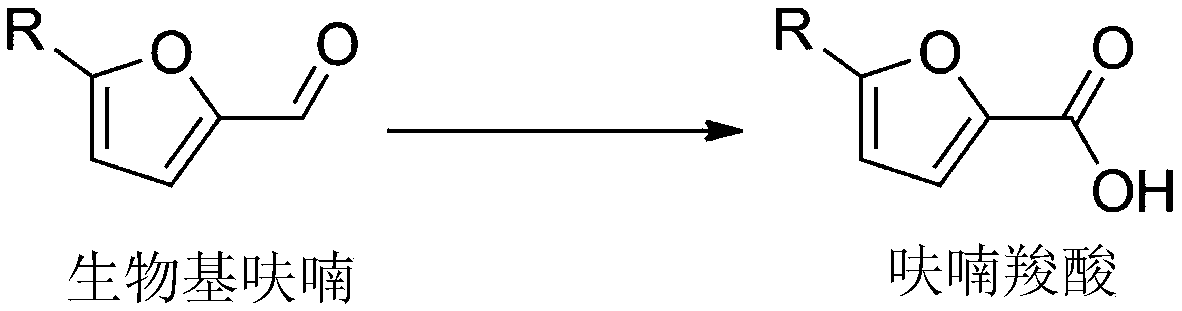

Aldehyde dehydrogenases, gene thereof, construction of recombinant strain and application of recombinant strain in synthesis of furancarboxylic acid

A technology of aldehyde dehydrogenase and furan carboxylic acid, which is applied in the field of genetic engineering technology and biocatalysis, can solve the problems of reduced conversion efficiency and prolonged reaction time, and achieve the effects of simple production process, high production efficiency and mild production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Mining of Aldehyde Dehydrogenase Encoding Genes

[0044] In order to dig out the key enzymes in the genome of C. testosteroni SC1588 that can catalyze the oxidation of bio-based furan to furan carboxylic acid, Shenzhen Huada Gene Technology Service Co., Ltd. was entrusted to sequence the draft genome of C. testosteroni SC1588. According to Functional annotation of the predicted coding sequence, mining five aldehyde dehydrogenase genes from the genome, namely CtCALDH1 gene, CtCALDH2 gene, CtVDH1 gene, CtVDH2 gene and CtSAPDH gene.

Embodiment 2

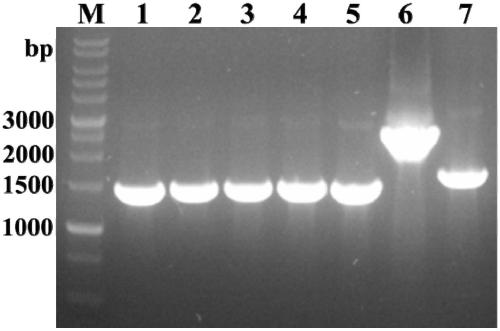

[0046] Construction of recombinant bacteria

[0047] (1) Using the genomic DNA of Comamonas testosteroni SC1588 as a template, the full-length sequences of CtCALDH1, CtCALDH2, CtVDH1, CtVDH2 and CtSAPDH genes were amplified by designing specific primers;

[0048] (2) connecting the aldehyde dehydrogenase gene into the expression vector pET-28a to obtain a recombinant plasmid;

[0049] (3) The recombinant plasmid verified by sequencing was transformed into the expression host E.coli BL21(DE3), and the recombinant bacteria E.coli BL21(DE3)_CtCALDH1, E.coli BL21(DE3)_CtCALDH2, E.coli BL21(DE3)_CtCALDH2, E .coli BL21(DE3)_CtVDH1, E.coli BL21(DE3)_CtVDH2 and E.coli BL21(DE3)_CtSAPDH.

[0050] Table 1 Primer Information

[0051] primer name

Embodiment 3

[0053] Inducible expression of aldehyde dehydrogenase

[0054] The recombinant bacteria obtained in Example 2 were inoculated into 30 mL of LB liquid medium containing 50 μg / mL kanamycin (tryptone 10 g / L, yeast extract 5 g / L, sodium chloride 10 g / L, pH 7.2) , incubated at 37°C and 180rpm for 12h. Then, 1% of the inoculum was inoculated into 100 mL of LB medium containing 50 μg / mL kanamycin, and cultured at 37° C. and 180 rpm. When the OD of the bacterial solution 600 When reaching 0.6 to 0.8, IPTG was added to make the final concentration 0.1 mM, and the cells were incubated at 18° C. and 160 rpm for 20 h. After the culture, the cells were centrifuged at 8000 rpm and 4°C for 5 min to collect the bacterial cells, and the cells were washed twice with 0.85% normal saline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com