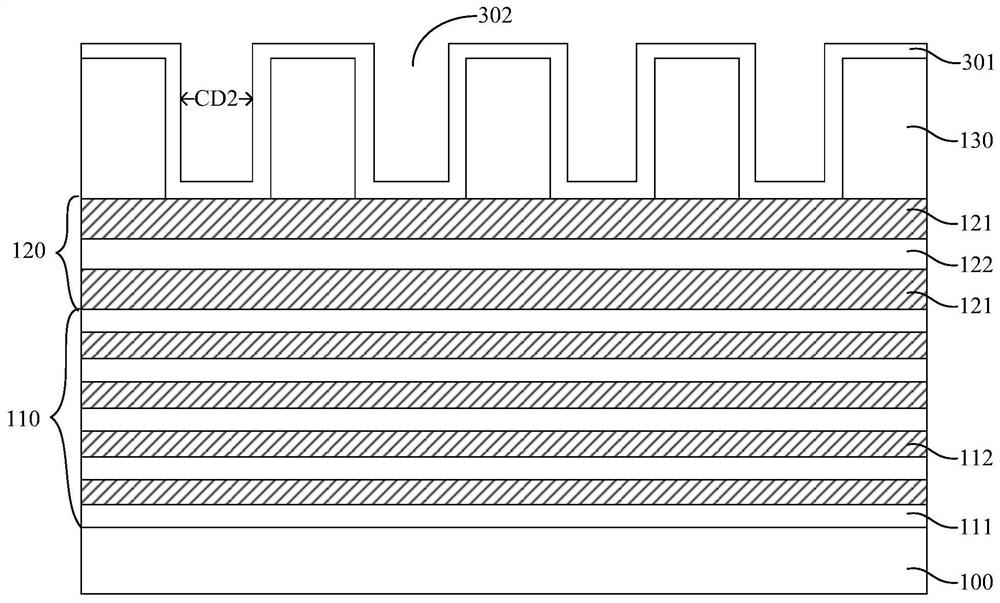

[0019] Please refer to Figure 1 to Figure 7 It is a structural schematic diagram of the formation process of the channel hole of the three-dimensional memory according to a specific embodiment of the present invention.

[0020] Please refer to figure 1 1. A substrate 100 is provided, the surface of the substrate 100 has a stacked structure; a mask layer 130 is formed on the stacked structure.

[0021] The substrate 100 can be a single crystal silicon substrate, a Ge substrate, a SiGe substrate, SOI or GOI, etc.; according to the actual requirements of the device, a suitable semiconductor material can be selected as the substrate 100, which is not limited here. In this specific implementation manner, the substrate 100 is a single crystal silicon wafer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com