A device for optical fiber side coating

A technology of side coating and optical fiber, which is applied in the field of coating devices, can solve the problems of difficult uniform distribution, time-consuming, uneven coating thickness, etc., and achieve the effect of low requirements for external conditions, simple mechanical structure, and expansion possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

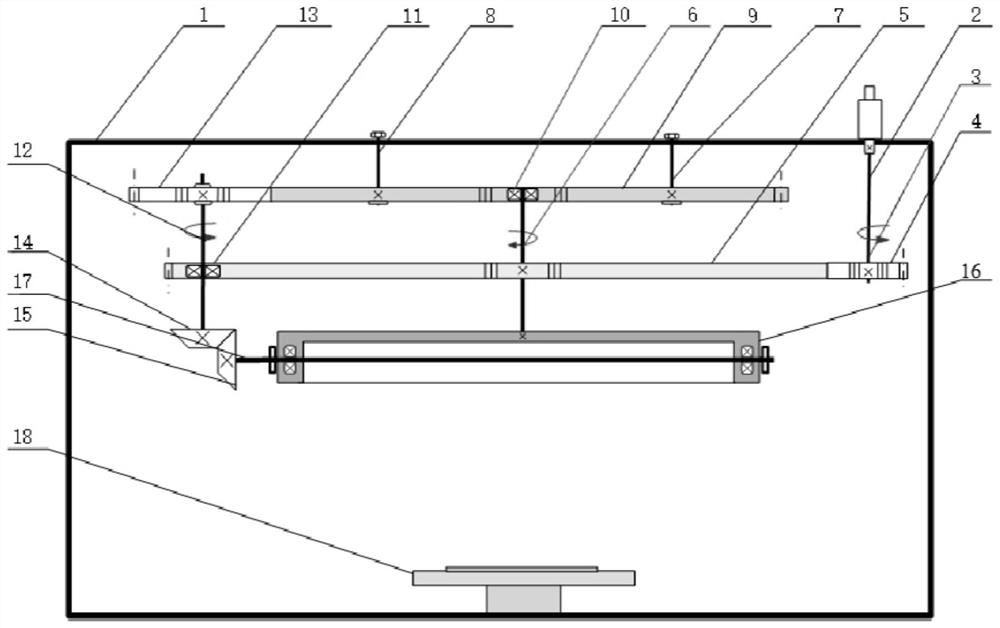

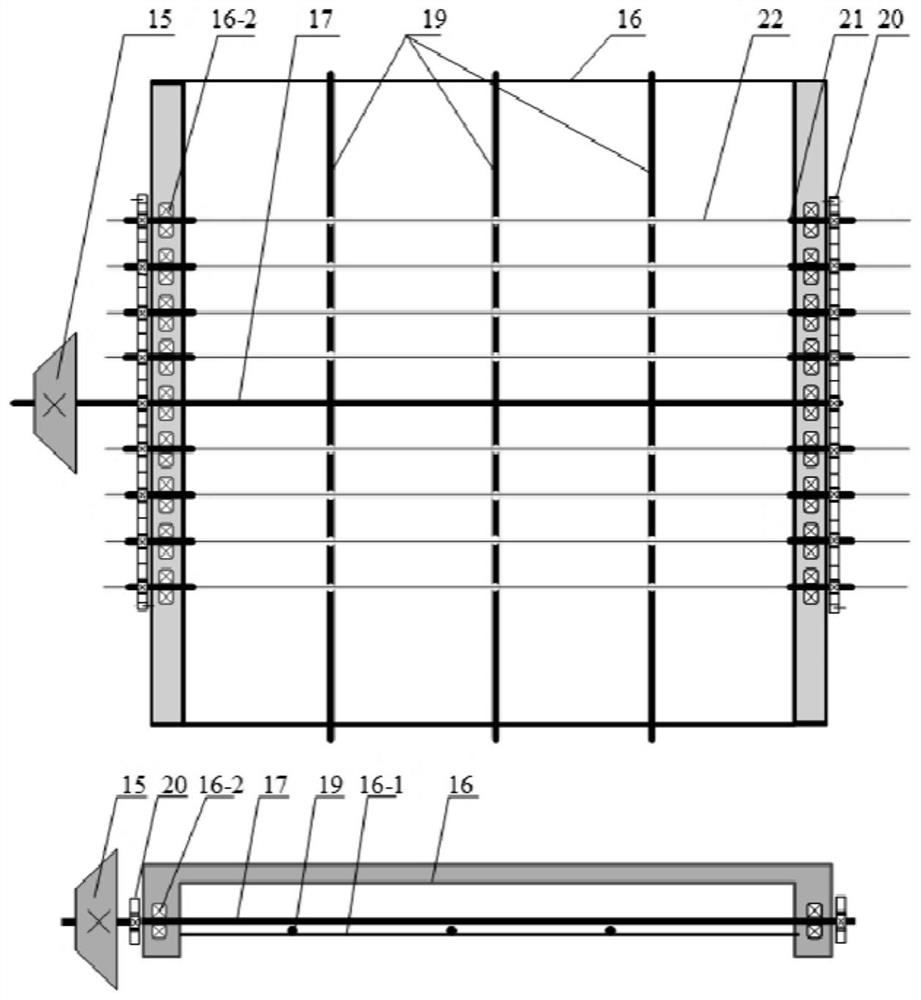

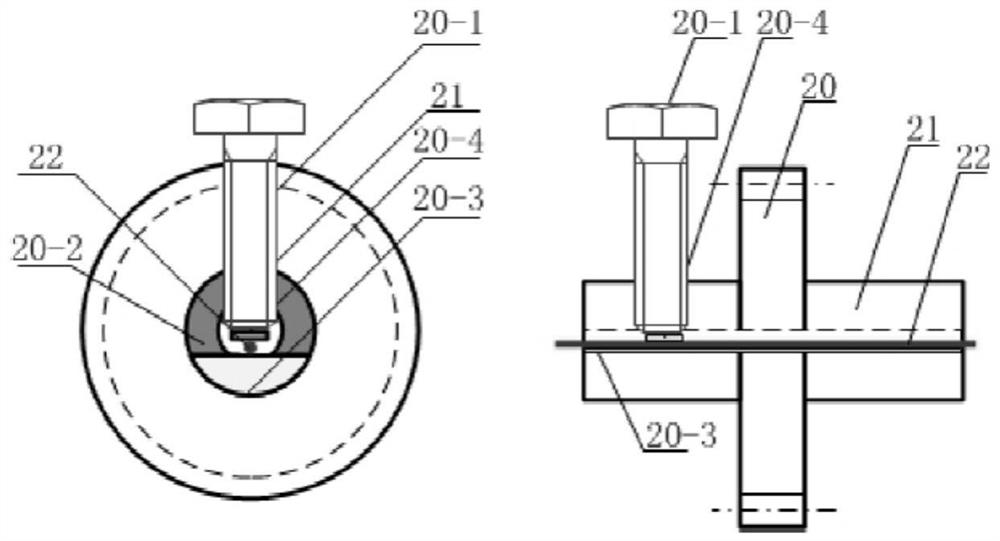

[0030] figure 2 A schematic diagram of the optical fiber clamping device provided by the present invention is given, including: a rotating support steel shaft 17, a power transmission bevel tooth 15, a clamping frame 16, a detachable grooved support rod 19, an optical fiber clamping gear 20, and an optical fiber 22 to be coated; The frame 16 includes a clamp frame side support bar 16-1 and a clamp built-in bearing 16-2, wherein the optical fiber 22 to be coated passes through the image 3 The shown optical fiber clamp gear is fixed with a hollow shaft 21 and supporting screws. There are two ways to fix the optical fiber 22 to be coated and the optical fiber clamp system. One way is to fix both ends of the optical fiber with the optical fiber clamp gear 20. By rotating the supporting steel shaft 17, the gears at both ends rotate at the same angular velocity. In this way, the optical fiber is fixed. The coating can maximize the length of the coating; another way is to fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com