Difficult-flammble polycarbonate composition and preparation method thereof

A polycarbonate and polycarbonate resin technology, applied in the field of engineering plastics, can solve the problems affecting the toughness and heat resistance of PC resins, the limitation of the use of aromatic phosphate ester flame retardants, and the decline of the mechanical properties of resins, so as to improve the toughness. The effect of retention, flame retardant performance improvement, and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0028] The present invention will be described in detail below in conjunction with examples.

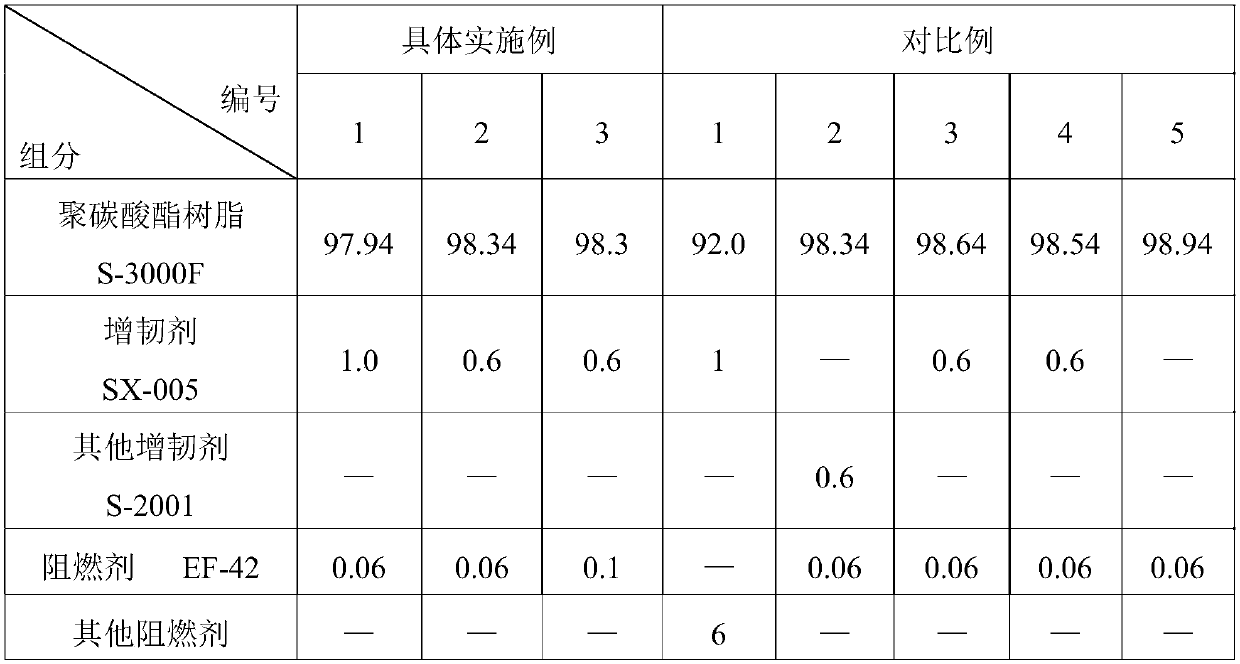

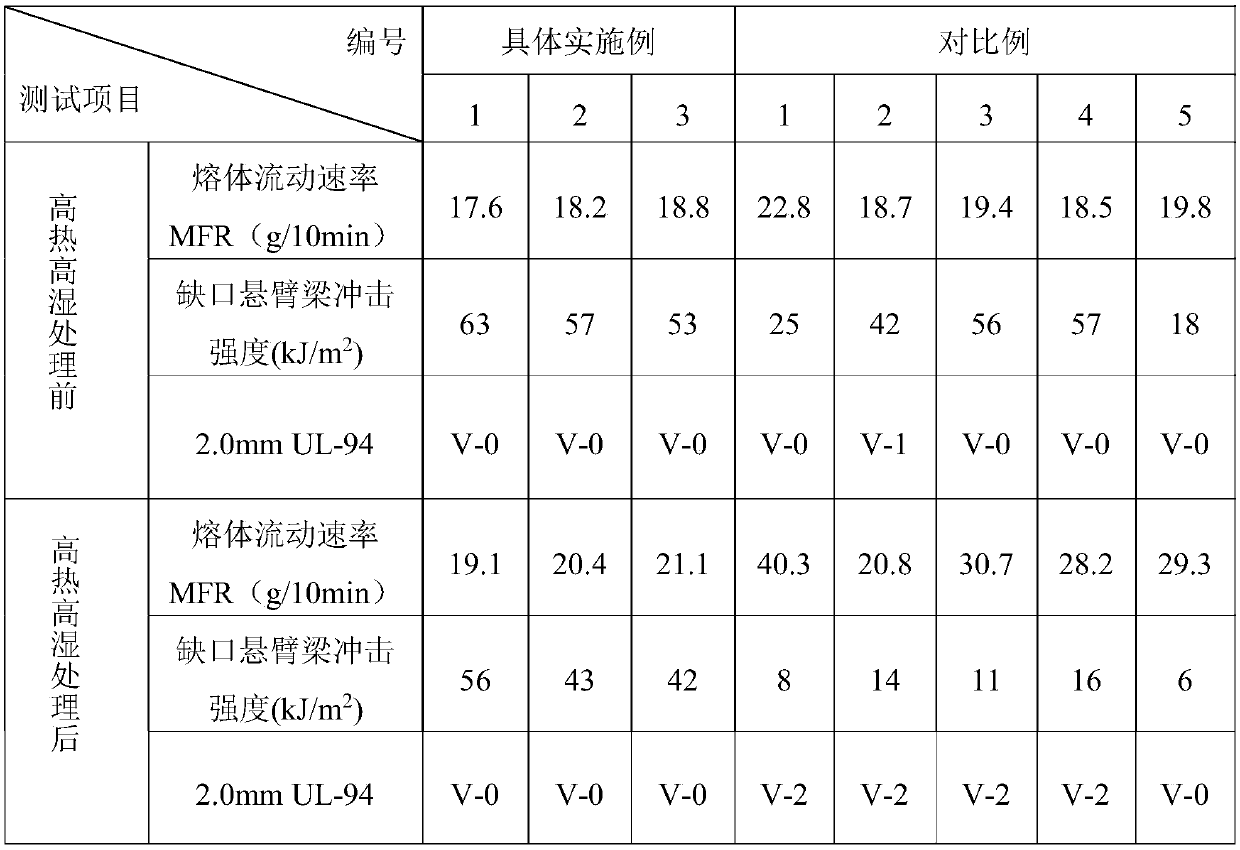

[0029] In embodiment 1-3 of the present invention and comparative example 1-5: polycarbonate resin (PC resin) selects the PC S-3000F (Mitsubishi of Japan) that viscosity-average molecular weight is 22000 for use; Toughener selects the SX- 005, the other toughening agent is S-2001 from Mitsubishi Rayon; the flame retardant is EF-42 (Mitsubishi), and the other flame retardant is PhireGuard BDP (Jiangsu Yake); the anti-hydrolysis agent is Stabaxol P (Rheinland Chemical ). The lubricant in othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com