SPR (Surface Plasmon Resonance) sensor made with graphene/gold/D-type plastic optical fiber and preparation method thereof

A technology of plastic optical fiber and graphene, which is applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve the problems such as difficult to grow graphene structure, achieve the effect of improving chemical stability, improving sensitivity and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

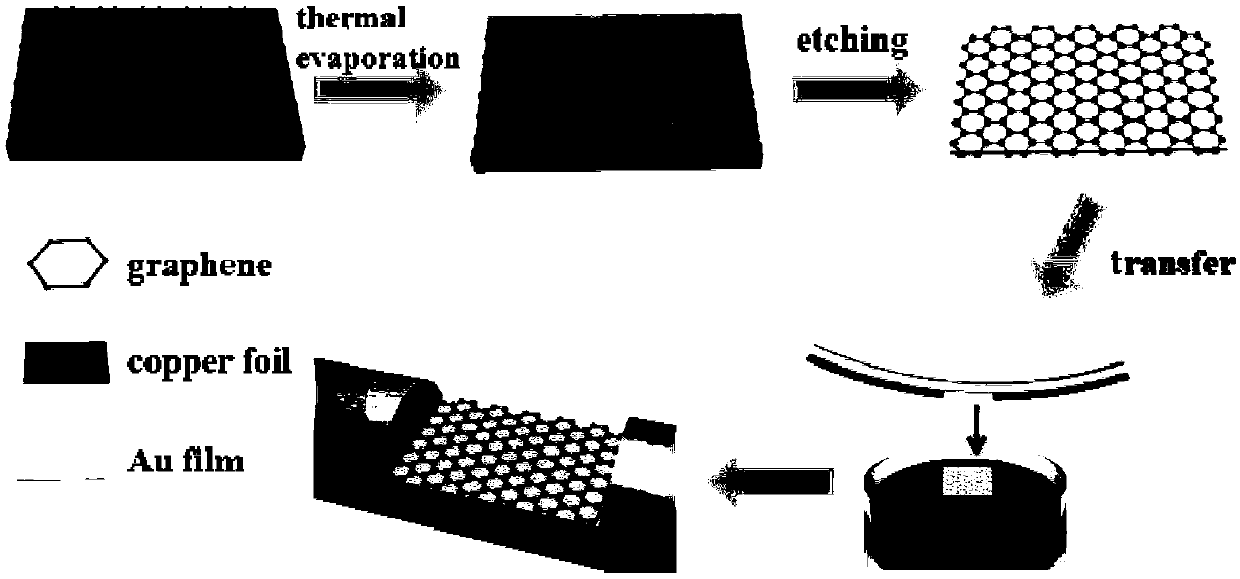

[0040] A preparation method of graphene / gold / D-type plastic optical fiber SPR sensor, comprising the following preparation steps:

[0041] (1) Make D-type optical fiber: a section of 15cm plastic optical fiber (material is PMMA) with a diameter of 1 micron, remove the fiber cladding and part of the core in the sensing area by side polishing method, and open a length of 1cm, depth Groove-shaped sensing area 30% of fiber diameter. The D-type sensing area is then rinsed with deionized water to remove impurities;

[0042] (2) growth graphene: the copper foil after polishing is put into tube furnace, by passing into the mixed gas of the hydrogen of 50sccm and 50sccm methane in tube furnace, keep 30min under 1000 °, graphene layer number is monolayer, then cut the graphene / copper foil into small rectangular stripes (1.2cm×0.5cm);

[0043] (3) The gold film is directly thermally evaporated onto the graphene: put a 7.5cm high-purity gold wire into a molybdenum boat (length: 100mm, w...

Embodiment 2

[0046] A preparation method of graphene / gold / D-type plastic optical fiber SPR sensor, comprising the following preparation steps:

[0047] (1) Make D-shaped optical fiber: a section of 15cm plastic optical fiber (material is PMMA) with a diameter of 1 micron, remove the fiber cladding and part of the core in the sensing area by side polishing, and open a length of 2cm, depth Groove-shaped sensing area 45% of fiber diameter. The D-type sensing area is then rinsed with deionized water to remove impurities;

[0048] (2) growth graphene: the copper foil after polishing is put into tube furnace, by passing into the mixed gas of the hydrogen of 60sccm and 40sccm methane in tube furnace, keep 30min under 1000 °, graphene layer number is 3 layers, then cut the graphene / copper foil into small rectangular stripes (2cm×0.5cm);

[0049] (3) Gold film is directly thermally evaporated onto graphene: put 8.5cm high-purity gold wire into a molybdenum boat (100mm in length, 10mm in width, an...

Embodiment 3

[0052] A preparation method of graphene / gold / D-type plastic optical fiber SPR sensor, comprising the following preparation steps:

[0053] (1) Make a D-type optical fiber: a section of 15cm, a plastic optical fiber (material is PMMA) with a diameter of 1 micron, remove the fiber cladding and part of the core in the sensing area by side polishing, and set a length of 1.2cm, Groove-shaped sensing zone with a depth of 20% of the fiber diameter. The D-type sensing area is then rinsed with deionized water to remove impurities;

[0054] (2) growth graphene: the copper foil after polishing is put into tube furnace, by passing into the mixed gas of the hydrogen of 50sccm and 50sccm methane in tube furnace, keep 30min under 1000 °, graphene layer number is monolayer, then cut the graphene / copper foil into small rectangular stripes (1.2cm×0.5cm);

[0055] (3) Gold film is directly thermally evaporated onto graphene: put 6.5cm high-purity gold wire into molybdenum boat (length 100mm, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com