Large-size titanium alloy structure micro-arc oxidation based on scanning cathode and verification method

A micro-arc oxidation, large-scale technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of reducing corrosion resistance fatigue performance, complicated process control, poor wear resistance, etc., and achieve the goal of reducing mechanical properties impact, broad application prospects, and the effect of promoting high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The specific implementation manner of the present invention will be described in detail in conjunction with the summary of the invention and the accompanying drawings.

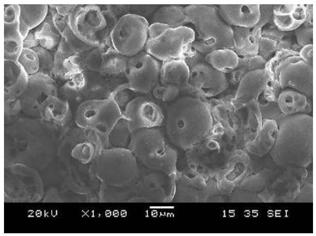

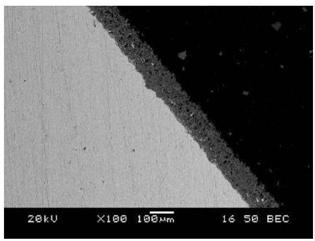

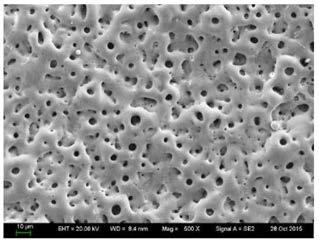

[0048] The micro-arc oxidation method of large-scale titanium alloy structure based on scanning cathode established in the patent of the present invention, the main research contents include: scanning cathode device design, scanning cathode micro-arc oxidation process research, micro-arc oxidation film thickness characteristics research and large-scale Experimental verification study of micro-arc oxidation of titanium alloy.

[0049] a) Scanning cathode device design

[0050] Design two scanning cathodes with different structures, closed and semi-closed, carry out the influence of scanning cathode structure on micro-arc oxidation, and optimize the scanning cathode structure.

[0051] 1) Effect of closed scanning cathode on micro-arc oxidation

[0052] In order to prevent the loss of the electric field,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com