Fast-setting epoxy impregnating adhesive and preparation method thereof

A technology of impregnating glue and epoxy, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of slow curing speed of impregnating glue, time required for early strengthening of impregnating glue, and no obvious rigid requirements for basic performance, etc. Achieve the effect of high reactivity and good moisture and heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

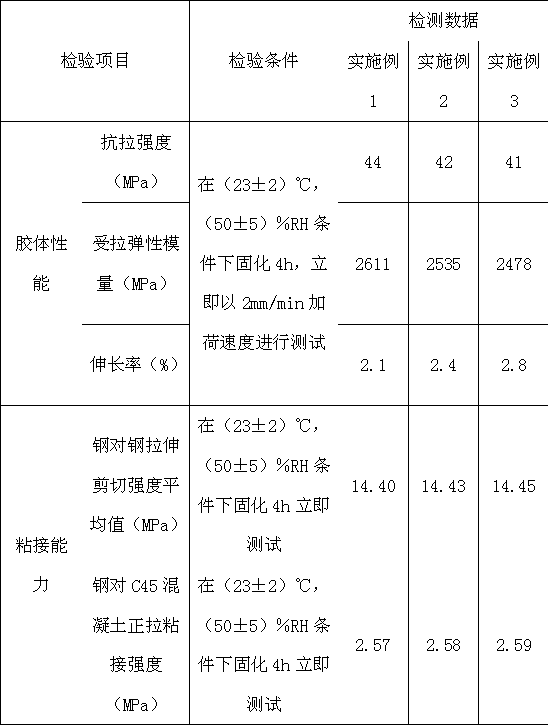

Examples

Embodiment 1

[0017] A fast-curing epoxy impregnating glue, which is composed of component A and component B at a ratio of 1:0.5 by weight. The components of component A are as follows: bisphenol A type epoxy 100 parts of resin, 0.5 parts of silane coupling agent, 1 part of thixotropic agent, the components of B component are as follows by weight: 100 parts of modified polyamine curing agent.

[0018] The epoxy value of the bisphenol A type epoxy resin is 0.48-0.54.

[0019] The modified polyamine curing agent is a modified polyamine curing agent that still has good curing ability at 5°C and has an active hydrogen equivalent of 100-160.

[0020] The silane coupling agent is selected from γ-aminopropyl triethoxysilane (KH-550), γ-glycidyl ether propyl triethoxysilane (KH-560), γ-propyltrimethoxysilane At least one of base silane (KH-570).

[0021] The present invention also provides a preparation method of fast-curing epoxy impregnating glue, comprising the steps of:

[0022] S1: Preparat...

Embodiment 2

[0026] A fast-curing epoxy impregnating glue, which is composed of component A and component B at a ratio of 1:0.6 by weight. The components of component A are as follows: bisphenol A type epoxy 100 parts of resin, 1 part of silane coupling agent, 3 parts of thixotropic agent, the components of component B are as follows by weight: 100 parts of modified polyamine curing agent.

[0027] The epoxy value of the bisphenol A type epoxy resin is 0.48-0.54.

[0028] The modified polyamine curing agent is a modified polyamine curing agent that still has good curing ability at 5°C and has an active hydrogen equivalent of 100-160.

[0029] The silane coupling agent is selected from γ-aminopropyl triethoxysilane (KH-550), γ-glycidyl ether propyl triethoxysilane (KH-560), γ-propyltrimethoxysilane At least one of base silane (KH-570).

[0030] The present invention also provides a preparation method of fast-curing epoxy impregnating glue, comprising the steps of:

[0031] S1: Preparatio...

Embodiment 3

[0035] A fast-curing epoxy impregnating glue, which is composed of component A and component B at a ratio of 1:0.7 by weight. The components of component A are as follows: bisphenol A type epoxy 100 parts of resin, 2 parts of silane coupling agent, 5 parts of thixotropic agent, the components of component B are as follows by weight: 100 parts of modified polyamine curing agent.

[0036] The epoxy value of the bisphenol A type epoxy resin is 0.48-0.54.

[0037] The modified polyamine curing agent is a modified polyamine curing agent that still has good curing ability at 5°C and has an active hydrogen equivalent of 100-160.

[0038] The silane coupling agent is selected from γ-aminopropyl triethoxysilane (KH-550), γ-glycidyl ether propyl triethoxysilane (KH-560), γ-propyltrimethoxysilane At least one of base silane (KH-570).

[0039] The present invention also provides a preparation method of fast-curing epoxy impregnating glue, comprising the steps of:

[0040] S1: Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com