Method for preparing metal 1T phase rhenium sulfide hollow nanosphere supercapacitor electrode material

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, nanotechnology, nanotechnology, etc., can solve problems such as poor electrical conductivity, and achieve the effects of low cost, good internal porous structure, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mix 36 mL of absolute ethanol, 120 mL of water, and 1.5 mL of ammonia water (25%~28% in mass concentration) and stir for 45 minutes, then add 1.5 mL of ethyl orthosilicate, continue stirring for 15 minutes, and then add 0.6 g of dopamine hydrochloride, stirred for 32 hours, centrifugally dried, calcined at 800°C for 3 hours, dispersed the calcined solid in a hydrofluoric acid solution with a mass concentration of 10%, soaked in a water bath at 60°C for 24h, filtered, and deionized water Hollow carbon spheres are obtained after washing and drying;

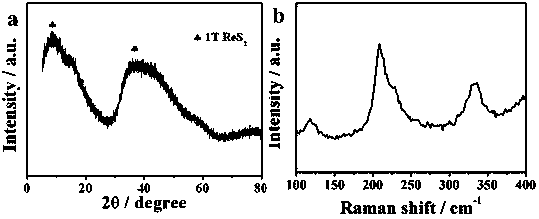

[0029] (2) Disperse 50 mg of hollow carbon spheres in 50 mL of absolute ethanol, add 0.2 g of ammonium perrhenate, 0.2 g of L-cysteine, and 0.05 g of CTAB, conduct a hydrothermal reaction at 180 °C for 24 hours, and then dry by centrifugation. The metal 1T phase hollow rhenium sulfide nanospheres were obtained.

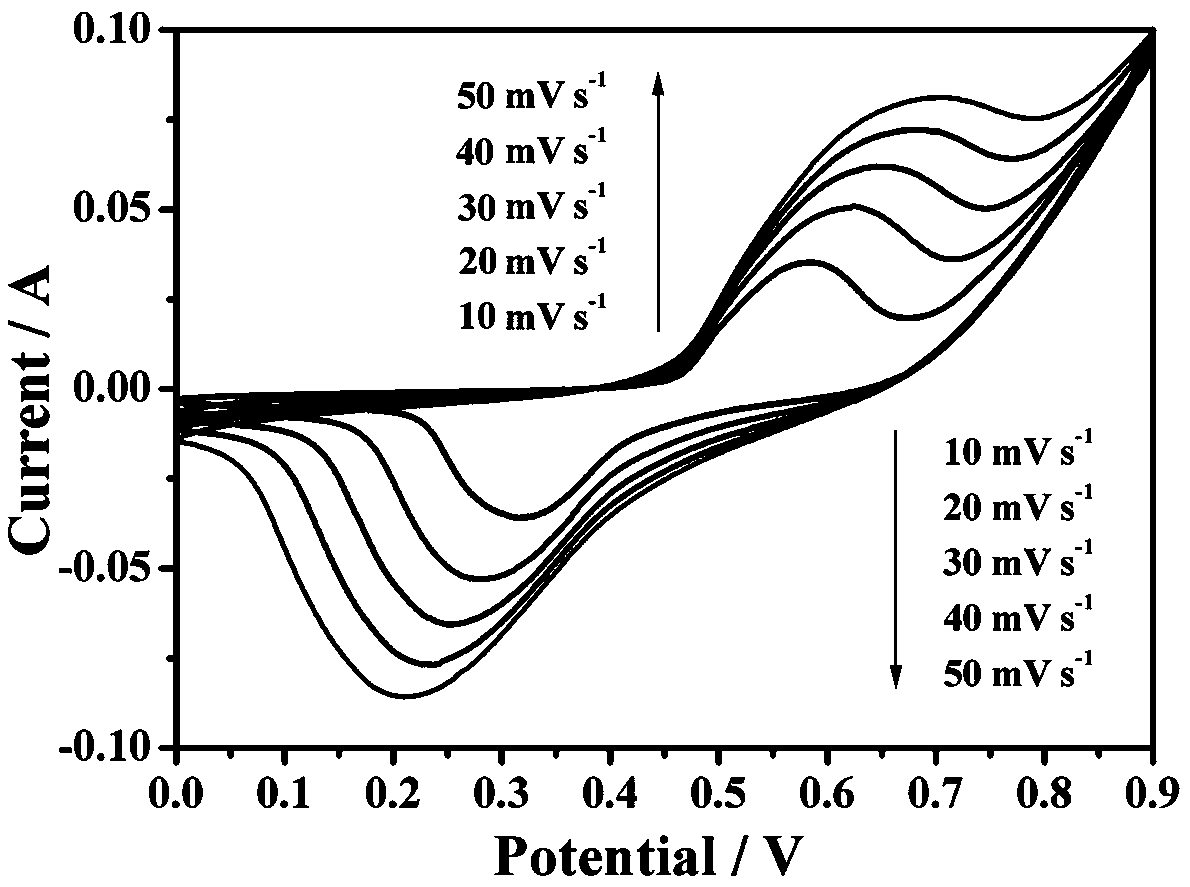

[0030] Performance tests were performed on the metal 1T phase rhenium sulfide hollow nanosphere supercapacito...

Embodiment 2

[0038](1) Mix 36 mL of absolute ethanol, 120 mL of water, and 1.5 mL of ammonia water (25%~28% in mass concentration) and stir for 45 minutes, then add 1.5 mL of ethyl orthosilicate, continue stirring for 15 minutes, and then add 0.6 g of dopamine hydrochloride, stirred for 32 hours, centrifugally dried, calcined at 800°C for 3 hours, dispersed the calcined solid in a hydrofluoric acid solution with a mass concentration of 10%, soaked in a water bath at 60°C for 24h, filtered, and deionized water Hollow carbon spheres are obtained after washing and drying;

[0039] (2) Disperse 30 mg of hollow carbon spheres in 50 mL of absolute ethanol, add 0.2 g of ammonium perrhenate, 0.2 g of L-cysteine, and 0.05 g of CTAB, conduct a hydrothermal reaction at 180 °C for 24 hours, and then centrifuge and dry. The metal 1T phase hollow rhenium sulfide nanospheres were obtained.

[0040] Performance tests were performed on the metal 1T phase rhenium sulfide hollow nanosphere supercapacitor el...

Embodiment 3

[0047] (1) Mix 36 mL of absolute ethanol, 120 mL of water, and 1.5 mL of ammonia water (25%~28% in mass concentration) and stir for 45 minutes, then add 1.5 mL of ethyl orthosilicate, continue stirring for 15 minutes, and then add 0.6 g of dopamine hydrochloride, stirred for 32 hours, centrifugally dried, calcined at 800°C for 3 hours, dispersed the calcined solid in a hydrofluoric acid solution with a mass concentration of 10%, soaked in a water bath at 60°C for 24h, filtered, and deionized water After washing and drying, hollow carbon spheres are obtained.

[0048] (2) Disperse 70 mg of hollow carbon spheres in 50 mL of absolute ethanol, add 0.2 g of ammonium perrhenate, 0.2 g of L-cysteine, and 0.05 g of CTAB, conduct a hydrothermal reaction at 180 °C for 24 hours, and then centrifuge and dry. The metal 1T phase hollow rhenium sulfide nanospheres were obtained.

[0049] Performance tests were performed on the metal 1T phase rhenium sulfide hollow nanosphere supercapacitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com