Mineral aggregate mechanized continuous production method

A production method and technology of mineral materials, which are applied in the field of underground mining of hard materials, can solve the problems that cannot meet the requirements of modern mines and refining systems, the dilution rate of mineral materials remains high, and cannot guarantee safe mining, etc., so as to achieve economical efficiency Mining, saving refining costs, and solving the effects of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention discloses a method for mechanized continuous production of ore materials, which comprises the following steps:

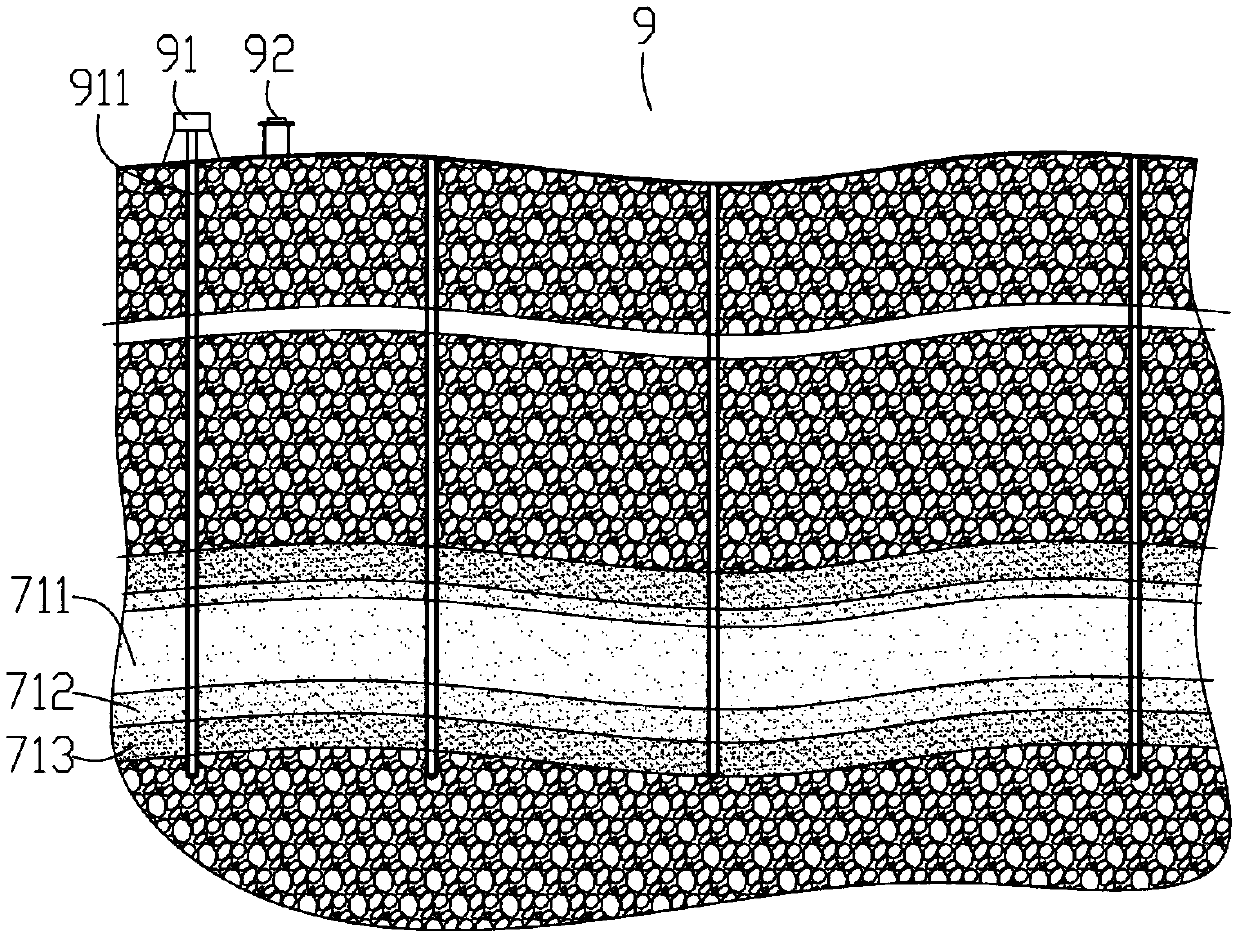

[0029] a) Exploring the area where the ore body to be mined is carried out on the ground, forming an underground ore layer model, and obtaining data on the distribution of mineral grades;

