Replaceable energy consumption connecting node of assembly-type rectangular steel pipe column-H-type steel beam

A technology of rectangular steel pipes and connection nodes, which is applied in the direction of building types, protected buildings/shelters, building components, etc., can solve problems such as unfavorable earthquake resistance and post-earthquake repairs, lower bearing capacity, weakened column sections, etc., to prevent single Insufficient anchorage of high-strength bolts to lock, enhance the overall mechanical performance, and prevent local buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

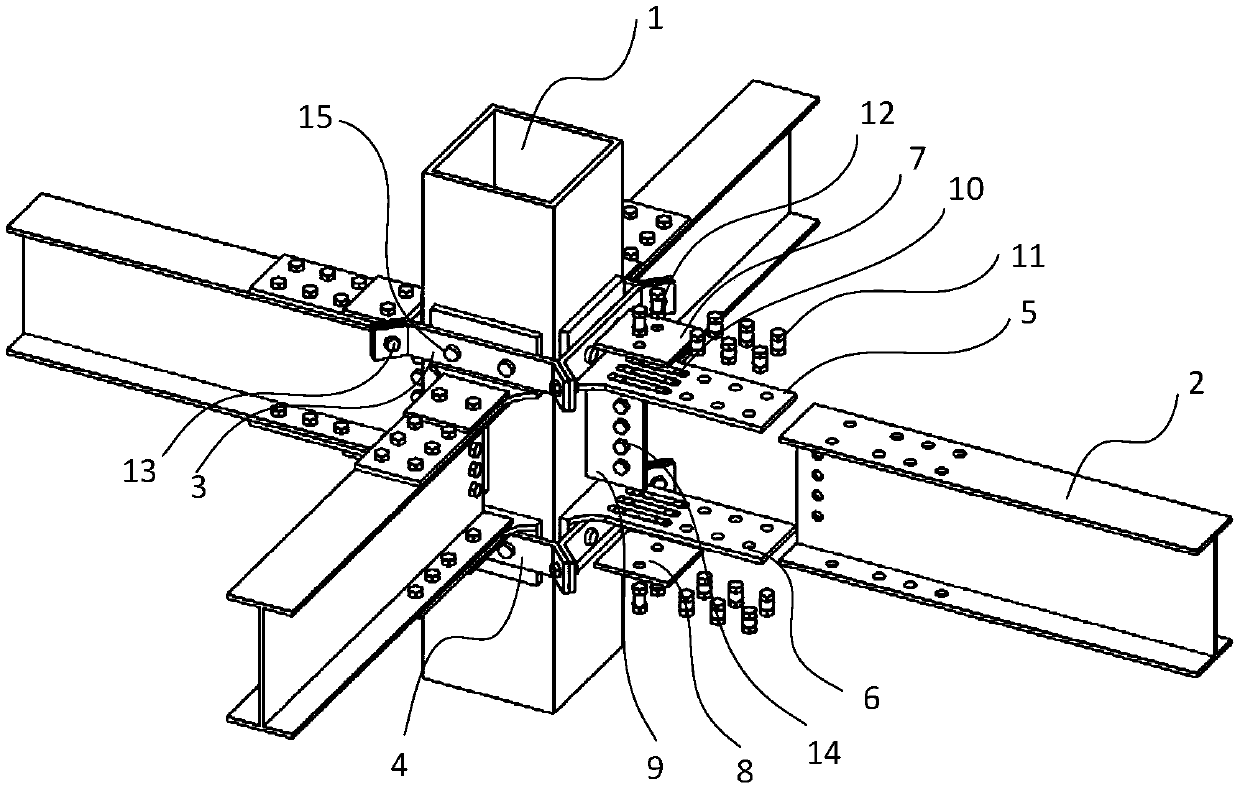

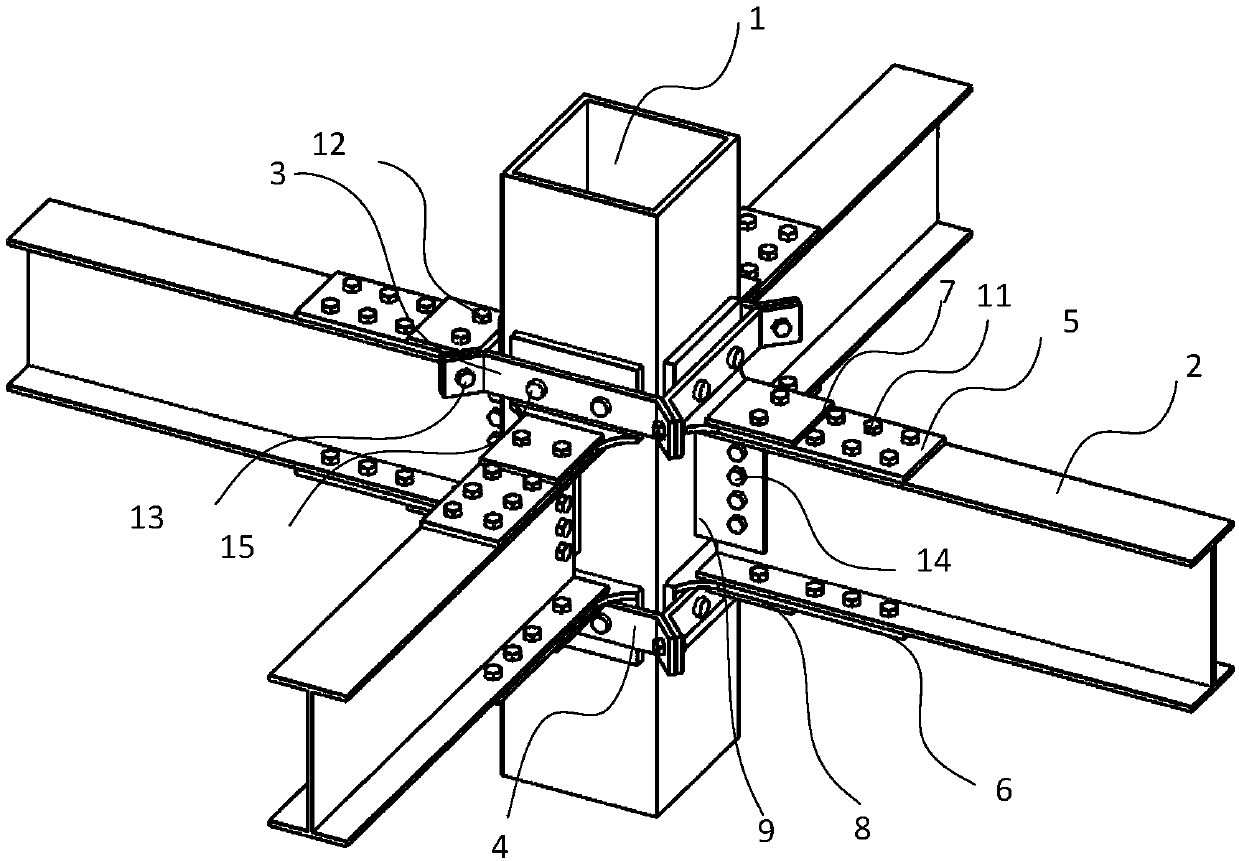

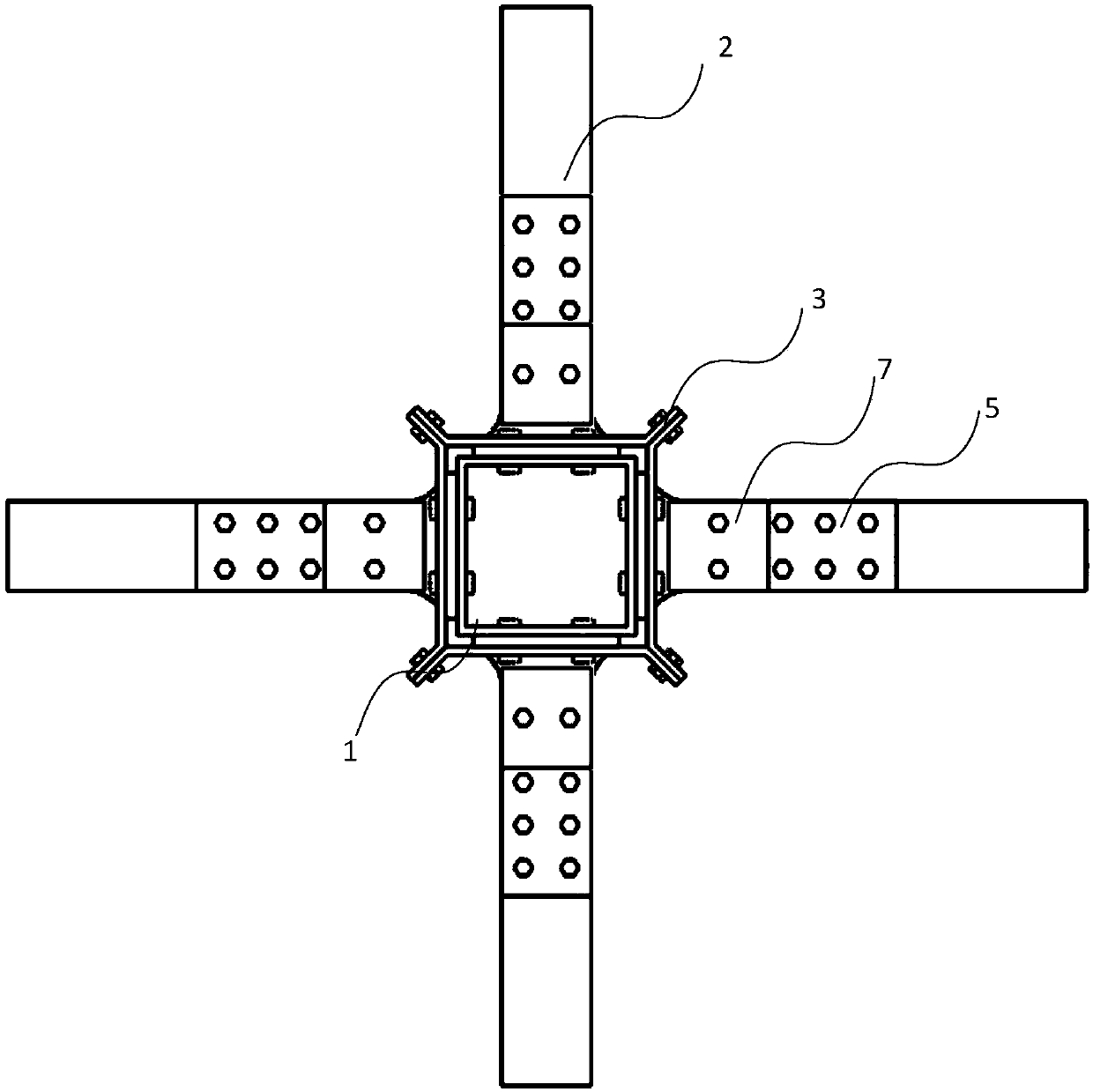

[0042] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0043] like Figure 1 to Figure 15 As shown, an assembled rectangular steel pipe column-H-shaped steel beam replaceable energy-dissipating connection node includes a rectangular steel pipe column 1, an H-shaped steel beam 2, and replaceable energy-dissipating connection force transmission components.

[0044] The rectangular steel pipe column 1 is a welded box-shaped composite section column, wherein the rectangular steel pipe column 1 is pre-welded by steel wall panels 1a, steel wall panels 1b, steel wall panels 1c and steel wall panels 1d according to a certain welding sequence.

[0045] The replaceable energy-dissipating connection force-transmitting parts include an upper unequal limb angle steel energy-dissipating connector 5, a lower un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com