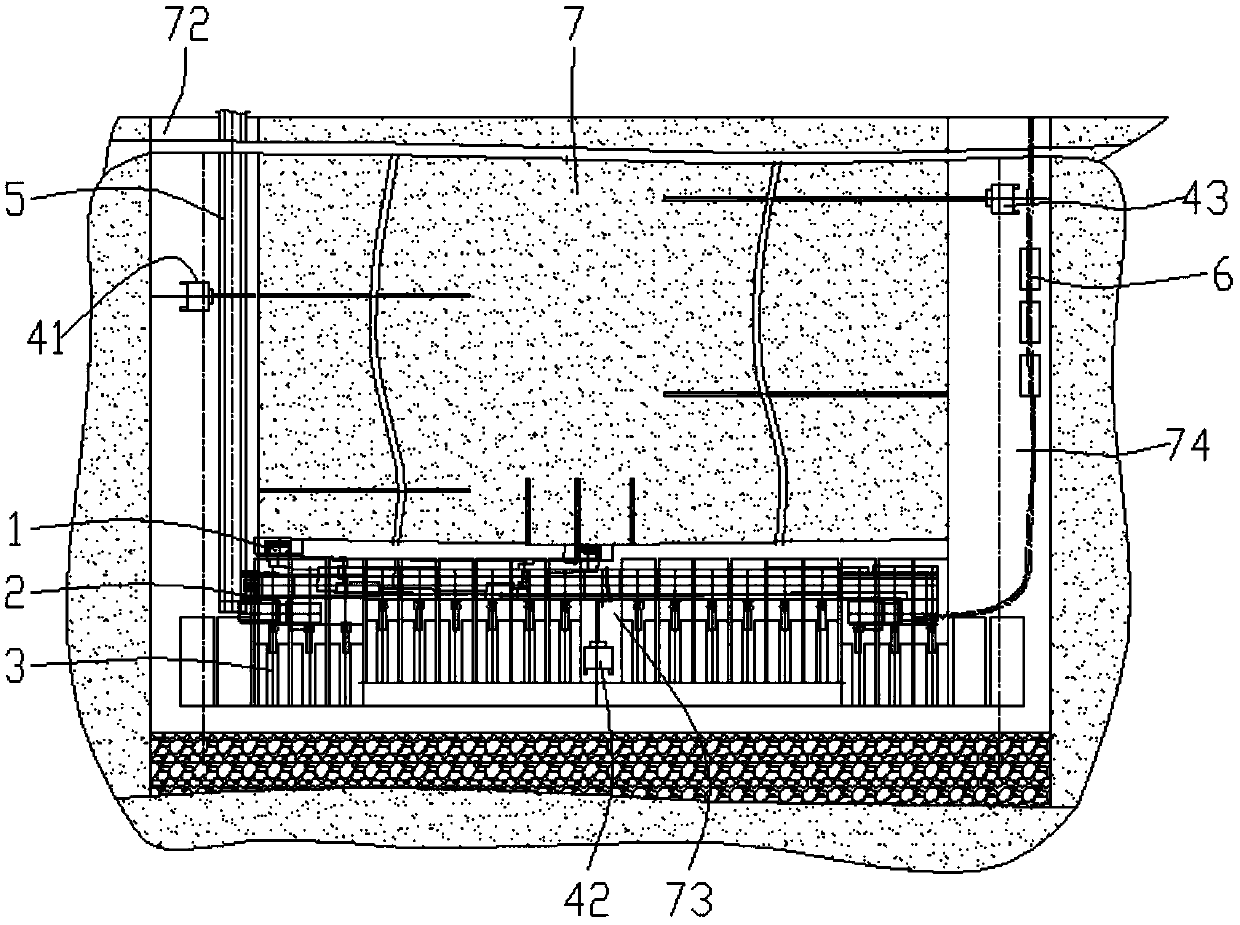

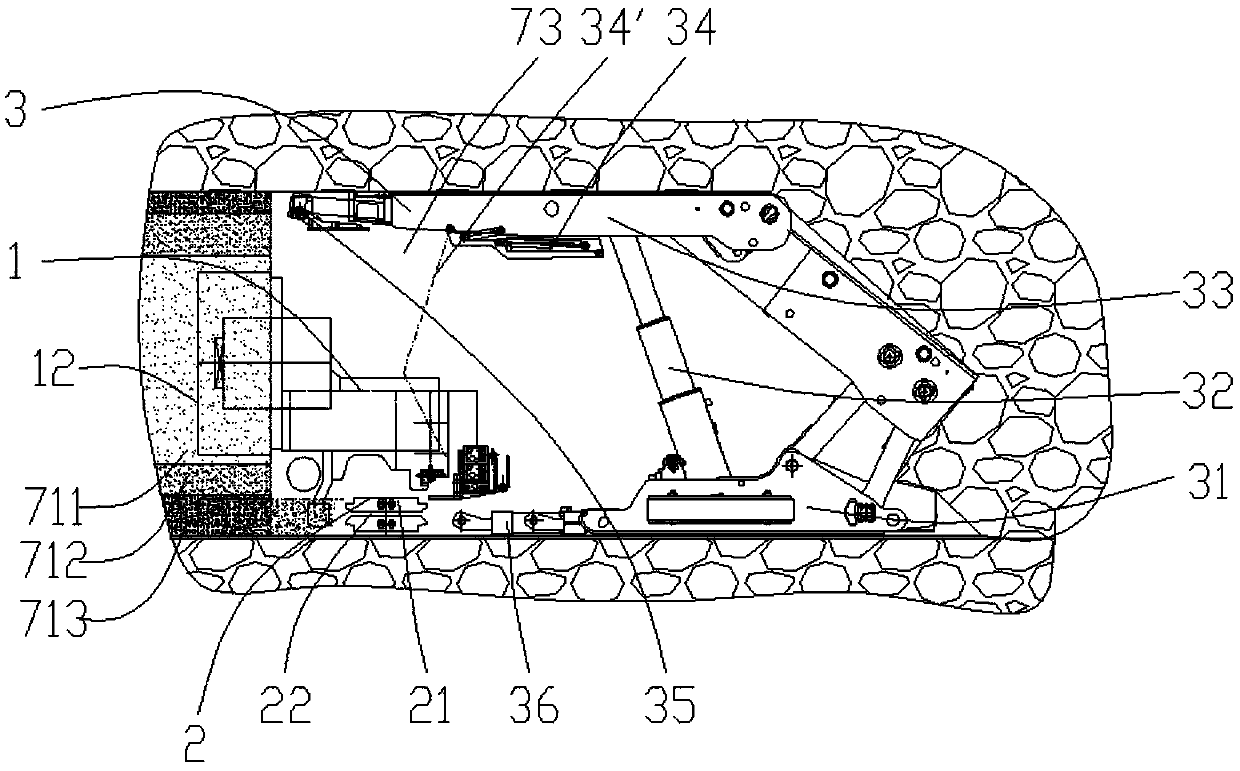

[0030] b) Determine the main parameters of the mineral material mining equipment, which at least includes a drum mining machine 1, a working face conveyor 2 and a support frame 3 (see figure 2 , 3 );

[0031] c) Digging mines and laying out supporting mining equipment;

[0032] d) Continuous mining is carried out.

[0033] The core of the method is: in the step d), divide different ore layers on the mining wall of the working face according to the grade of the ore material, and use a mining machine to mine the ore wall of the working face according to the grade of the mineral material from high to high Mining the ore layer by layer in the order of lowest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com